The Secret to Choosing the Right Steel Nail for Every Application

Selecting the proper nail for any construction or woodworking project may seem simple, but with various types, materials, and sizes available, it’s important to make informed choices. Nails play a vital role in building sturdy structures, and steel nails in particular offer the strength and durability needed for many applications. United Nail Product Co., Ltd., at Viet Nam a trusted name in nail manufacturing, provides a wide range of high-quality nails suitable for every job.

This guide will walk you through everything you need to know about picking the right nail, from understanding the different types to matching them with the appropriate application.

MỤC LỤC BÀI VIẾT

Why Steel Nails Matter

When it comes to structural integrity and safety, nails are key. For projects like framing, decking, and roofing, a reliable, strong nail is critical. Steel nails, in particular, stand out because they are less likely to bend or break under pressure. Their versatility and resistance to wear make them ideal for both residential and commercial construction.

However, to maximize their potential, it’s crucial to select the correct type for your specific job. There’s a variety to choose from, and understanding their differences will help ensure a solid outcome.

Types of Steel Nails

Different types of nails are designed to perform specific functions, and steel versions are no exception. Below are some of the most commonly used types and their typical applications:

- Common Nails

- One of the most widely used nail types, especially in structural work. They are perfect for heavy-duty tasks like framing due to their thick shank and wide head, offering a strong hold.

- Finishing Nails

- These nails are smaller and have a small head, making them ideal for tasks where the nail will be hidden, like molding or trim work. They are usually driven slightly below the surface and can be concealed with putty.

- Roofing Nails

- Roofing nails have a large, flat head to hold down roofing materials like shingles or sheet metal securely. The head prevents the material from tearing, ensuring the roof remains intact even in harsh weather. Steel nails are particularly popular for this application due to their rust resistance when galvanized.

By understanding these different types of steel nails, you can match the right product to your project’s needs, ensuring better performance and longevity.

Choosing the Right Nail Length and Diameter

One critical aspect of nail selection is choosing the right length and diameter. The size of the nail you use affects its holding power and the overall strength of the structure. Here’s a quick guide to nail sizing:

- Length: As a general rule, the nail should be at least three times the thickness of the material being nailed. For example, if you’re attaching a 1-inch thick piece of wood, you’ll want to use a 3-inch nail.

- Diameter: Thicker nails (larger diameters) provide more holding power but may be harder to drive into the material. For softer woods, you can use thinner nails, but for harder materials or heavy-duty applications, thicker nails are better.

Matching the size of the nail to the material and the load it will bear is essential for ensuring that the structure remains stable over time.

Material Considerations: Why Steel Nails Are Superior

When choosing nails, the material they are made of is just as important as their size and type. Steel nails are a top choice for many construction projects due to their strength, durability, and resistance to corrosion when properly treated.

Steel nails, especially galvanized or stainless steel versions, are perfect for outdoor or moisture-prone environments because they don’t rust as easily as other materials like iron. This makes them ideal for projects like roofing, decking, or exterior siding, where long-term exposure to the elements is a concern.

In addition, steel nails offer the tensile strength needed to hold structures together under stress, making them suitable for high-load applications such as framing, flooring, and masonry.

The Importance of Corrosion Resistance

For projects that will be exposed to moisture or harsh conditions, corrosion resistance is a crucial factor. Galvanized steel nails are coated with a layer of zinc, which helps protect the underlying steel from rust and corrosion. This is particularly important for outdoor applications, where untreated steel nails would quickly degrade, leading to structural failure.

On the other hand, stainless steel nails are made from an alloy that resists rust and corrosion naturally. These are a bit more expensive than galvanized nails but are worth the investment for projects where long-term durability is key, such as marine construction or exterior finishing.

United Nail Co., Ltd. offers a wide range of galvanized and stainless steel nails, ensuring that no matter the environment, their products provide the necessary protection against rust and wear.

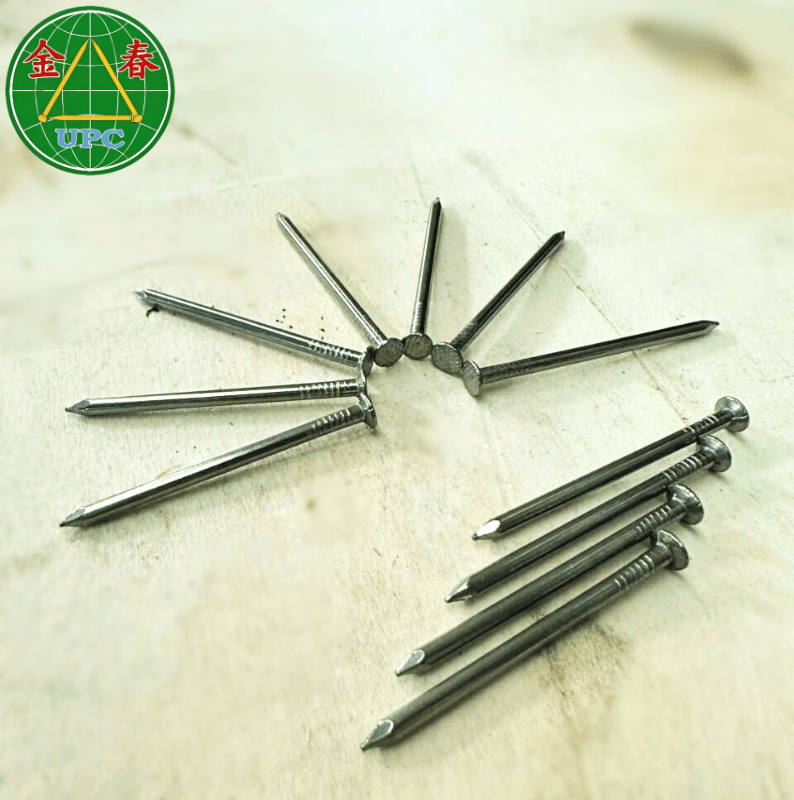

Photo 3: Many different types of steel nails with many applications in life

Application-Specific Nail Choices

Every project has unique requirements, and selecting the right nail can greatly improve the outcome. Here are a few key applications and the recommended types of steel nails:

- Framing: For heavy framing work, you’ll want to use common or box nails made of steel for strength. These nails provide the holding power needed to support large loads and maintain structural integrity.

- Decking: Decks are exposed to the elements, so corrosion resistance is essential. Use galvanized or stainless steel nails, particularly spiral shank nails, to ensure they stay secure and resist rust over time.

- Flooring: Flooring requires nails that can grip the wood without causing it to split or come loose with heavy foot traffic. Ring shank or screw shank steel nails are ideal for this application.

- Roofing: Roofing nails need to withstand both the weight of the materials and the stresses caused by wind and weather. Use large-headed, galvanized steel nails for this job to ensure they don’t rust or pull out over time.

- Finish Carpentry: When working on finish carpentry, such as installing trim or molding, use finishing nails. These are smaller in size and have a slender head that can be easily concealed, providing a clean and professional look.

- Masonry Work: For attaching wood or other materials to concrete or stone, choose masonry nails. Steel masonry nails are specifically hardened to resist bending or breaking when driven into hard surfaces.

United Nail Product Co., Ltd. — A Leader in Quality Steel Nails

With a wealth of experience in the nail industry, United Nail Product Co., Ltd. has earned a reputation for producing top-quality steel nails that meet the demands of various industries. Their commitment to quality is reflected in their use of high-grade steel and rigorous testing processes, ensuring that every nail performs reliably.

United Nail offers a diverse range of steel nails, from common nails to specialty nails for specific applications. Their products are designed to meet international standards, and the company continually invests in innovation to enhance the durability and efficiency of their nails.

Tips for Driving Steel Nails Effectively

Even the best steel nail will only perform well if it’s driven correctly. Here are a few tips to ensure proper installation:

- Use the Right Tool: While a hammer is suitable for most small-scale jobs, larger nails or projects might require a nail gun for efficient installation.

- Pre-Drill Holes for Hardwoods: When working with hardwoods or dense materials, pre-drilling small holes can help prevent the nails from bending or causing the wood to split.

- Drive the Nail at the Correct Angle: For most applications, nails should be driven in at a 90-degree angle to ensure maximum holding power. In some cases, driving them at a slight angle can add extra strength, especially in framing work.

- Avoid Overdriving: Be cautious not to overdrive the nail, especially when using a nail gun, as this can weaken the material around the nail and reduce its holding strength.

Conclusion

Selecting the right steel nail for your application involves understanding the type, size, and material best suited for the job. By considering factors like load requirements, exposure to the elements, and the materials you’re working with, you can make an informed choice that ensures the longevity and stability of your project.

United Nail Product Co., Ltd. offers a wide selection of high-quality steel nails that cater to every need, from construction to fine finishing. Their commitment to durability and performance guarantees that whether you’re building a deck, installing trim, or framing a house, their products will get the job done right.

In any project, nails may be small, but they are vital to the strength and success of your work. By selecting the right steel nails, you ensure that your structures remain secure and your craftsmanship stands the test of time.