In today’s fast-paced world, the demand for efficient and reliable tools in construction and industrial applications is ever-growing. One of the most effective ways to improve productivity while maintaining quality is by utilizing the right combination of materials and tools. When it comes to nailing tasks, using Plastic Strip Nails in combination with a nail gun can save up to 20% of both time and effort, enhancing your overall work efficiency.

MỤC LỤC BÀI VIẾT

Understanding Plastic Strip Nails and Their Benefits

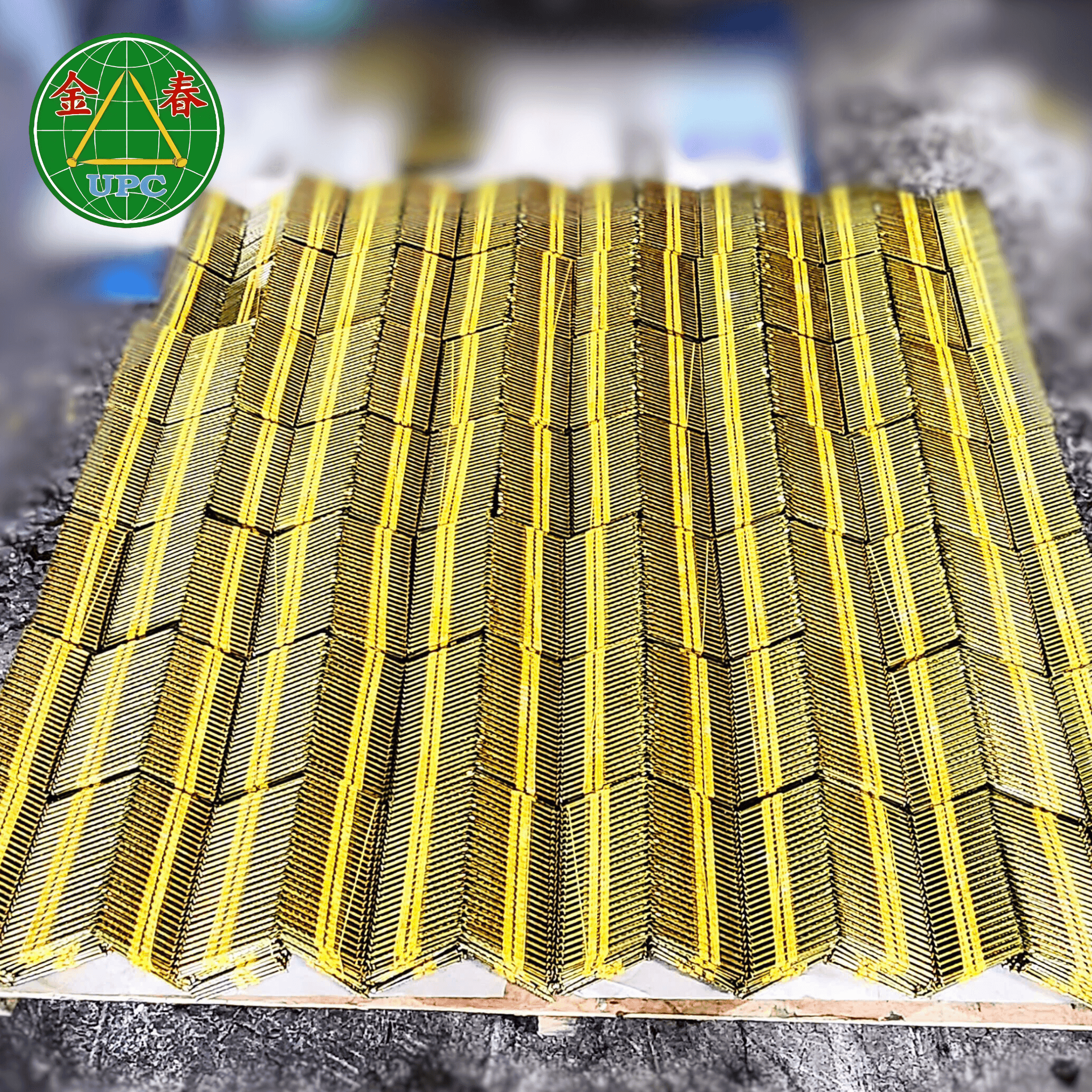

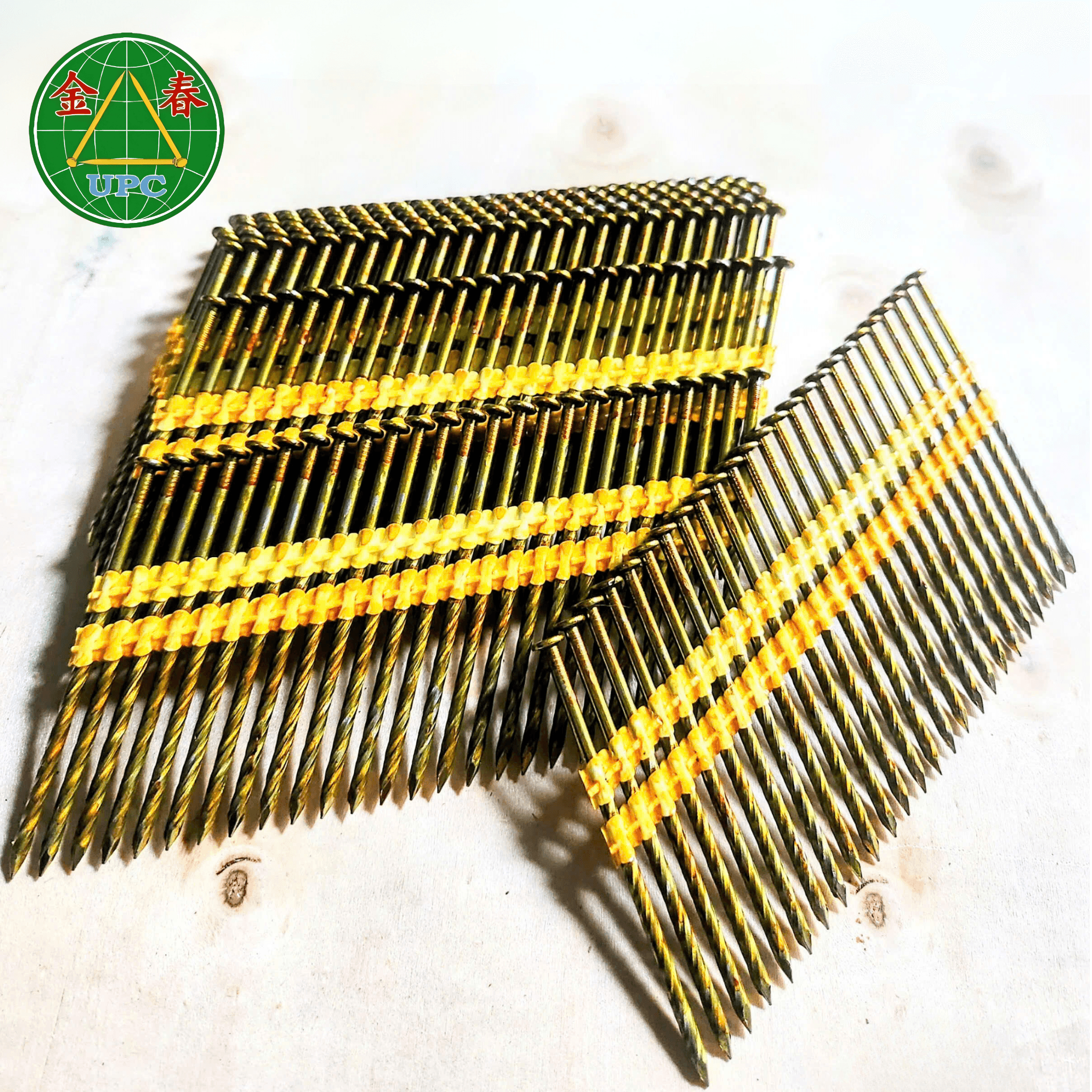

Plastic Strip Nails are a type of collated nail, designed to be used with a nail gun. They are typically arranged in a strip, with each nail connected by a durable plastic strip that holds the nails together. This design allows for quick, continuous loading and firing, reducing downtime and improving the speed of work.

The primary advantage of Plastic Strip Nails lies in their ability to be loaded easily and fired rapidly by a nail gun. This creates a more efficient workflow, especially for large projects where a high volume of nails is required. By using these nails, you can drastically reduce manual labor, avoid the hassle of individually loading each nail, and improve overall productivity.

How Plastic Strip Nails Improve Efficiency

One of the main reasons why Plastic Strip Nails are so effective in saving time is their design. Traditional loose nails often require workers to manually handle each nail, which can slow down the process. With Plastic Strip Nails, the strip ensures that nails are readily available, allowing workers to focus solely on their task. This results in a smoother workflow, fewer interruptions, and ultimately, quicker completion of tasks.

The use of Plastic Strip Nails in combination with a nail gun also eliminates the need for frequent reloading, reducing the downtime that typically occurs when switching out nails. This translates to an uninterrupted workflow, meaning more work gets done in less time. The reduced need for manual handling of nails allows workers to stay focused on the task at hand without worrying about replenishing their supplies constantly.

Time-Saving Through Plastic Strip Nails and Nail Guns

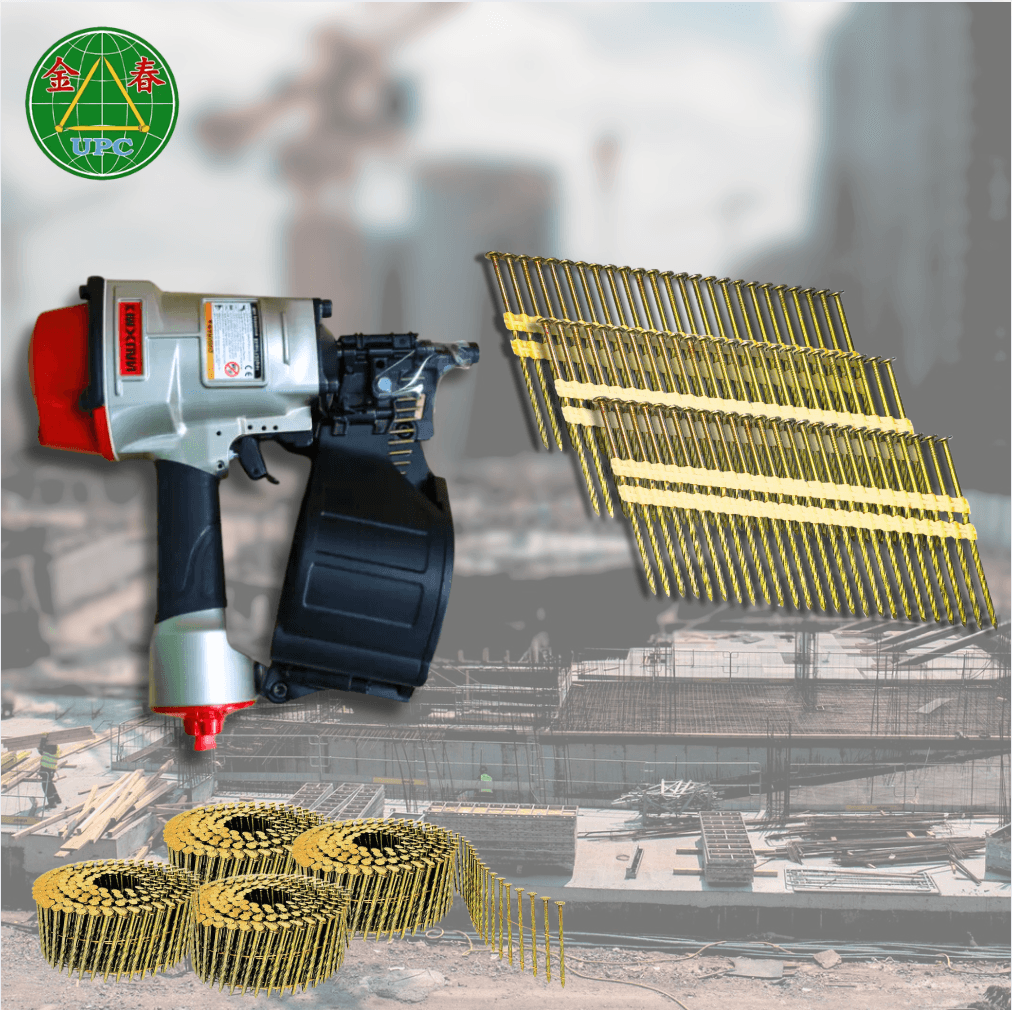

When using a nail gun with Plastic Strip Nails, the process of nailing becomes significantly faster. For example, a worker using a hammer would need to pick up each nail individually and position it, which takes time and can lead to fatigue. In contrast, a nail gun with Plastic Strip Nails eliminates this step. The nails are automatically loaded into the gun, and with a simple press of the trigger, multiple nails are driven in quickly and accurately.

This combination reduces the amount of time spent on each individual task, whether it’s framing, roofing, or other general construction jobs. As a result, workers can complete larger projects in a fraction of the time it would take with traditional methods, ultimately leading to a faster project turnaround.

Plastic Strip Nails: Reducing Manual Labor and Effort

Another significant benefit of using Plastic Strip Nails in conjunction with a nail gun is the reduction in manual effort. Traditional methods of nailing involve significant hand and arm strength, especially when performing repetitive tasks. This can lead to worker fatigue, which affects both speed and the quality of work.

By switching to Plastic Strip Nails, workers can reduce the physical strain on their bodies. Since the nail gun handles the driving of the nails, the worker’s primary task is to guide the tool, minimizing physical effort. This ergonomic advantage not only speeds up the process but also helps prevent injuries that could arise from repetitive motion or overexertion.

The use of Plastic Strip Nails allows workers to focus on precision and efficiency rather than tiring physical labor. This is especially beneficial in environments where a high level of accuracy is required, such as framing and assembly work. With less effort required to load and drive nails, workers can maintain a high level of performance throughout the day.

The Cost-Efficiency of Plastic Strip Nails and Nail Guns

Another factor that contributes to the overall efficiency of using Plastic Strip Nails is cost savings. By reducing the time it takes to complete a task, workers can take on more projects, increasing overall output. Additionally, the precision of the nail gun reduces the likelihood of mistakes, which would otherwise require time-consuming corrections.

In comparison to manual nailing methods, the combination of Plastic Strip Nails and a nail gun is far more cost-effective in the long run. While the initial investment in a nail gun may seem higher, the time savings and increased productivity far outweigh the upfront costs. This means that the overall cost per unit of work is reduced, making it a wise investment for businesses in the construction or manufacturing industries.

Plastic Strip Nails: Versatility and Durability

The versatility of Plastic Strip Nails is another key reason why they are so popular in various applications. These nails can be used for a wide range of tasks, from carpentry and framing to roofing and decking. The ability to easily switch between different sizes of Plastic Strip Nails allows workers to tackle different types of projects with a single tool, making the process more streamlined.

In addition to their versatility, Plastic Strip Nails are highly durable. They are designed to withstand the rigors of heavy-duty work, providing a strong, secure hold that ensures the structural integrity of your projects.

Key Factors in Maximizing the Efficiency of Plastic Strip Nails

While using Plastic Strip Nails in combination with a nail gun is already a significant time-saver, there are several additional strategies to further enhance efficiency:

- Regular Maintenance: Keep the nail gun in top condition by performing regular maintenance and cleaning. A well-maintained tool will operate more efficiently and last longer.

- Proper Nail Size Selection: Ensure you are using the correct size and type of Plastic Strip Nails for your specific project. Using nails that are too large or small can cause delays and result in suboptimal performance.

- Training and Skill Development: Properly training workers on how to use a nail gun effectively will ensure faster, more precise results. Skilled workers will make the most of the nail gun’s capabilities, further increasing efficiency.

Conclusion: Achieving 20% Time and Effort Savings

In conclusion, the combination of Plastic Strip Nails and a nail gun offers a highly efficient solution for a variety of tasks. By eliminating the need for manual handling of nails, reducing reloading time, and minimizing physical effort, this combination saves up to 20% of both time and effort compared to traditional methods. This results in faster project completion, improved productivity, and reduced worker fatigue.

The benefits of Plastic Strip Nails extend beyond time and effort savings; they also contribute to cost efficiency, durability, and versatility, making them an ideal choice for professionals in industries ranging from construction to manufacturing. By implementing Plastic Strip Nails and a nail gun into your workflow, you can ensure smoother, faster, and more reliable results.

UNITED NAIL PRODUCTS CO., LTD

Specializing in manufacturing high quality industrial nails and tie wire

Address: 16A8, Tra Noc Industrial Zone 1, Tra Noc Ward, Binh Thuy District, Can Tho City, VietNam

Phone: (+84) 986 831838; (+84) 292 242165

Email: sales5@unitednail.com