In the construction industry, ensuring the durability and stability of reinforced concrete structures is critical. Among the materials that contribute to this stability, the 1mm binding wire, plays an essential role. At United Nail, the production of 1mm binding wire is carried out using advanced technology to ensure superior quality, reliability, and long-lasting performance. This article will provide an in-depth look at United Nail’s production process for this essential product and explain why it consistently meets the high demands of both local and international markets.

MỤC LỤC BÀI VIẾT

1. The Importance of 1mm Binding Wire in Construction Projects

1mm binding wire is a key material used in the construction industry, particularly in the reinforcement of concrete structures. It plays an integral role in ensuring the strength and stability of reinforced concrete, ensuring that the steel bars (rebars) used in construction are securely held in place. The wire is essential in ensuring that concrete structures can bear significant loads without risk of failure.

In addition to its use in construction, 1mm binding wire is also applied in various other industries, such as scaffolding, wire mesh for industrial applications, and even in agriculture. The flexibility, strength, and durability of the wire make it ideal for a wide range of uses beyond construction.

2. United Nail’s Commitment to High-Quality 1mm Binding Wire

For over 24 years, United Nail has been a trusted leader in manufacturing binding wire, providing high-quality materials for construction projects. With our focus on quality and customer satisfaction, we’ve developed a strict production process to ensure that our 1mm binding wire meets the highest international standards.

Our manufacturing process integrates the latest technology to create a product that’s not only durable but also highly efficient for construction purposes. Let’s delve into the steps involved in producing United Nail’s 1mm binding wire and how each step contributes to the superior quality of the final product.

3. Step-by-Step Production Process of United Nail’s 1mm Binding Wire

3.1. Selecting High-Quality Raw Materials

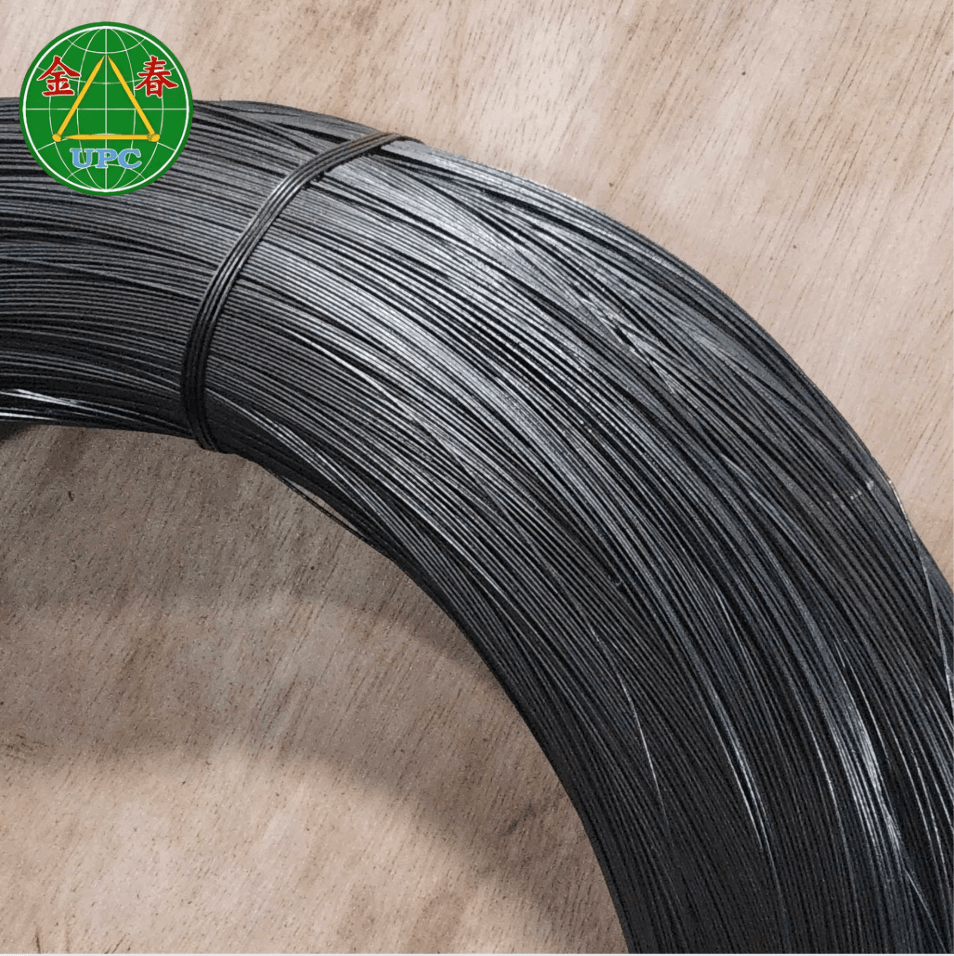

The first step in the production of 1mm binding wire is the selection of raw materials. At United Nail, we only use high-quality carbon steel for our binding wire. Carbon steel is known for its excellent tensile strength, which ensures that the final product can withstand significant pressure and stress without breaking.

Our steel is sourced from reliable suppliers and meets international standards, ensuring that the binding wire produced is both strong and durable. This careful selection of materials is key to producing wire that can perform well under demanding conditions, whether on construction sites or in other industrial applications.

3.2. The Wire Drawing Process

After the raw steel is selected, it undergoes the wire drawing process. This process involves drawing the steel through a series of progressively smaller dies to reduce its diameter to the desired 1mm size. The wire is drawn carefully to maintain its integrity, ensuring it remains strong and flexible.

The wire drawing process also enhances the wire’s surface finish, ensuring smoothness and reducing any potential weaknesses that could cause breakage. This precision in the wire drawing process is essential for creating a product that can be easily handled and manipulated during installation.

3.3. Quality Control: Ensuring Consistency and Performance

At United Nail, we prioritize quality control at every stage of the production process. Each batch of binding wire is thoroughly inspected to ensure that it meets our strict quality standards. Our quality control team checks for several factors, including tensile strength, flexibility, and corrosion resistance.

Before the binding wire leaves the factory, it undergoes rigorous testing to ensure that it meets all technical specifications. If any issues are detected, the product is either reprocessed or discarded, ensuring that only the highest quality wire reaches our customers.

3.4. Packaging and Shipping: Prepared for Delivery

Once the wire has passed quality checks, it is packaged carefully to prevent any damage during transportation. The wire is typically wound into coils, with each coil weighing between 25 to 50 kilograms. These coils are then securely packaged for shipping, ensuring that they arrive at the construction site in optimal condition.

United Nail offers flexible delivery options, including same-day delivery for urgent orders, ensuring that our customers’ construction projects stay on schedule without delays.

4. The Benefits of Choosing United Nail’s 1mm Binding Wire

United Nail’s 1mm binding wire offers several benefits that make it the preferred choice for construction professionals:

Superior Quality: Our binding wire is made from high-quality carbon steel, providing exceptional tensile strength and resistance to breakage. It is designed to withstand the demanding conditions of construction work, ensuring reliable performance.

Reliable Delivery: United Nail offers fast and efficient delivery services, ensuring that our customers have access to the materials they need when they need them. Whether you need a large quantity of wire or a small batch, we can meet your needs in a timely manner.

Professional Support: Our experienced team is available to assist customers with any inquiries or technical support. Whether you need advice on the right product for your project or help with product specifications, we are here to help.

5. Why United Nail is the Trusted Choice for 1mm Binding Wire

Choosing United Nail as your supplier for 1mm binding wire guarantees you a product that is crafted with precision, durability, and quality in mind. With over 24 years of experience in manufacturing high-quality materials for construction, we understand the needs of the industry and the importance of using reliable materials to ensure the success of your projects.

Our strict quality control procedures, advanced production techniques, and commitment to customer satisfaction make United Nail the go-to choice for binding wire that can stand the test of time.

6. Get in Touch with United Nail for Your 1mm Binding Wire Needs

If you are looking for high-quality 1mm binding wire for your next construction project, United Nail is here to help. With over two decades of experience in manufacturing binding wire and other construction materials, we offer products that meet the highest standards of quality and reliability.

Contact us today for more information about our 1mm binding wire or to request a quote. Our team is ready to assist you with your material needs and ensure that your construction projects run smoothly.

Conclusion

United Nail’s 1mm binding wire is a trusted material that has been a reliable choice for construction professionals for over 24 years. With a rigorous production process, top-quality raw materials, and a commitment to customer satisfaction, our binding wire is designed to deliver exceptional performance and durability for all types of construction projects.

Contact information

UNITED NAIL PRODUCTS CO., LTD

Specializing in manufacturing high quality industrial nails and tie wire

Address: 16A8, Tra Noc Industrial Zone 1, Tra Noc Ward, Binh Thuy District, Can Tho City, VietNam

Phone: (+84) 986 831838; (+84) 292 242165

Email: sales5@unitednail.com

Thank you for reading this article, hope the information is useful to you.