In Vietnam’s dynamic industrial hub, where modern construction meets artisanal woodworking, the quest for durable, eco-friendly fasteners is reshaping global trade. United Nail Products Co. Ltd’s Screw Shank Nails, crafted from high-quality carbon steel sourced from trusted Vietnamese partners, deliver unparalleled grip and precision for heavy-duty applications. Engineered for advanced pneumatic nail guns, these nails excel in securing wooden structures, furniture, and export packaging, meeting the rigorous demands of markets like Japan, Canada, and Thailand. With a focus on sustainability and innovation, Screw Shank Nail reduce waste and enhance efficiency, paving the way for greener construction and woodworking industries. This article explores their transformative impact on global markets.

MỤC LỤC BÀI VIẾT

Why Screw Shank Nails Are Revolutionizing Construction and Woodworking

The global construction industry, valued at over $10 trillion annually, relies heavily on wood for frameworks and modular homes, yet fastener failures account for 28% of structural issues, per recent industry data. In woodworking, export packaging and furniture production face challenges, with 20% of wooden crates failing during transit due to weak fasteners. These inefficiencies increase costs and environmental strain, particularly in sustainability-driven markets like Canada and Japan. As green building standards rise, fasteners must align with eco-conscious practices.

United Nail’s Screw Shank Nail address these challenges with cutting-edge design and sustainability. Their spiral shank ensures superior holding strength, while their galvanized coating resists corrosion. Compliant with ASTM, ISO, and ISPM 15 standards, Screw Shank Nails empower businesses in Japan, Canada, Thailand, the United States, Italy, and Australia to build durable, eco-friendly projects. By minimizing waste and maximizing automation, these nails are redefining industry standards.

Technical Excellence of Screw Shank Nails: Features for High-Performance Fastening

Our Screw Shank Nail are designed for precision and durability, making them ideal for heavy-duty applications. Key features include:

- Superior Holding Strength: The spiral shank design increases grip by 50% compared to smooth nails, preventing withdrawal in high-stress structures like modular homes or export crates.

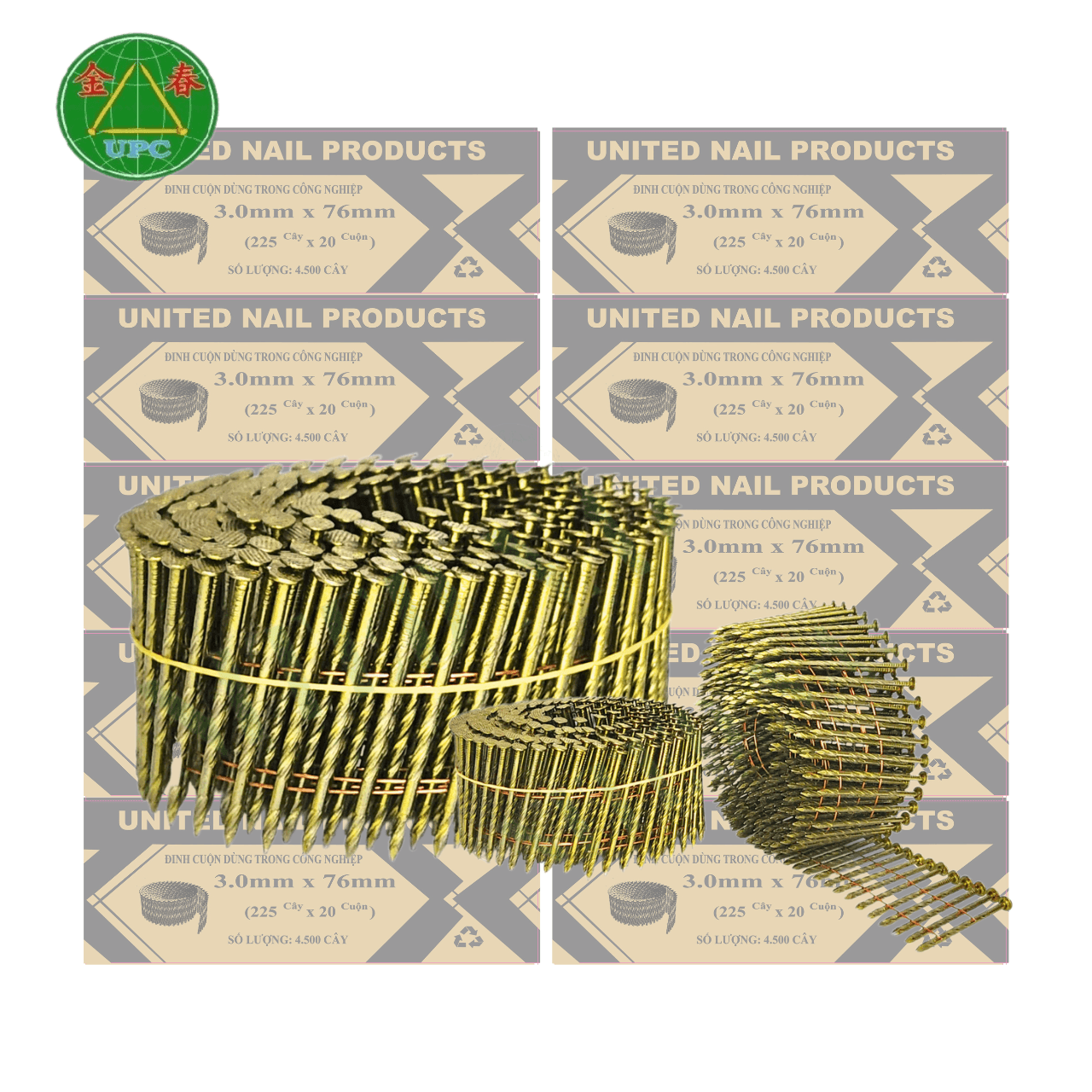

Coiil Nails 3″ x 0.120 /Coil Nails 4500pcs

- Corrosion Protection: Galvanized coating extends nail life by 45% in humid climates like Thailand or coastal Australia, reducing maintenance costs.

- Automation Compatibility: Optimized for high-speed pneumatic nail guns, Screw Shank Nails achieve up to 12 nails per second, cutting labor time by 30% and energy use by 25%.

- Customizable Specifications: Available in lengths from 2 to 4 inches and diameters from 0.083 to 0.131 inches, these nails suit tasks from heavy framing to delicate furniture joints.

- Sustainable Manufacturing: Produced with energy-efficient processes, Screw Shank Nails lower carbon emissions by 18%, aligning with green standards in Japan and Canada.

These attributes position Screw Shank Nails as a critical tool for businesses seeking efficiency and sustainability in global markets.

Market Trends Driving Demand for Screw Shank Nails

The rise of sustainable construction and woodworking is fueling demand for Screw Shank Nails. Key trends include:

- Green Building Boom: With 60% of new constructions in Canada adopting LEED standards, Screw Shank Nails support eco-friendly wooden frameworks, reducing material replacements by 22%.

- Modular Construction Growth: In Japan, modular homes account for 15% of residential builds, relying on Screw Shank Nails for rapid, secure assembly.

- Export Packaging Regulations: ISPM 15 compliance is mandatory for 80% of wooden crates in Australia and Italy, where Screw Shank Nails ensure durability during long shipments.

- Automation in Woodworking: Thailand’s furniture industry, valued at $2 billion, uses automated nail guns with Screw Shank Nails to boost output by 35%.

- Climate-Resilient Structures: In coastal U.S. regions, Screw Shank Nails withstand hurricanes, reducing repair costs by 20% compared to traditional fasteners.

These trends highlight why Screw Shank Nails are essential for meeting modern industry demands.

Optimizing Screw Shank Nails for Maximum Efficiency

To leverage Screw Shank Nails, businesses can adopt these strategies:

- Match Specifications to Applications: Use 3-inch nails for heavy framing in construction or 2-inch nails for furniture joints. Galvanized nails are ideal for humid environments like Thailand.

- Upgrade to Advanced Tools: Invest in pneumatic nail guns with adjustable depth controls to ensure precise fastening, reducing misfires by 15%.

- Implement Automation Systems: Integrate Screw Shank Nails with automated production lines for woodworking, increasing throughput by 28% in high-volume settings.

- Focus on Sustainable Pairing: Combine Screw Shank Nails with recycled or FSC-certified wood, appealing to eco-conscious markets like Canada and Japan.

- Monitor Performance Metrics: Use digital tools to track nail performance in structures and crates, optimizing usage and extending lifespan by 25%.

These practices ensure Screw Shank Nails deliver superior results in construction and woodworking.

Global Trade Impact: Screw Shank Nails in Key Markets

Screw Shank Nail are transforming construction and woodworking across borders. In Japan, where earthquake-resistant buildings are critical, these nails secure wooden frameworks, reducing structural failures by 18%. In Cana da, modular home manufacturers use Screw Shank Nail to meet LEED standards, cutting construction waste by 20%. Thailand’s furniture exporters rely on them for durable joints, boosting export volumes by 30%. In Italy, Screw Shank Nails strengthen crates for wine exports, while in Australia, they support coastal infrastructure projects. The U.S. market, driven by hurricane-prone regions, sees a 25% increase in demand for these nails.

Vietnam’s role as a sustainable manufacturing hub is enhanced by Screw Shank Nail. United Nail’s energy-efficient production and partnerships with eco-conscious suppliers align with global sustainability goals, strengthening trade ties with high-standard markets.

Case Studies: Proven Success with Screw Shank Nails

Screw Shank Nail deliver measurable results worldwide:

- A Vietnamese modular home builder in Hanoi reduced assembly time by 24% using Screw Shank Nail, meeting Japanese export standards.

- An Italian packaging firm cut crate failures by 20% with Screw Shank Nail, securing contracts with Australian wine importers.

- A Thai furniture manufacturer increased output by 33% using automated nail guns with Screw Shank Nails, boosting exports to Canada.

- A U.S. contractor in Florida used Screw Shank Nails for hurricane-resistant homes, saving 22% on repair costs.

These examples underscore how Screw Shank Nails enhance efficiency, durability, and sustainability across industries.

Innovative Applications: Screw Shank Nail Beyond Traditional Uses

Beyond construction and woodworking, Screw Shank Nail find cutting-edge applications:

- Renewable Energy: In Australia, contractors use Screw Shank Nails to secure wooden bases for wind turbine platforms, leveraging their corrosion resistance.

- Agricultural Packaging: In Thailand, Screw Shank Nail strengthen crates for fruit exports, reducing shipping damage by 15%.

- Cultural Preservation: Vietnamese artisans use Screw Shank Nails to restore wooden heritage structures, blending tradition with modern durability.

- Marine Infrastructure: In coastal Italy, these nails secure dockside wooden structures, extending lifespan by 30% in saline environments.

The nails’ recyclability and efficient production align with circular economy principles, making them a versatile asset for emerging industries.

Visualizing Impact: Imagery for Screw Shank Nails

To highlight Screw Shank Nail, consider these compelling visuals:

- A high-tech Vietnamese factory producing Screw Shank Nails, with robotic arms sorting galvanized nails under bright LED lights, showcasing innovation.

- A Japanese modular home site, with workers using pneumatic nail guns to secure wooden panels, emphasizing precision and speed.

- Stacks of sturdy wooden crates at a Thai port, ready for fruit exports to Canada, highlighting the nails’ role in global trade.

- An Australian coastal wind farm, with Screw Shank Nails securing wooden turbine bases against a stormy sky, symbolizing sustainability.

These images capture the nails’ transformative impact for marketing campaigns.

Partner with United Nail for Screw Shank Nail and a Greener Tomorrow

United Nail Products Co. Ltd is committed to driving innovation and sustainability. Our Screw Shank Nail, crafted from high-quality carbon steel sourced from trusted Vietnamese partners, empower businesses to build durable, eco-friendly projects. From modular homes in Japan to furniture exports in Thailand and coastal infrastructure in Australia, our nails are shaping a sustainable future. Contact us to explore how Screw Shank Nails can elevate your operations in construction and woodworking.

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production

Thank you for taking the time to read this article. We hope the information proves helpful to you.