When you think of global construction, towering steel structures or large-scale machinery might come to mind. Yet behind every beam, panel, or plank, there are thousands—sometimes millions—of nails and wires silently doing their job. These small components carry an enormous responsibility: holding the structure together.

As the demand for fasteners continues to rise in construction, packaging, and manufacturing industries, so does the need for trustworthy suppliers. In recent years, Vietnam has emerged as a top destination for buyers seeking reliable, high-quality nail products. But why? What sets Vietnamese factories apart?

Let’s explore the reasons global buyers—from the United States to Mexico and Europe—are shifting their sourcing strategies and putting their trust in Nail Factories in Vietnam.

MỤC LỤC BÀI VIẾT

Vietnam’s Manufacturing Evolution: From Local to Global

Vietnam’s journey from a local-focused producer to a globally recognized manufacturing hub didn’t happen overnight. The last two decades have seen a steady transformation fueled by:

Investment in infrastructure and ports

Pro-business government policies

Growing skilled labor force

Increasing adoption of international standards

In the nail manufacturing sector, this shift is especially evident. Vietnamese companies have moved from basic production lines to advanced, semi-automated factories capable of meeting stringent international requirements.

The result? Today, Vietnamese nail factories export millions of tons of products annually, serving major markets such as the U.S., Canada, Mexico, Japan, Australia, and the Middle East.

Quality that Meets and Often Exceeds—Expectations

Modern buyers are no longer just looking for low prices. They’re seeking consistency, performance, and compliance with technical standards.

Vietnamese factories, particularly companies like United Nail Products Co., Ltd, have made quality a core competitive edge. Here’s how:

🔹 Advanced Production Techniques

Nail forming machines, wire drawing lines, zinc-coating systems, and annealing furnaces have all been upgraded to ensure strength, corrosion resistance, and precision.

🔹 International Certifications

Products meet ASTM (American) and JIS (Japanese) standards. Many Vietnamese nail factories maintain ISO 9001 certifications and provide batch-level testing reports.

🔹 Dedicated Quality Control

Instead of random sampling, QC teams monitor every production stage — from raw wire to packaging — ensuring defects are caught before shipment.

This emphasis on quality is not only about compliance, but reputation. For Vietnamese exporters, every nail represents their national credibility in the global market.

The Price–Performance Sweet Spot

Vietnam offers one of the most attractive value propositions in the nail industry. While China remains a major player, many buyers are turning to Vietnam for better price-performance balance.

Why?

Lower labor costs with high workmanship

In-house wire drawing capabilities

Cost-effective logistics via regional ports

Reduced tariffs thanks to Vietnam’s trade agreements (like EVFTA, CPTPP)

This makes Vietnamese products ideal for cost-sensitive buyers in North America and Latin America—especially for mass-volume items like coil nails or bulk roofing nails.

Full Product Range, Full Customization

Vietnamese manufacturers understand that no two buyers are the same. Whether a client needs high-load collated nails for construction, or soft black annealed tie wire for bundling — customization is king.

Here’s a typical catalog from top factories like United Nail Products:

| Product Category | Description |

|---|---|

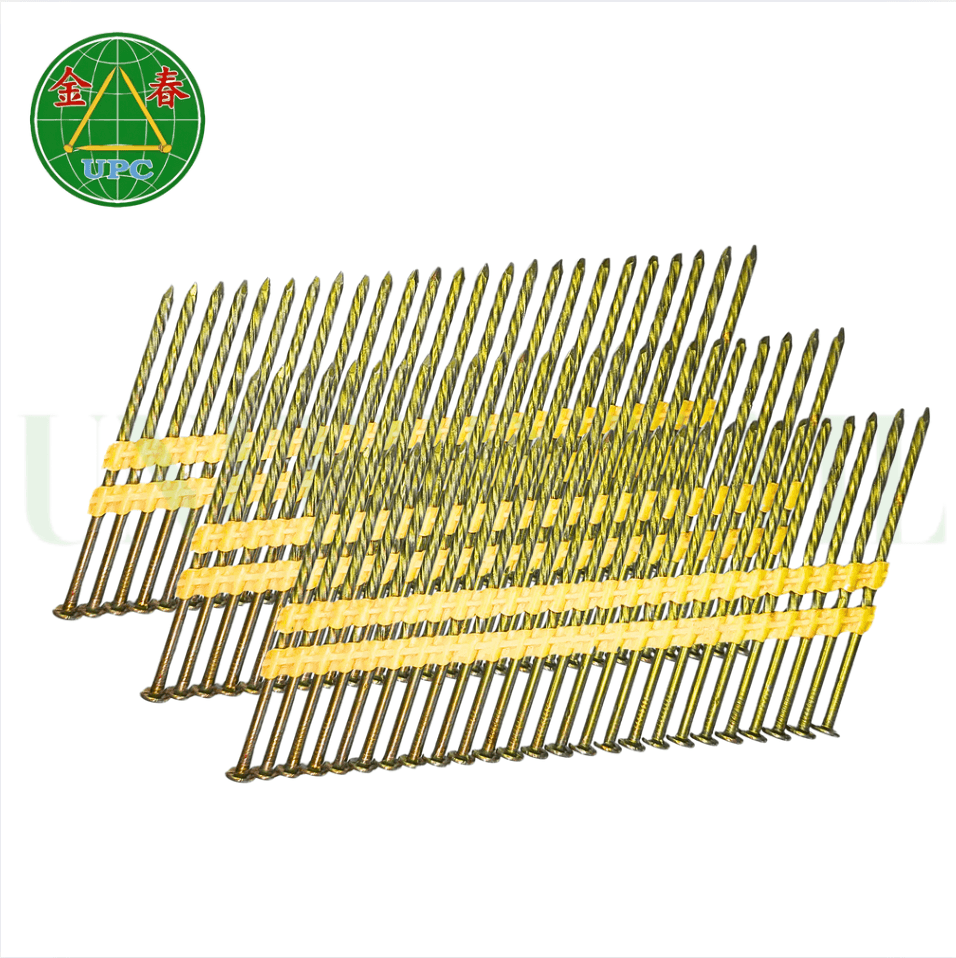

| Coil Nails | Wire collated, screw or ring shank, electro-galvanized or hot-dip |

| Coil Roofing Nails | Large head, short length, smooth shank, used in roofing guns |

| Plastic Strip Nails | Collated at 20°–22°, used for framing and decking |

| Common Nails | Bulk packed, general construction |

| Black Annealed Tie Wire | Soft, ductile, low carbon wire, available in coils or cut lengths |

And if the buyer has a sample? Vietnamese factories will replicate it exactly—right down to thread pitch, shank profile, or box design.

Responsive Communication & After-Sales Support

One of the biggest frustrations for international buyers? Lack of clear communication and poor service after purchase.

Vietnamese suppliers are changing that.

Many have bilingual export teams who provide:

Fast quotation turnaround (within 24–48 hours)

Detailed PI and order confirmation process

Photos and videos of packing before shipment

Prompt replies via email, WhatsApp, or video call

Technical support after delivery

Buyers feel heard, understood, and supported — which builds long-term relationships.

Timely Delivery, Even in a Global Crisis

During COVID-19 and the container shortage of 2021–2022, many buyers turned to Vietnam for its resilience in logistics. Ports like Hai Phong, Cat Lai, and Cai Mep remained functional, and factories worked double shifts to meet deadlines.

Vietnam’s location near key Asian sea routes also gives it an edge in shipping speed, especially to Pacific markets.

Case Study: United Nail Products Co., Ltd

Let’s look at a real example of why global buyers trust Vietnamese nail factories.

United Nail Products, with over 25 years of export experience, is one of Vietnam’s most reputable manufacturers in the field. Here’s what sets them apart:

🏭 Capacity

3,000+ tons/month output

Multiple coil nail lines & annealed wire production

In-house packaging & printing facility

📦 Product Range

Coil nails

Roofing nails

Plastic strip nails

Bulk nails

Common nails

Tie wire in coils or straight cut

🌍 Global Reach

Exporting to over 12 countries

Strong presence in the U.S., Mexico, Canada, and Australia

Custom packaging for each market

🧾 Buyer Experience

A recent buyer from Mexico had a roofing nail sample but no technical drawing. United Nail Products reproduced it within 2 days, sent photos for approval, and delivered on time with consistent quality. That buyer is now in their 6th consecutive container order.

What Do Global Buyers Say?

“We were sourcing from China but switched to Vietnam due to delays. United Nail Products gave us better service and faster turnaround.”

– Construction Wholesaler, Texas, USA

“We appreciated the flexibility. We asked for black wire in 1.6mm cut-to-length pieces, and they nailed it perfectly.”

– Industrial Distributor, Jalisco, Mexico

“The packaging was clean, consistent, and arrived without damage. It’s clear they care about details.”

– Roofing Supply Importer, Brisbane, Australia

How to Choose the Right Nail Factories in Vietnam

If you’re a global buyer considering Vietnam, here’s what to look for:

✅ Experience with export documentation

✅ Consistent quality (not just one-time samples)

✅ Strong communication team

✅ Factory visit availability (in-person or video)

✅ Ability to handle OEM/ODM requests

✅ Competitive pricing without hidden costs

Bonus: Ask if they can send you a full pre-shipment photo report — this shows professionalism and transparency.

Deep Dive into Nail Types and Applications

To show the depth of nail factories in Vietnam, here’s a breakdown of major nail types and where they are used globally:

Coil Nails

Used in framing, decking, fencing, and pallets

Common in U.S., Canada, and Australia

Available in ring shank, screw shank, smooth shank

Coil Roofing Nails

Used for asphalt shingles, felt, and soft roofing materials

Short, thick nails with large head

Major market: USA, Mexico

Plastic Strip Nails

Popular in pneumatic framing tools

20°–22° collation angle

Packed in sticks, ideal for wooden frames and crates

Common Nails

General purpose nails for wood-to-wood connection

Packed in bulk (25–50kg bags)

Competitive segment for Africa, South Asia

Black Annealed Tie Wire

Flexible steel wire used for rebar tying, packaging, bundling

Soft & ductile after annealing

Common sizes: 1.59mm – 3.76mm

Available in 3.5lb coils, 100lb rolls, or cut wire (tie lengths)

Each product type requires its own production process and quality assurance — Vietnamese factories like United Nail Products have mastered the full spectrum.

Sustainability and Environmental Commitment

Today’s buyers also care about the eco-impact of their supply chain.

Many Vietnamese factories are adopting greener practices, including:

Recycled steel wire rods for nail production

Closed-loop water systems in galvanizing lines

Use of eco-friendly packaging materials

Efficient energy use in annealing & heating processes

Some factories are also pursuing ISO 14001 environmental certifications to ensure they minimize waste and pollution.

This is a growing competitive edge, especially for buyers in Europe who must meet strict sustainability regulations.

Behind the Scenes: The People Who Power Nail Production

What really makes Vietnamese nail factories successful? The people.

From engineers maintaining precise machinery, to QA inspectors, to export officers answering customer emails at midnight — this is a team effort.

At United Nail Products, for instance:

Over 200 skilled workers are trained regularly on safety and quality

The R&D team works with clients to develop new nail specs and packing formats

Export staff speak English for smoother client interactions

This human touch—combined with technical strength—is what builds real trust.

Future Outlook: Vietnam’s Nail Industry in 2030

Vietnam’s nail manufacturing sector is poised for even greater growth in the coming decade.

🚀 What’s Driving Growth:

Increasing demand from Latin America and Africa

Relocation of factories from higher-cost regions

Expanding product lines: stainless steel nails, specialty fasteners

Digitalization of export processes (e-catalogs, online B2B sales)

Vietnam is no longer a low-cost backup. It’s becoming a strategic hub for global nail supply.

Final Thoughts: Small Nails, Strong Connections

Whether you’re sourcing for industrial framing, roofing, packaging, or general construction — choosing the right nail supplier matters. Nail factories in Vietnam bring more than just cost savings. They bring trust, transparency, and tailored solutions.

United Nail Products Co., Ltd stands at the forefront of that trust — with decades of experience, a commitment to quality, and a vision for the future.

Conclusion: Vietnam Has “Nailed” Global Expectations

It’s no longer a secret — Vietnam has earned its place as a top-tier nail manufacturing hub. Thanks to a blend of quality, price, flexibility, and service, the country is proving that even the smallest products can have the biggest impact.

And among the trusted players, United Nail Products Co., Ltd stands out for its commitment to excellence.

If you’re ready to source reliable coil nails, roofing nails, or tie wire — it may be time to look beyond the usual and turn your attention to Vietnam.

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production

Thank you for taking the time to read this article. We hope the information proves helpful to you.