In modern construction, small materials often play a big role in structural performance and jobsite efficiency. One such material is wire used for binding and fastening, commonly referred to as tie wire or rebar wire. Although these terms are sometimes used interchangeably, they are not always the same. Understanding the differences between tie wire and rebar wire, as well as their specific applications, is essential for contractors, engineers, and buyers sourcing materials for construction projects.

This article explains what tie wire and rebar wire are, how they differ in material and performance, and how to choose the right type for your application.

MỤC LỤC BÀI VIẾT

What Is Tie Wire?

Tie wire is a general term used to describe soft steel wire designed for binding, fastening, or securing materials together. It is widely used in construction, packaging, agriculture, and industrial applications.

Common Characteristics of Tie Wire

Made from low-carbon steel

Often annealed to improve softness and flexibility

Available in different diameters (commonly 0.8 mm to 1.6 mm)

Supplied in coils, cut lengths, or bundled form

Can be black annealed, galvanized, or PVC coated

Because of its flexibility, tie wire is easy to twist and bend without breaking, making it suitable for many non-structural binding tasks.

Typical Applications of Tie Wire

Securing light construction materials

Bundling steel bars or pipes for transport

Temporary fastening on construction sites

Packaging and industrial binding

Agricultural fencing and tying

In short, tie wire is a multi-purpose product used across various industries, not limited to reinforced concrete work.

What Is Rebar Tie Wire?

Rebar wire is a specialized type of tie wire specifically designed for tying reinforcing steel bars (rebar) in concrete construction. Its main purpose is to hold rebar in the correct position before and during concrete pouring.

Key Characteristics of Rebar Wire

Typically black annealed tie wire

Very soft and flexible for fast manual tying

High resistance to snapping during twisting

Optimized diameter for rebar work (usually 1.0 mm–1.3 mm)

Compatible with manual tying and automatic tying tools

Rebar wire does not carry structural loads. Instead, it ensures rebar spacing and alignment remain correct until the concrete sets.

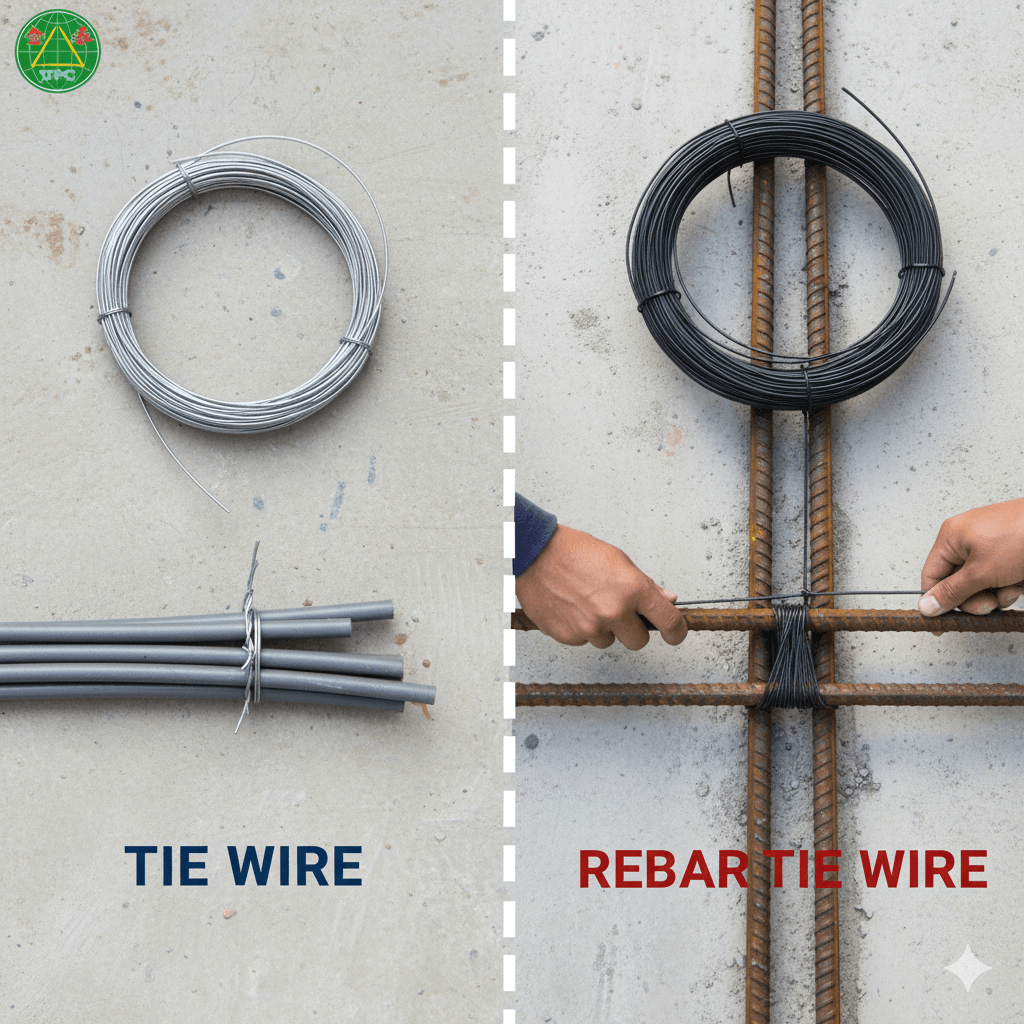

Tie Wire vs Rebar Tie Wire: Core Differences

Although rebar wire is technically a type of tie wire, there are important differences in design, performance, and application.

1. Purpose and Application

General-purpose binding for multiple industries

Rebar wire: Dedicated to reinforcing steel in concrete structures

Rebar wire is engineered specifically for construction accuracy, while standard wire offers broader usability.

2. Material Treatment

May be annealed, galvanized, or coated

Rebar wire: Almost always black annealed

Black annealed wire is heat-treated to remove internal stress, resulting in maximum softness, which is critical for fast and repeated rebar tying.

3. Flexibility and Tensile Behavior

- Balanced flexibility and strength

- Rebar wire: Extra soft, designed to twist easily without breaking

On busy construction sites, workers may tie thousands of joints per day. Rebar wire minimizes hand fatigue and reduces wire breakage.

4. Diameter and Size Range

- Wide size range depending on application

- Rebar wire: Standardized sizes optimized for rebar (16–18 gauge equivalent)

Using the wrong diameter can slow down work or cause unstable rebar positioning.

5. Compatibility With Tying Tools

- Often used manually

Rebar wire: Designed for both manual tying and automatic rebar tying machines

Many modern construction projects rely on automatic tying tools, which require consistent wire diameter and surface finish.

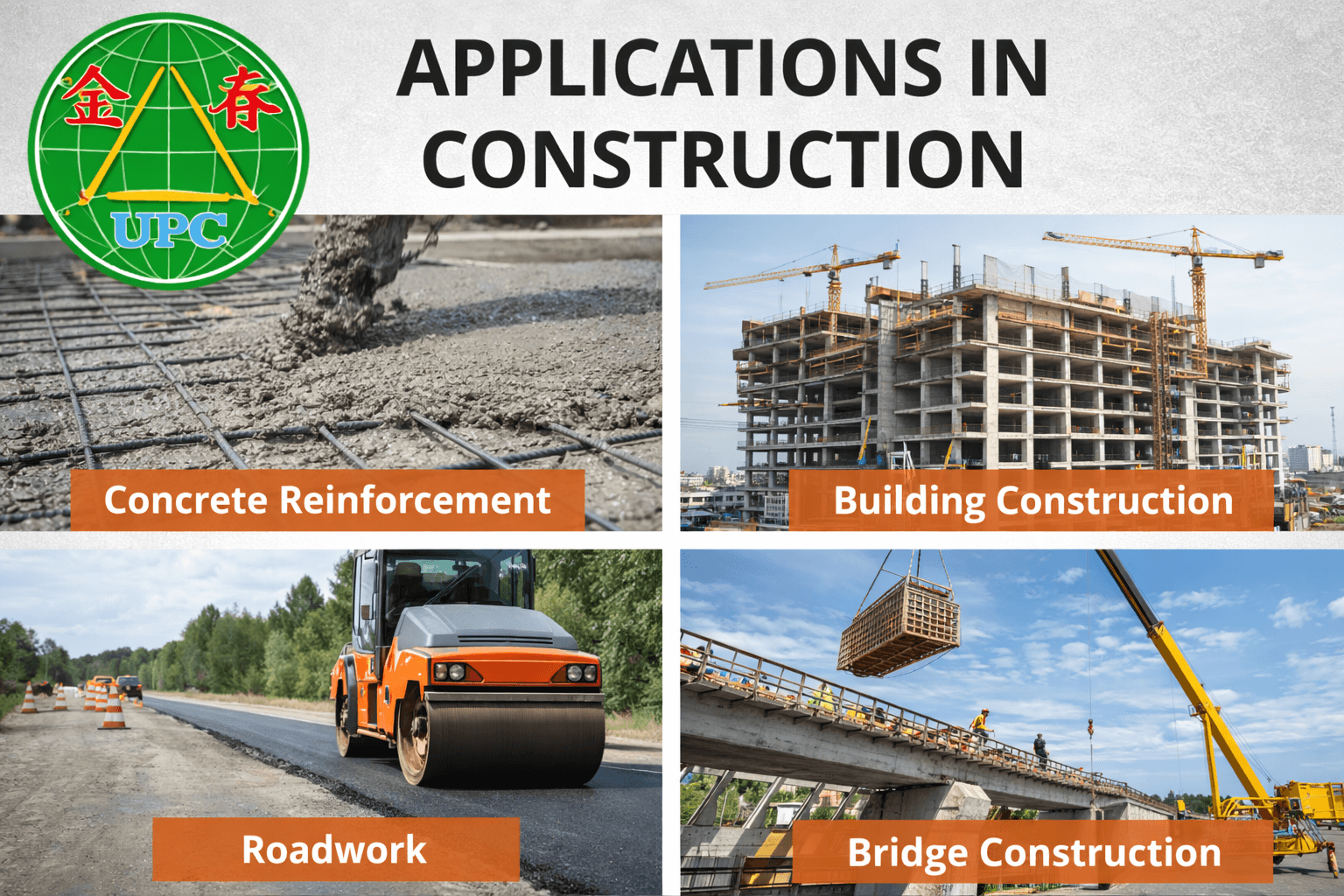

Applications in Construction

When to Use Tie Wire

General wire is suitable when:

Binding materials for storage or transport

Temporary fastening not related to structural alignment

Light-duty construction tasks

Non-critical positioning work

Tie wire offers versatility and cost efficiency for non-specialized tasks.

When to Use Rebar Tie Wire

Rebar wire should be used when:

Tying reinforcing steel in slabs, beams, and columns

Maintaining precise rebar spacing

Working with dense reinforcement layouts

Using rebar tying machines

In reinforced concrete construction, using proper rebar wire improves efficiency, safety, and consistency.

Why Black Annealed Tie Wire Is Preferred for Rebar

Black annealed tie wire dominates rebar applications for several reasons:

Superior Softness

Annealing reduces hardness, making the wire easy to twist by hand.Reduced Breakage

Soft wire resists snapping during repeated twisting.Faster Installation

Workers can tie joints more quickly, improving productivity.Cost Efficiency

Compared to coated wires, black annealed tie wire offers an excellent balance of performance and price.

Because the wire is embedded in concrete, corrosion resistance is less critical than flexibility, making black annealed wire the ideal choice.

Common Specifications for Rebar Tie Wire

When sourcing rebar wire from a manufacturer or supplier, buyers typically look for the following specifications:

Material: Low-carbon steel (Q195 / SAE 1006–1008)

Surface finish: Black annealed

Diameter: 0.8 mm – 1.3 mm (custom sizes available)

Tensile strength: Optimized for flexibility, not maximum strength

Packaging: Coils, spools, or cut lengths

Compliance: ASTM, JIS, or equivalent standards (if required)

Clear specifications help ensure compatibility with jobsite requirements and tying tools.

Choosing Between Tie Wire and Rebar Tie Wire

To choose the right product, consider these questions:

Is the wire used for rebar positioning?

If yes, rebar wire is the correct choice.Is flexibility more important than strength?

Rebar wire offers superior softness.Will you use automatic tying tools?

Use rebar wire with consistent diameter and finish.Is the application temporary or non-structural?

Standard wire may be sufficient.

Selecting the right wire reduces labor costs and prevents on-site issues.

Buying Tips for Contractors and Importers

When sourcing from a tie wire or rebar wire manufacturer, buyers should evaluate:

Consistency of wire diameter

Annealing quality and softness

Coil weight accuracy

Packaging suitability for export

Supplier production capacity and lead time

Reliable suppliers provide technical data sheets, samples, and stable quality, which are essential for large construction projects and export markets.

Conclusion

While tie wire and rebar wire are closely related, they serve different purposes in construction and industry. Tie wire is a versatile binding solution used across multiple sectors, whereas rebar wire—most commonly black annealed wire—is specifically engineered for reinforcing steel work.

Understanding the key differences in application, flexibility, material treatment, and specifications allows contractors and buyers to select the right product, improve jobsite efficiency, and ensure construction accuracy.

For reinforced concrete projects, choosing proper rebar wire is a small decision that delivers big results in productivity, safety, and overall build quality.

Contact information

UNITED NAIL PRODUCTS CO., LTD

Address: 16A8, Tra Noc Industrial Zone 1, Tra Noc Ward, Binh Thuy District, Can Tho City, VietNam

Phone: (+84) 986 831838; (+84) 292 242165

Email: sales5@unitednail.com

Thank you for reading this article, hope the information is useful to you