Wire nails are an indispensable tool in many industrial fields. With its versatility and high quality, this product has become the first choice in the construction, manufacturing and packaging industries. Thanks to its outstanding advantages in speed and efficiency, wire nails help improve productivity and ensure safety during construction.

What are Wire Nails?

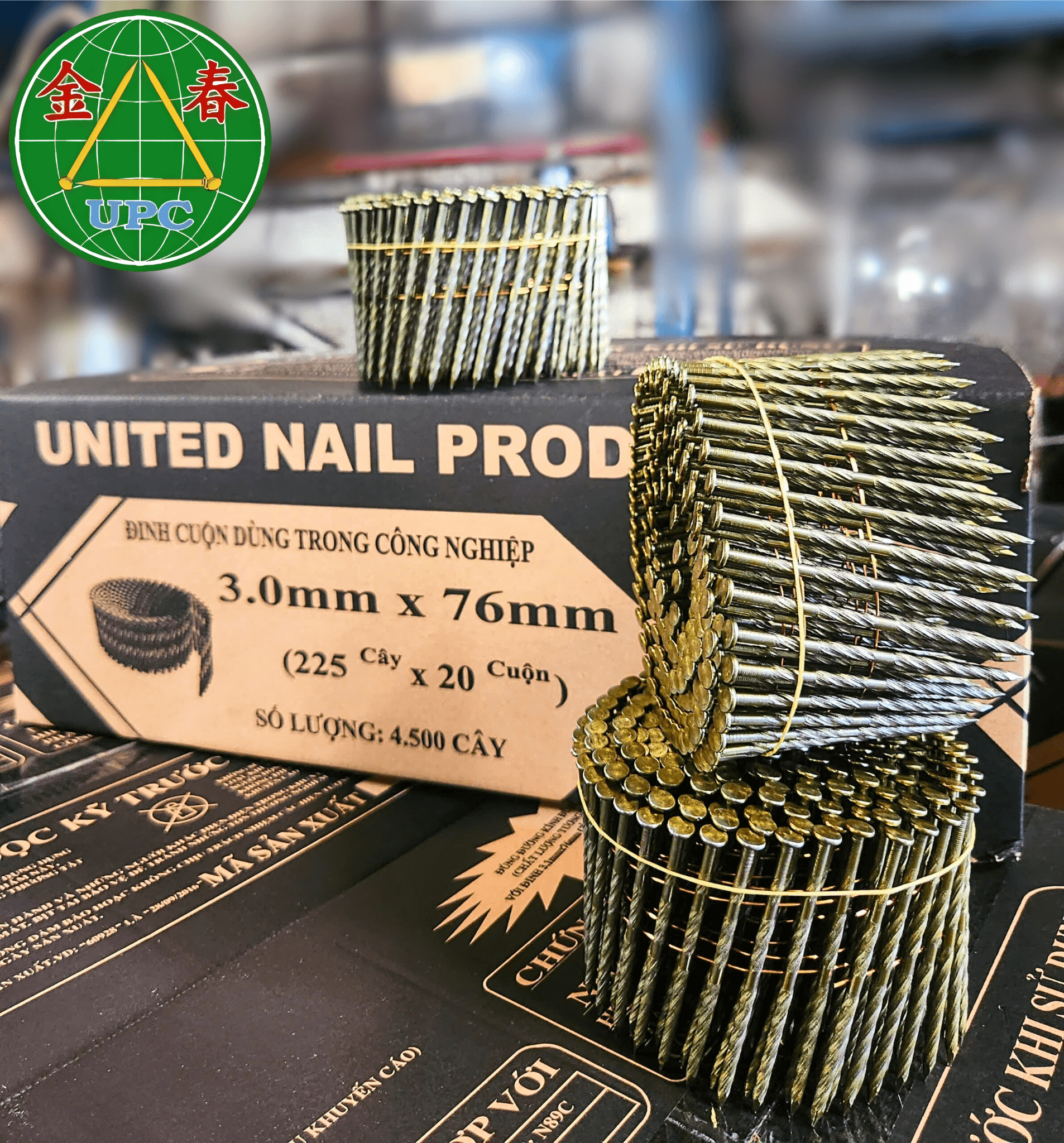

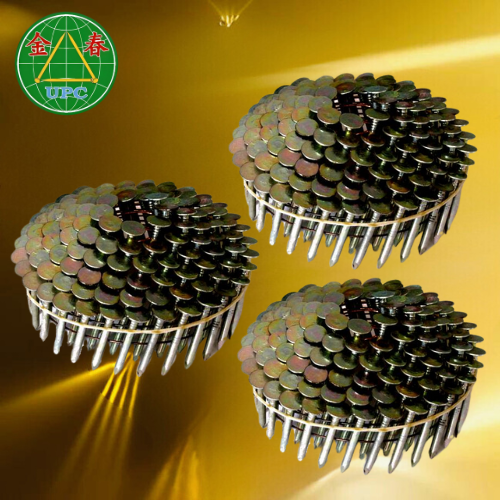

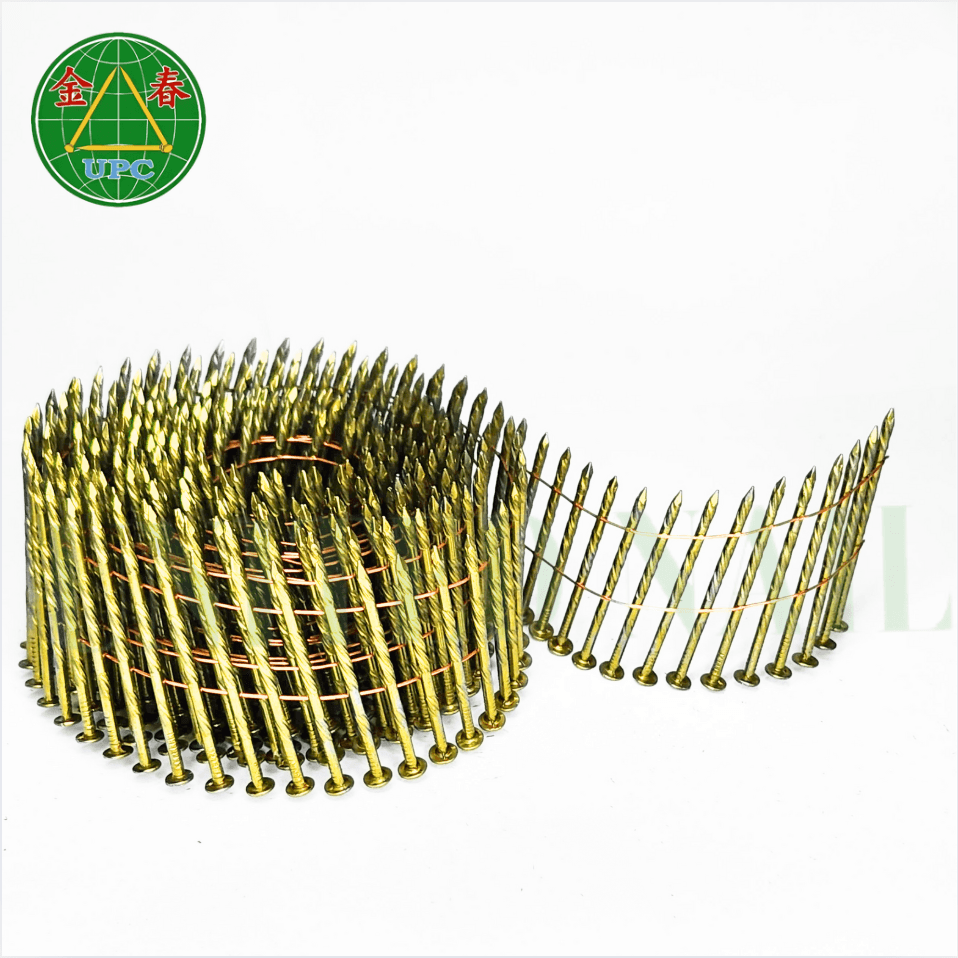

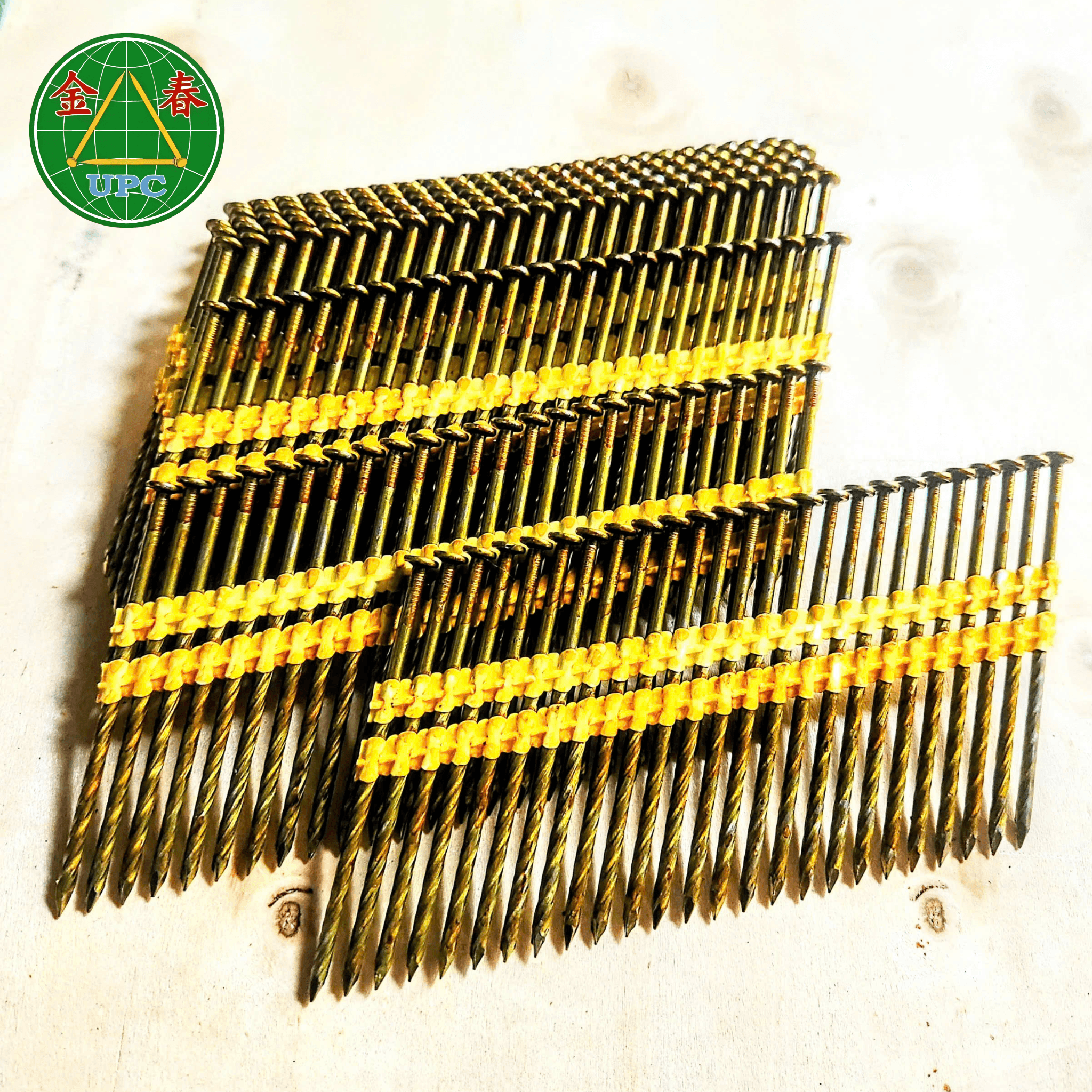

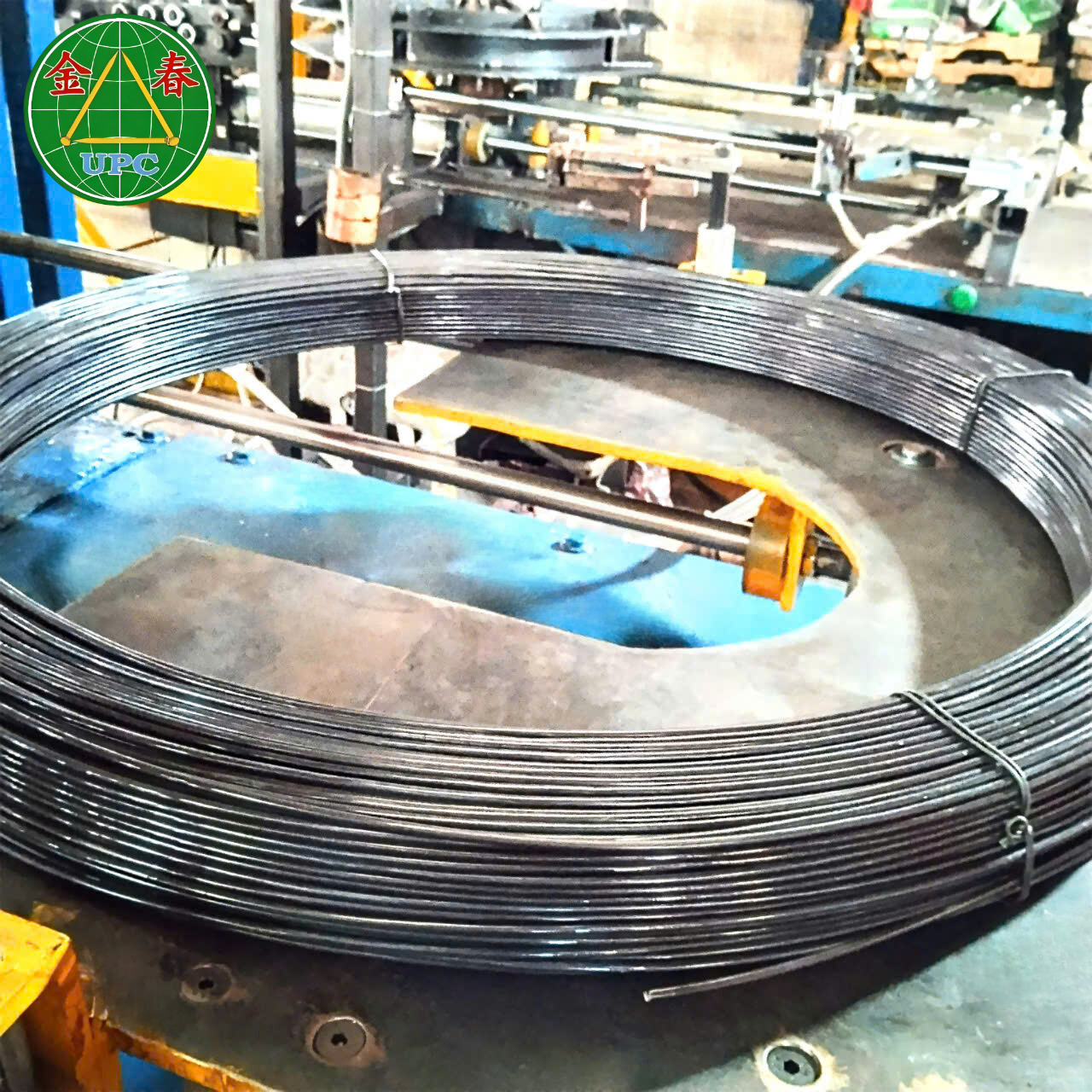

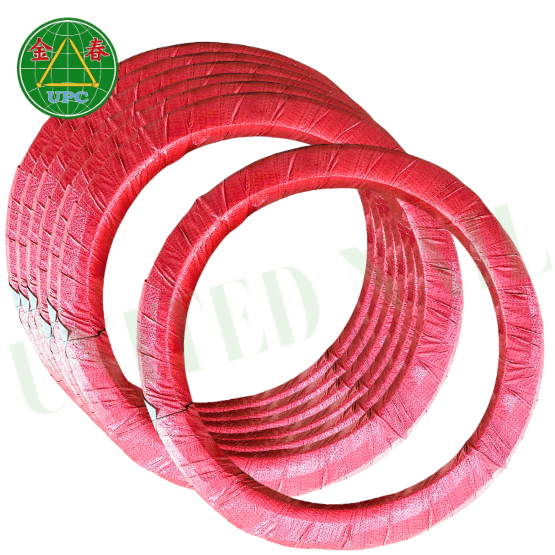

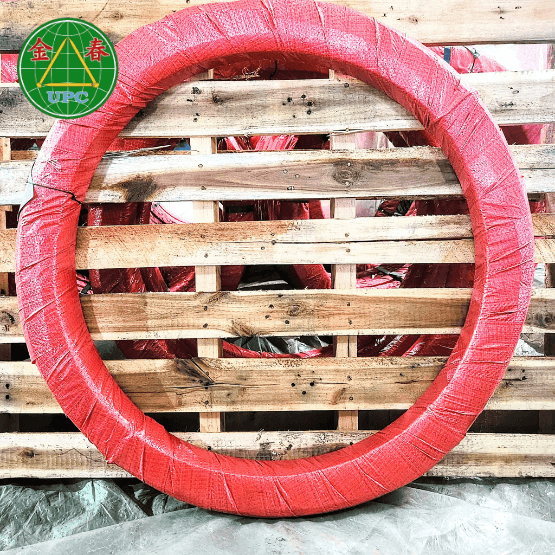

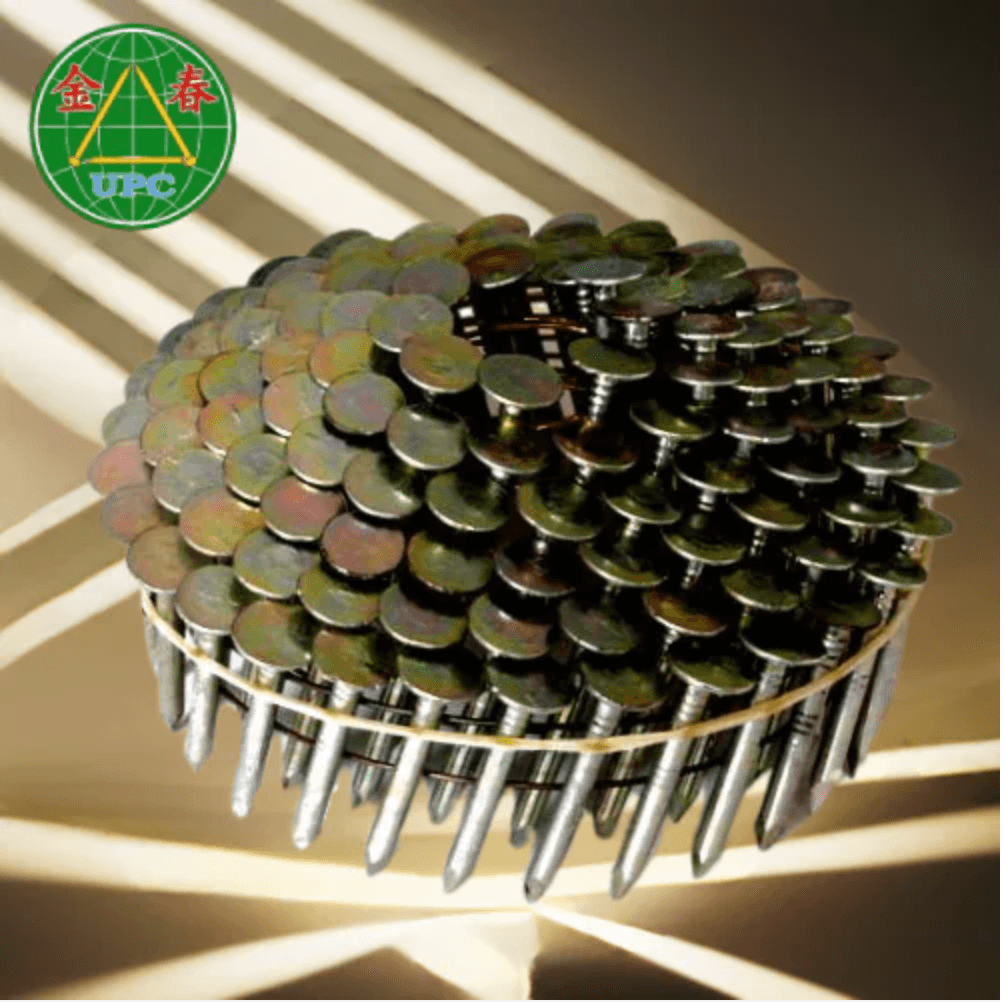

Wire nails, also known as coil nails (wire coil nails, coil pallet nails, coil framing nails, coil siding nails or coil roofing nails) are a type of nail specially designed for industrial use. Instead of being packaged individually, wire nails are linked together into a long roll with a metal wire, usually copper wire, helping to optimize the construction and assembly process.

Why choose wire nails?

Save time: Designed for use with a machine gun, helping to increase work speed and reduce labor.

High productivity: A wire can hold thousands of nails, meeting the needs of large projects.

Quality assurance: Manufactured according to technical standards, ensuring uniformity and high quality.

Safety: Using a nail gun helps reduce the risk of work accidents compared to using a traditional nail hammer.

Save time changing nails: No need to change continuously, helping the work go smoothly.

Wire nails / large cap roll nails

Detailed Information About Wire Nails

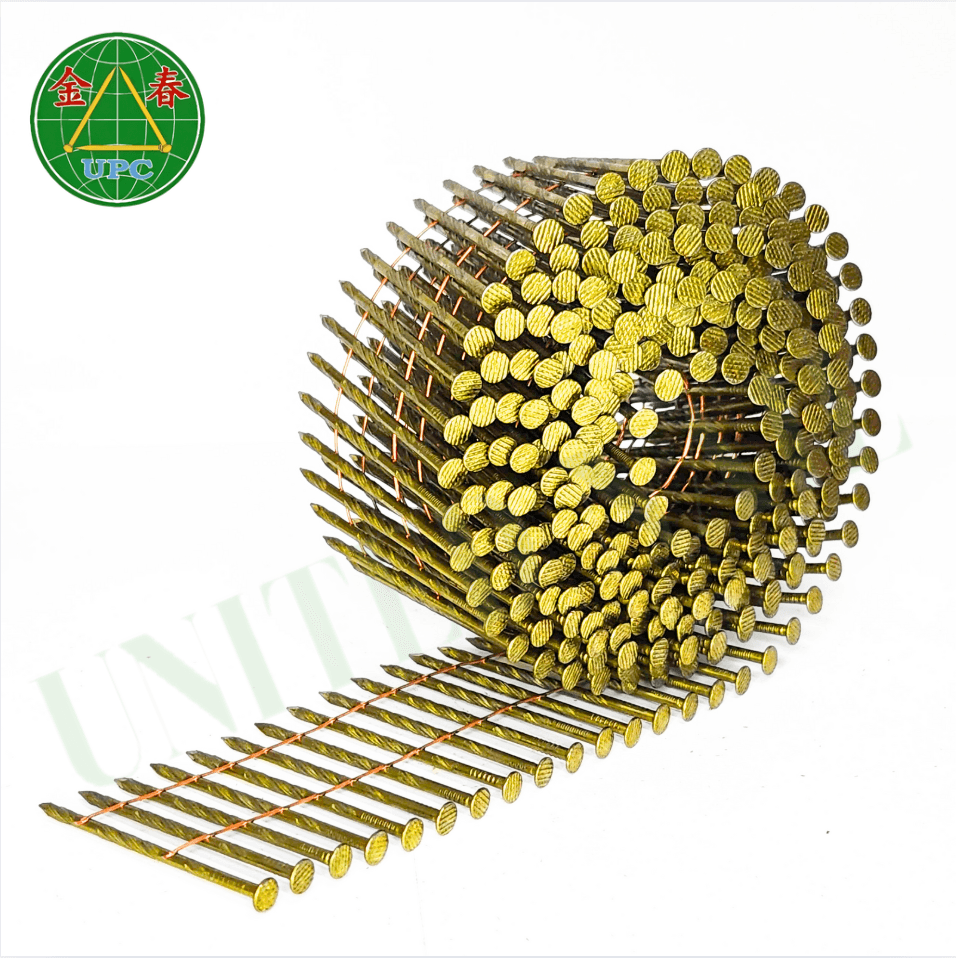

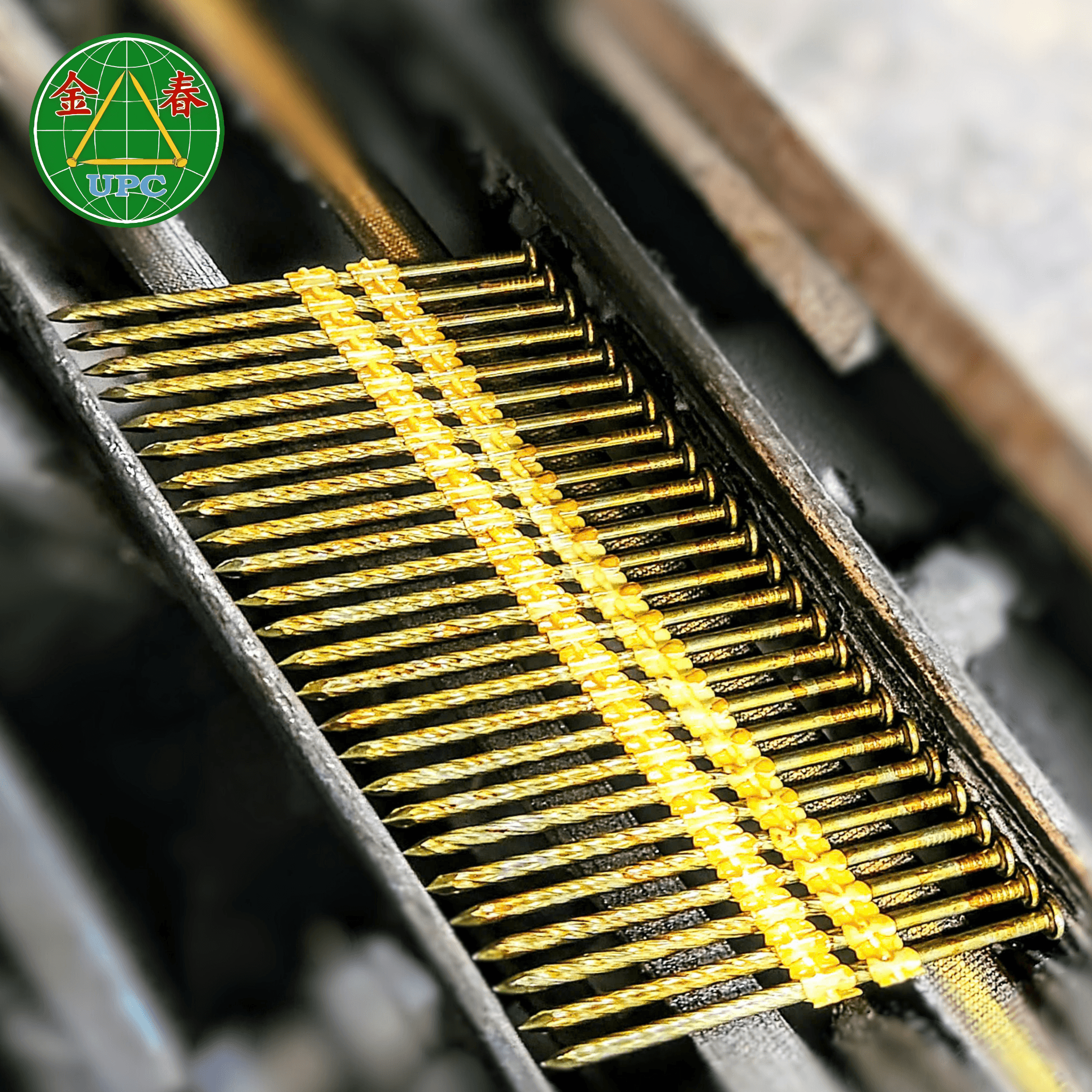

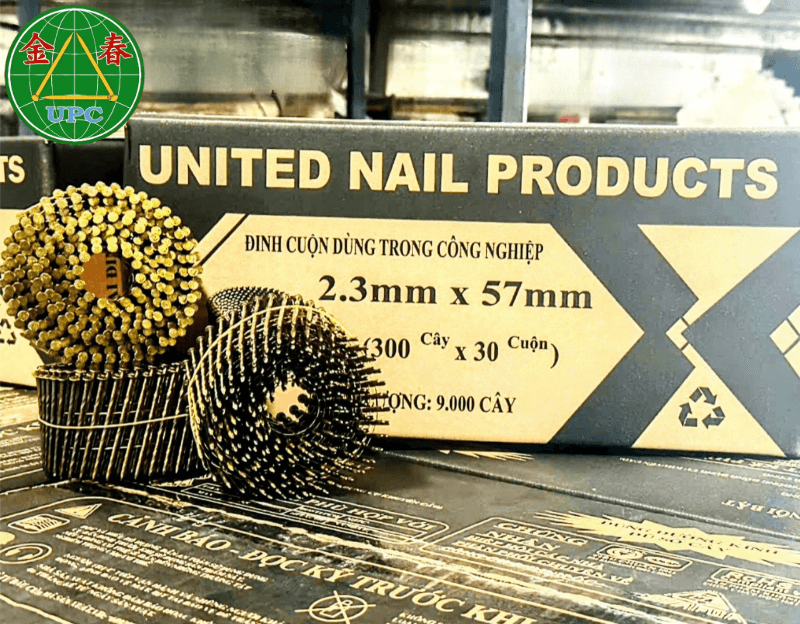

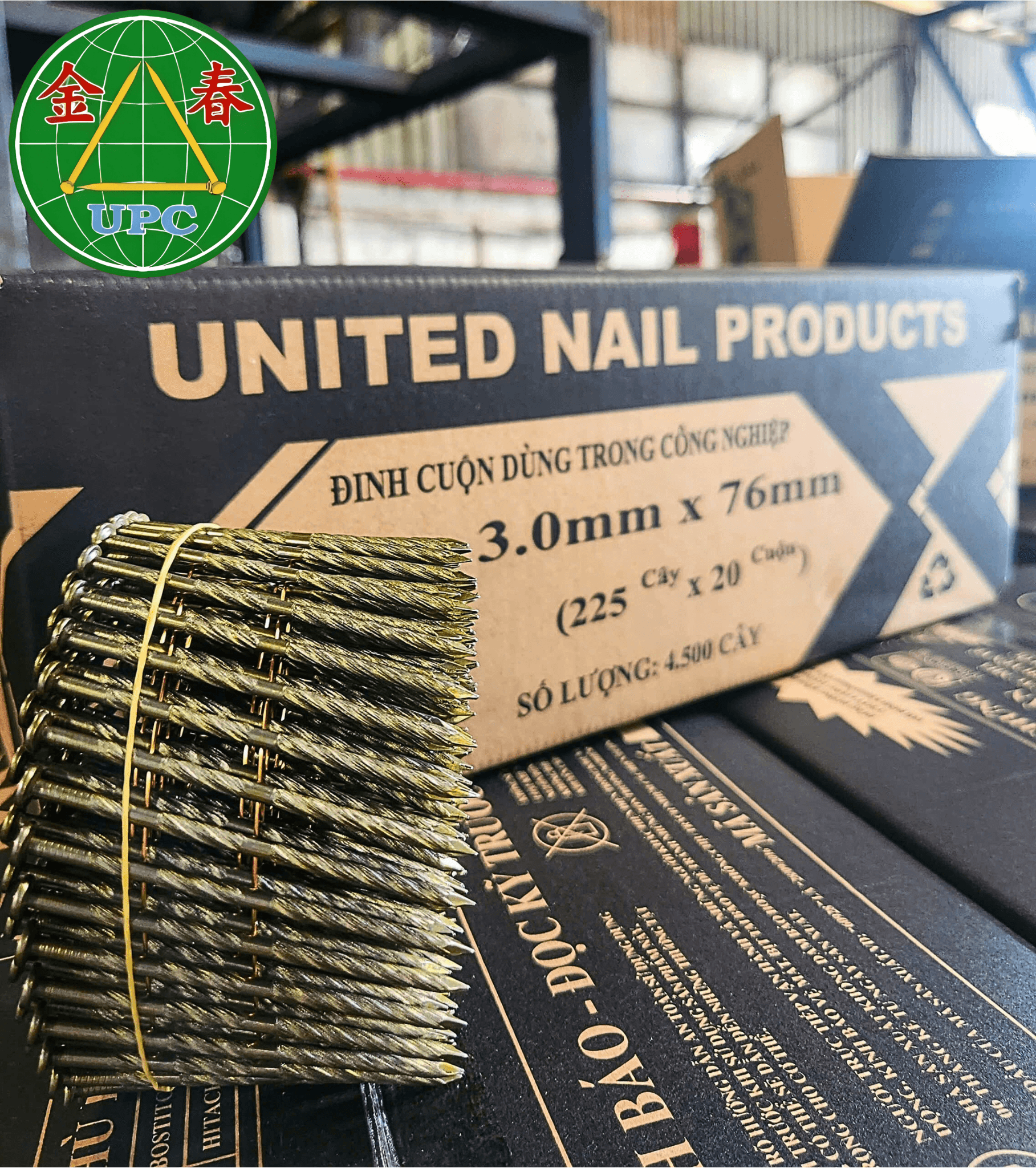

Currently, there are two popular types of wire nails on the market: smooth nails and spiral nails.

Nail body: There are two main types: smooth body and toothed body (round teeth or spiral teeth). The toothed type helps increase adhesion to the material.

Surface: Nails are often plated or dyed to increase aesthetics and oxidation resistance.

Nail tip: There are sharp and blunt tips, suitable for different purposes.

Packaging: Nails are linked into rolls with copper-plated steel wire, ensuring product durability and quality.

Outstanding Advantages of Wire Nails

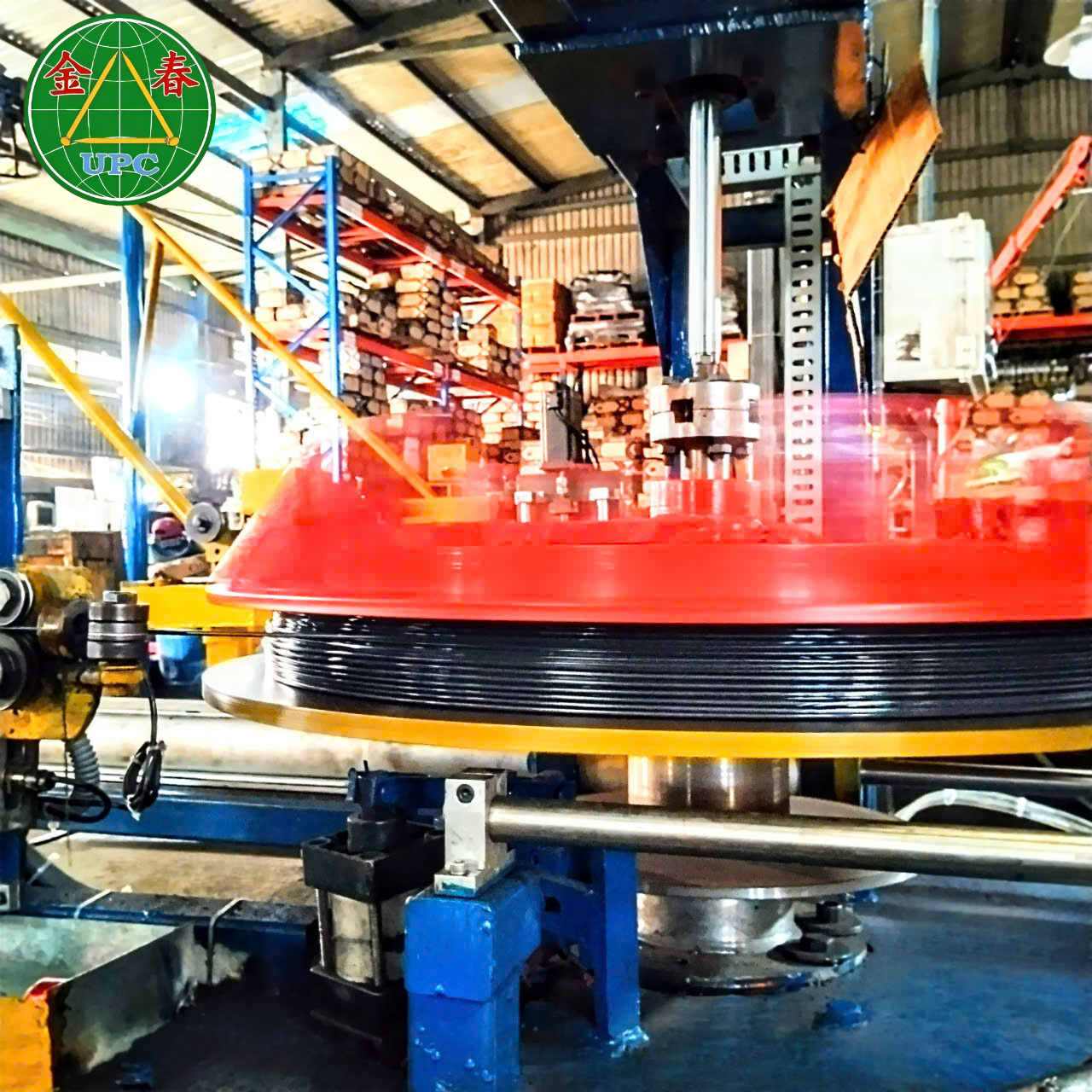

Modern technology: Nails are manufactured on advanced technology lines from Taiwan, ensuring precision and uniformity.

High quality: Nails are shiny, sharp, ensuring durability when used.

Good grip: The serrated or pointed design helps nails adhere firmly to wood materials.

Packing specifications: 120 sticks/roll, 60 rolls/carton, convenient for transportation and storage.

Applications:

1. Construction:

Pallet packing: Used to fix goods on pallets, creating sturdy and easy-to-move packages. This helps ensure that goods are not damaged during transportation.

Packing goods: Similar to palletizing, wire nails are also used to pack products into boxes and packages, ensuring that the goods are well preserved and do not shift during transportation.

Fixing wooden structures: Used to connect wooden bars, creating sturdy wooden frames for construction works.

2. Interior:

Woodworking production: Widely used in the production of wooden furniture, from household wooden furniture to industrial wooden furniture. It helps to connect the parts of wooden furniture firmly and quickly.

Picture framing: Used to fix wooden bars to picture frames, creating sturdy and beautiful picture frames.

3. Industrial production:

Woodworking industry: Similar to the interior field, the product is also widely used in the production of industrial wooden furniture, from wooden furniture to construction wooden furniture.

Packaging industry: Used to package products, protect products during transportation and storage.

How to choose quality nails:

Choose nails made of high-quality steel or galvanized to ensure durability and rust resistance.

Choose the length and diameter appropriate to the material.

Carefully check the nail head and nail body to ensure they are suitable for the intended use.

Avoid buying rusty nails and prioritize products from reputable manufacturers.

Tips:

Check carefully: Before buying, you should carefully check the quality.

Consult experienced people: If you are not sure, ask for advice from experienced people.

Choose the right size: Depending on the type of material to be nailed, choose the appropriate size.

Check the origin: You should choose to buy products from reputable brands to ensure quality.

CONCLUSION

Wire nails are one of the indispensable materials in construction works. With outstanding advantages, it is increasingly popular and widely used.

With outstanding advantages and the continuous development of technology, it promises to play an even more important role in the future. The application of technology in production will help the product become more complete, meeting the increasingly high requirements of the market. Wire nails are not only the present, but also the future of the manufacturing and construction industry.

If you are in need of buying nails, please contact United Nail Company for the best advice and support.