In the modern construction industry, selecting high-quality materials suited to specific applications is always a top priority. One of the materials widely trusted in many projects today is Roofing Nails.

Also known as large-head nails, Roofing Nails are designed with a distinctive large head that enhances both load-bearing capacity and grip strength. This product has become an effective solution for projects that require durability and stability. In this article.

MỤC LỤC BÀI VIẾT

What Are Roofing Nails?

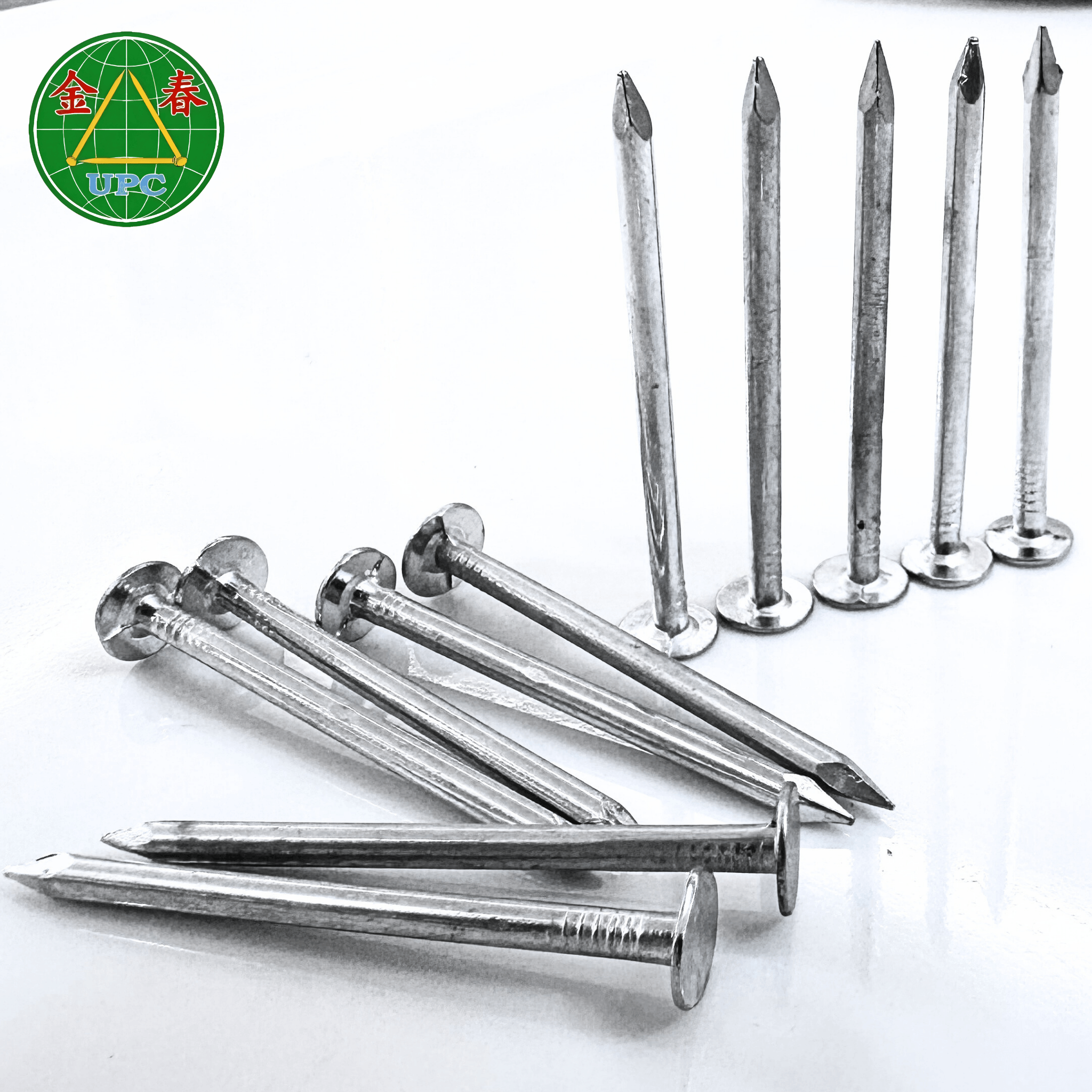

Roofing Nails are specialized nails designed with a larger head compared to regular nails. The large head increases the contact area between the nail and the material surface, improving the nail’s grip when driven into surfaces like wood, metal, or other construction materials. The large head also allows the nail to withstand strong impact forces, providing stability during construction.

Structure and Outstanding Technical Features

Roofing Nails offer several technical advantages that enhance their performance:

- Large, Rounded Head: The wide, round head provides a larger contact surface, ensuring more secure fastening of materials. The heads are aesthetically pleasing and uniformly shaped, ensuring high stability when driven into surfaces.

- Sharp 30-degree Tip: The nail’s sharp tip at a 30-degree angle allows easy penetration into hard surfaces without causing damage or deformation.

- Yellow Electroplating: This coating gives the nails a shiny appearance and provides excellent corrosion resistance, particularly in harsh environments. This ensures the Roofing Nails have a long lifespan and resist rusting.

- High Lightning Resistance: The Cr plating not only enhances the aesthetic but also improves the nail’s lightning resistance, making it suitable for projects that require high electrical safety standards.

- Conical Design Under the Head: The conical angle below the nail head is designed to withstand strong hammering forces without deformation or breakage.

Uses of Roofing Nails

Roofing Nails have numerous applications in various construction and production fields, especially in environments requiring waterproofing and excellent fastening capabilities:

- Waterproofing Wooden Boats: These nails are used to fasten waterproof materials like composite resin onto the outer hulls of wooden boats, enhancing durability and water resistance.

- Fastening Mesh Layers: In construction, Roofing Nails help securely fasten mesh layers, ensuring structural integrity and durability.

- Applications in Composite Plastics: These nails are also widely used in the fabrication of composite plastic products, ensuring the materials’ rigidity and strength.

Packaging Specifications and Quality Standards

United Nail’s Roofing Nails are not only superior in design but are also produced under strict quality control processes, meeting international standards. The products are packed in 5kg PE plastic bags, then into 50kg KP bags, making them easy to transport and use.

Roofing Nails – The Smart Choice for the Construction Industry

Using Roofing Nails in construction offers many benefits, not only in terms of stability but also in saving costs and time. With corrosion resistance and high durability, these nails are the perfect solution for projects that require stability and long-lasting performance.

Specifically, United Nail’s Roofing Nails are designed to work on various surfaces such as wood, metal, and composite plastic, ensuring optimal construction performance. The nails also withstand harsh weather conditions and chemicals in the construction environment, extending the life of the project.

Why Choose United Nail’s Roofing Nails?

United Nail is a leading brand in the production and supply of Roofing Nails. The company’s products are manufactured with cutting-edge Taiwanese technology, and its staff is trained under the JICA 5S program (Japan International Cooperation Agency), ensuring production processes are always up to standard and delivering high-quality products.

Moreover, United Nail’s Roofing Nails undergo quality verification by the Standards Measurement and Quality Center, ensuring that the products always meet high quality and reliability standards in international markets.

Conclusion

Roofing Nails, also known as large-head nails, are the optimal solution for modern construction projects. With smart design, superior load-bearing capacity, and corrosion resistance, this product has established its position in the construction industry.

If you’re looking for a product that meets the most stringent standards and has a wide range of applications,