Concrete is one of the most widely used building materials in the world, forming the backbone of modern infrastructure. From skyscrapers and bridges to residential homes and pavements, concrete is relied upon for its strength, durability, and versatility. However, concrete alone is brittle and lacks tensile strength, meaning it can crack under tension. To overcome this, reinforcement is introduced, usually in the form of steel bars (rebar). While rebar itself provides tensile strength, its effectiveness relies heavily on how securely it is positioned before and during the concrete pour. This is where tie wire plays an indispensable role.

MỤC LỤC BÀI VIẾT

What Is Tie Wire?

Tie wire is a type of soft, flexible, and easily bendable steel wire used to secure reinforcement bars (rebar) in place before pouring concrete. It is typically made of low-carbon steel, annealed for pliability, which allows workers to twist, knot, and tighten it without breaking. Tie wire is available in coils, precut bundles, or rolls, making it easy to transport and handle at construction sites. Common diameters range from 16 to 20 gauge (1.6 mm to 1.0 mm) depending on application.

Different finishes exist to suit various conditions:

- Black annealed: Soft and flexible, the most commonly used for general rebar tying.

- Galvanized: Coated to resist corrosion, ideal for outdoor and humid environments.

- Stainless steel: High durability and corrosion resistance, used in marine or chemical environments.

- PVC-coated: Provides additional protection and flexibility.

The Role of Tie Wire in Concrete Reinforcement

The importance of tie wire cannot be overstated in reinforced concrete construction. Its primary purpose is to hold rebar in the correct position until the concrete is poured and cured. Without tie wire, rebar could shift, reducing structural integrity and potentially leading to premature failures. Here are the key reasons why tie wire matters:

- Positioning and Stability

Concrete structures require precise placement of reinforcement bars. Tie wire ensures rebar remains fixed at the specified spacing and alignment, even under the stress of pouring heavy concrete. - Load Distribution

Reinforcement bars need to stay in place to properly absorb tensile forces. Tie wire helps maintain the grid structure of rebar, ensuring that load distribution remains uniform across the entire concrete element. - Cost-Effectiveness

Tie wire is inexpensive but crucial. Using it prevents costly errors, structural weaknesses, and the need for rework, saving time and money on projects. - Adaptability

Tie wire can be cut, bent, and twisted easily, making it versatile for various shapes and sizes of rebar configurations. - Safety and Durability

A secure rebar cage minimizes the risk of collapse during the concrete pour, ensuring the safety of workers and the longevity of the structure.

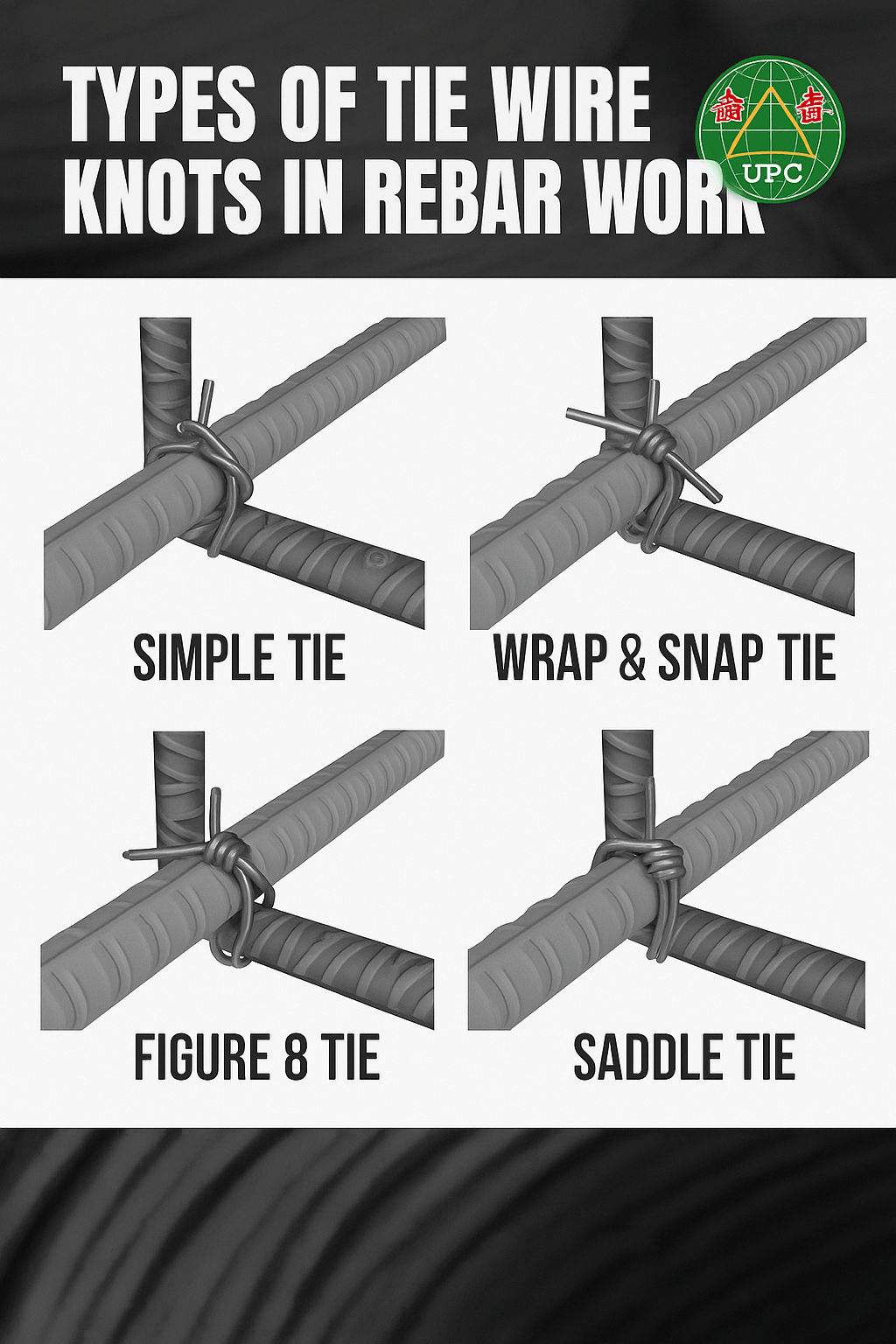

Types of Tie Wire Knots in Rebar Work

There are several tying techniques, depending on structural requirements and worker preferences. Common types include:

- Snap (Single) Tie: A quick and simple method, suitable for light-duty connections.

- Double Snap Tie: Provides extra security, used when more stability is needed.

- Wrap and Snap Tie: Involves looping the wire twice around the rebar, ensuring greater tightness.

- Saddle Tie: Often used for cross points where bars intersect, providing a snug fit.

- Figure-Eight Tie: Used in more complex intersections for strong fastening.

The choice of knot depends on structural demands, but in all cases, tie wire ensures that rebar grids maintain their integrity during concrete placement.

Tools for Applying Tie Wire

Although tie wire can be tied manually using pliers, construction projects often require speed and consistency. Tools commonly used include:

- Rebar tying pliers: Manual pliers used for twisting and cutting wire.

- Rebar tying hooks: Simple hooks that quickly twist tie wire into knots.

- Automatic rebar tying machines: Battery-operated devices that tie wire around rebar quickly and consistently, saving significant labor time on large projects.

These tools make the process more efficient while ensuring uniformity in knot strength.

Standards and Specifications

In construction, tie wire is manufactured and applied in accordance with industry standards to ensure safety and durability. Some relevant standards include:

- ASTM A853: Covers low-carbon steel wire for general use.

- BS 443 (British Standard): Pertains to steel wire for concrete reinforcement.

- EN 10016 (European Standard): Regulates technical delivery conditions for non-alloy steel wire rods.

Contractors must ensure that steel wire used in projects complies with local or international building codes, especially in large-scale infrastructure.

Tie Wire vs. Alternatives

While tie wire is the most common method for securing rebar, there are alternatives:

- Plastic clips or spacers: Quick to install but less versatile.

- Welding: Provides strong joints but is expensive and unsuitable for all environments, especially where rebar flexibility is required.

- Mechanical fastening systems: More advanced but costly.

Despite these options, steel wire remains the most widely adopted method due to its balance of cost, ease of use, and effectiveness.

Challenges and Best Practices

Although simple, the use of tie wire requires attention to detail:

- Avoid over-tightening: This may cause the rebar to shift or the wire to snap.

- Consistent knotting: Uniform tying prevents weak spots in the reinforcement grid.

- Use protective coatings: In environments with high moisture or chemicals, galvanized or stainless steel wire should be used to prevent corrosion.

- Training workers: Skilled labor ensures knots are tied correctly and securely.

Case Study: Tie Wire in High-Rise Construction

In high-rise buildings, where rebar cages extend vertically and horizontally across multiple floors, tie wire is critical for stability. During one project in Europe, engineers reported that improper rebar tying caused significant misalignments, leading to delays and rework. After switching to automatic tying machines and standardized wire types, the project maintained precision alignment and reduced labor hours by 30%. This highlights how tie wire, though inexpensive, plays a vital role in avoiding costly mistakes.

The Future of Tie Wire in Construction

While advancements in technology are introducing new fastening methods, steel wire is unlikely to be replaced soon. Its simplicity, low cost, and adaptability make it irreplaceable in most construction projects. However, innovations such as biodegradable steel wire coatings and robotic tying machines may improve sustainability and efficiency in the years ahead.

Conclusion

Tie wire may appear to be a small, insignificant item compared to the massive structures it helps build, but its role in concrete reinforcement is crucial. Without it, rebar would shift during concrete placement, compromising the safety and durability of the entire structure. From small residential projects to large infrastructure developments, tie wire ensures that reinforcement remains strong, aligned, and effective.

In construction, even the simplest tools and materials can make the greatest difference. Tie wire, though often overlooked, truly matters in concrete reinforcement — it is the silent safeguard of modern structures.

Contact information

UNITED NAIL PRODUCTS CO., LTD

Address: 16A8, Tra Noc Industrial Zone 1, Tra Noc Ward, Binh Thuy District, Can Tho City, VietNam

Phone: (+84) 986 831838; (+84) 292 242165

Email: sales5@unitednail.com

Thank you for reading this article, hope the information is useful to you.