In recent years, the production of coil nails has seen significant innovations driven by technological advancements, sustainability efforts, and the demand for high-quality, durable products. These trends are reshaping the industry, making coil nails more efficient, environmentally friendly, and versatile. Let’s explore the latest developments in coil nails production that are transforming the construction and manufacturing sectors.

MỤC LỤC BÀI VIẾT

1. Automation

- The adoption of automation technology is revolutionizing the way coil nails are produced. From robotic systems to advanced machinery, automation is significantly improving production speed, consistency, and precision.

Automated Production Lines:

- Robotic arms and automated systems are now commonly used to handle repetitive tasks such as forming, cutting, and packaging coil nails. This reduces human error, increases output, and allows for continuous production without breaks.

- Automatic coil winding machines enable manufacturers to produce coil nails in bulk, efficiently forming them into coils while ensuring uniformity and high quality.

Benefits:

- Increased productivity with fewer interruptions.

- Reduced labor costs and enhanced safety.

- Consistent quality and precision in every nail.

2. Advanced Materials and New Technologies

As the demand for high-performance coil nails grows, manufacturers are exploring new materials and innovative technologies to improve the durability and performance of their products.

High-Quality Steel :

- Carbon steel is increasingly being used in the production of coil nails, offering superior resistance to rust, corrosion, and environmental wear. This is particularly useful for applications in coastal areas or regions with high humidity.

- Carbon steel is also gaining popularity due to their enhanced strength and resistance to impact, ensuring coil nails perform well under tough conditions.

Coating Technologies:

- Zinc coatings remain common, providing basic protection against corrosion. However, newer dual-coating technologies have emerged, offering enhanced corrosion resistance and durability in harsher environments.

- Some manufacturers are experimenting with eco-friendly coatings that offer the same level of protection but with less environmental impact.

Benefits:

- Superior durability, ideal for construction projects exposed to harsh elements.

- Longer lifespan, reducing the frequency of replacement and maintenance.

- Improved performance for demanding applications like roofing, framing, and outdoor structures.

3. Sustainability in Coil Nails Production

Sustainability is becoming a priority in many industries, and the coil nails sector is no exception. As the world moves towards more sustainable manufacturing practices, companies are adopting eco-friendly methods in the production of coil nails.

Energy-Efficient Production:

- Modern manufacturing plants are integrating renewable energy sources, such as solar power or wind energy, to reduce their carbon footprint. This not only cuts down on the environmental impact but also helps manufacturers save on energy costs.

- Energy-efficient machinery is replacing older equipment, reducing electricity consumption while maintaining high production capacity.

Recycling and Reuse:

- Many manufacturers are moving towards using recycled steel and other materials in the production of coil nails. This helps lower the demand for raw materials and reduces the amount of scrap metal in landfills.

- Zero-waste manufacturing processes are being developed, where excess material is repurposed or recycled, creating a more circular production system.

Benefits:

- Reduced environmental impact, contributing to a greener planet.

- Lower production costs by using recycled materials and energy-efficient processes.

- Compliance with global sustainability standards, which is increasingly important to consumers and businesses alike.

4. Enhanced Nail Head Designs and Functionality

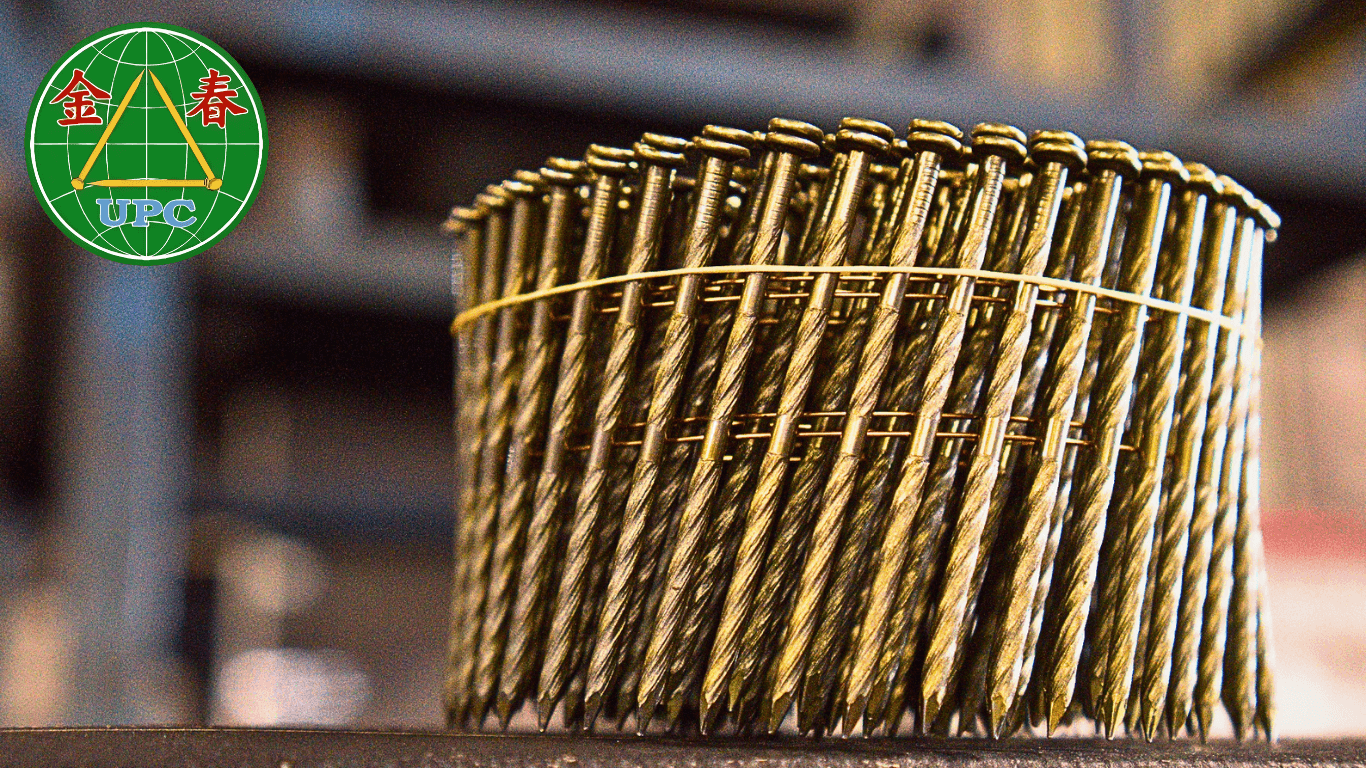

Another exciting trend in coil nails production is the improvement of nail head designs to enhance their functionality in various applications.

Innovative Nail Head Designs:

- Ring-shank are becoming increasingly popular for their superior holding power. The ringed head design allows the nail to grip wood or other materials more securely, making them ideal for roofing, decking, and framing applications.

- Flat-head coil nails are still widely used for general construction, offering easy insertion and smooth, flush finishes.

Multi-Functional:

- Manufacturers are also producing multi-purpose coil nails that can be used in different materials such as wood, metal, and concrete. These nails are treated with special coatings to ensure they perform well in diverse environments.

- Some coil nails are designed to resist corrosion and UV degradation, making them suitable for outdoor use in various weather conditions.

Benefits:

- Better performance in demanding applications, such as heavy-duty construction or outdoor projects.

- Versatility, allowing contractors to use a single type of nail for multiple tasks.

- Improved safety and durability, reducing the likelihood of nail failure.

5. Enhanced Quality Control

The push for higher-quality products is also influencing the coil nails industry, leading to more rigorous quality control measures and advanced testing technologies.

Automated Quality Control:

- Today, many manufacturers use laser scanning and automated testing systems to inspect coil nails during production. These systems check for defects, dimensional accuracy, and surface quality, ensuring only the highest-quality nails reach the market.

- Digital inspection systems also allow for real-time monitoring of production, identifying potential issues before they become major problems.

Benefits:

- Consistent quality in every batch of coil nails.

- Reduced product defects, ensuring a more reliable end product.

- Faster identification of production issues, minimizing downtime and waste.

6. Smart and High-Tech Nails

Looking ahead, there’s an exciting prospect for smart coil nails. With the rise of Internet of Things (IoT) technology, manufacturers are exploring ways to embed sensors in coil nails, allowing real-time tracking of their usage and performance.

Smart Coil Nails:

- These “smart” nails could collect data on factors like temperature, pressure, or stress levels during construction, providing valuable insights into the integrity of a building structure over time.

- This technology would allow construction professionals to monitor the condition of their buildings or installations remotely and make timely interventions when necessary.

Benefits:

- Real-time data collection that can improve construction safety and longevity.

- Enhanced building maintenance, providing data for predictive maintenance and reducing unexpected repairs.

Conclusion

The production of coil nails is undergoing a significant transformation, driven by technological advancements, the need for sustainability, and growing demands for high-performance materials. As automation, material science, and quality control processes continue to evolve, coil nails are becoming more durable, versatile, and environmentally friendly, meeting the needs of modern construction and manufacturing industries. With these ongoing innovations, coil nails will continue to be an essential tool in building the structures of tomorrow.

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production

Thank you for taking the time to read this article. We hope the information proves helpful to you.