In the fast-paced world of construction and woodworking, every second counts. Efficiency, cleanliness, and reliability on-site often depend on small but crucial details—like the type of nails being used. Among the various collation systems available today, plastic strip nails have emerged as a preferred choice for professionals seeking smooth operation, consistent performance, and reduced downtime.

This article explores what plastic strip nails are, how they work, their advantages over other collation types, and why they’ve become the cleaner, more reliable solution for modern nail guns.

MỤC LỤC BÀI VIẾT

1. What Are Plastic Strip Nails?

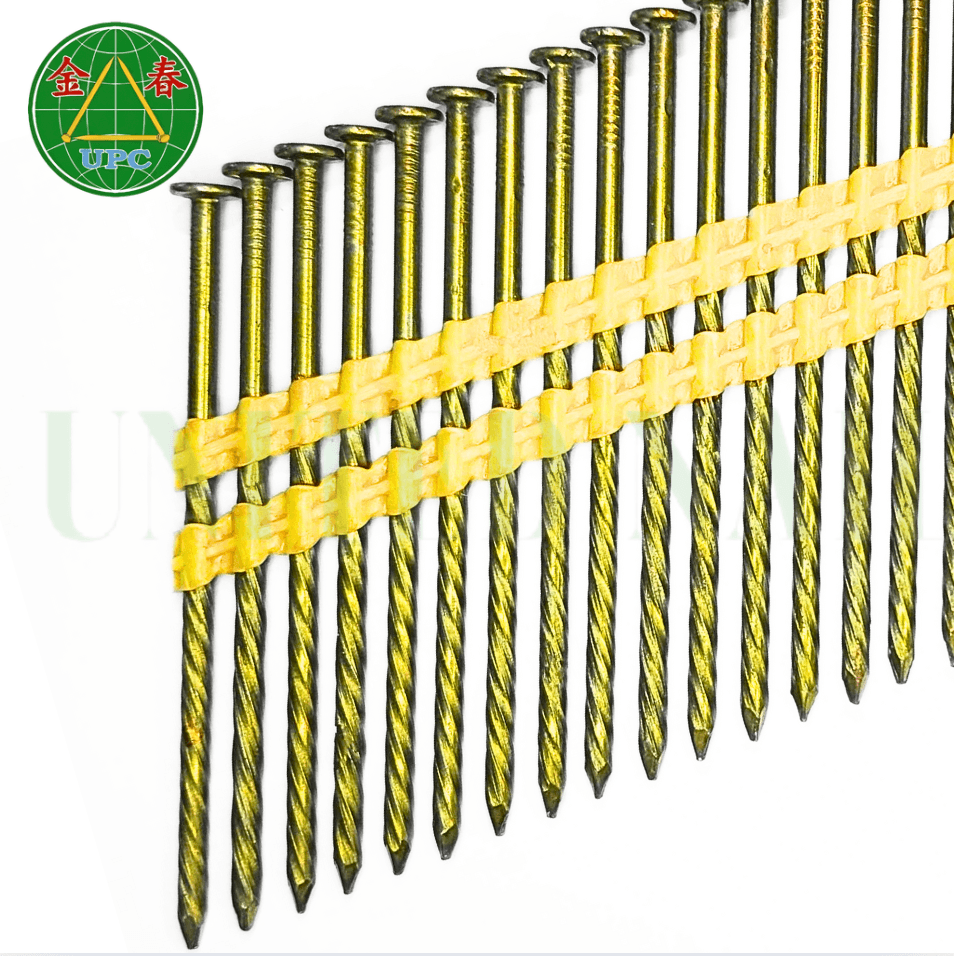

Plastic strip nails are a type of collated nail, meaning individual nails are connected together in strips using a thin layer of plastic. These strips are designed to feed smoothly into a nail gun, allowing for rapid and continuous firing without manually loading each nail.

The nails are typically held at angles ranging from 20° to 34°, depending on the nailer design. The plastic strip breaks apart cleanly upon firing, ensuring minimal residue and a consistent feed. This design makes them ideal for framing, sheathing, decking, subflooring, and other high-volume applications where speed and precision are critical.

2. How Plastic Strip Nails Differ from Other Collation Types

Collated nails can be joined together using different materials, mainly wire, paper, or plastic. Each type has its own advantages, but plastic collation stands out for its balance of durability, cost-effectiveness, and cleanliness.

| Collation Type | Main Material | Key Features | Common Uses |

|---|---|---|---|

| Wire Collated | Thin metal wire | Durable, suitable for outdoor use | Pallet assembly, fencing |

| Paper Collated | Adhesive paper tape | Cleaner finish, minimal debris | Interior framing, finishing |

| Plastic Collated | High-strength polymer | Moisture-resistant, consistent feed, versatile | Framing, decking, subflooring |

Plastic strip nails combine the strength of wire collation and the clean aesthetics of paper collation, while avoiding many of their drawbacks.

For instance, paper collated nails can lose adhesion when exposed to moisture, leading to feed jams. Wire collated nails may leave behind small pieces of wire that cause tool wear or safety hazards. Plastic collation minimizes both of these issues.

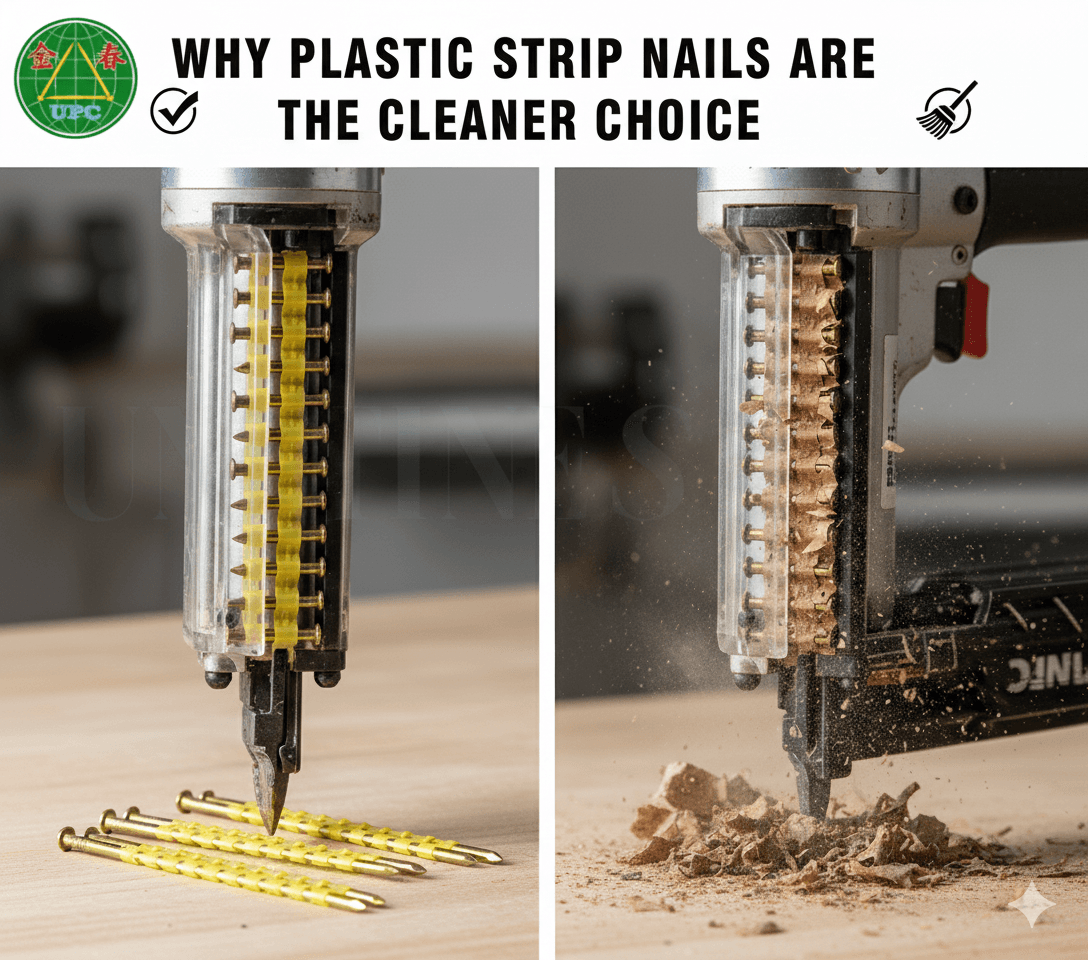

3. Why Plastic Strip Nails Are the Cleaner Choice

One of the biggest advantages of plastic strip nails is the cleanliness of operation. When fired, the plastic holding the nails together simply shatters into tiny fragments that are easily blown away or vacuumed up, without sticking to the work surface.

a. Less Debris, Less Cleanup

Unlike wire collation that leaves behind metal bits or paper collation that can jam when damp, plastic fragments are dry, light, and non-sticky. This keeps the workspace tidy and helps maintain consistent airflow in pneumatic nailers, reducing maintenance.

b. No Glue Build-Up

Because the nails are not glued together (as in paper collation), there’s no residue that can accumulate inside the nail gun. Over time, this means less frequent cleaning and fewer misfires—a significant advantage in high-volume production environments.

c. Smooth, Even Drive

Plastic collated nails separate uniformly upon firing, allowing the gun’s driver blade to move without obstruction. This results in cleaner nail heads and flush finishes, even on dense materials like treated lumber or composite decking.

4. Reliability That Keeps the Job Moving

Plastic strip nails are also valued for their feeding reliability and moisture resistance, especially in outdoor or humid environments.

a. Consistent Feeding

Each strip is precisely molded to maintain equal spacing and alignment between nails. This consistency ensures smooth feeding through the magazine and reduces jamming—one of the most frustrating issues for nail gun operators.

b. Resistant to Humidity and Rain

Unlike paper collation, plastic strips do not absorb moisture. This prevents swelling or softening that could lead to misalignment. Whether stored on a damp jobsite or used outdoors, plastic collated nails remain stable and reliable.

c. Durability During Transport

Plastic strips hold nails securely in place during shipping and handling. They don’t tear or warp easily, which means fewer broken strips and less waste before the nails even reach the jobsite.

5. Compatibility and Versatility

Plastic strip nails are designed for a wide variety of framing and full-round-head nailers, including popular brands like Hitachi, Makita, Bostitch, and DeWalt. The standard collation angles—typically 21°, 28°, and 34°—ensure compatibility with most pneumatic and gas-powered nail guns.

In addition, they come in many different materials, coatings, and sizes, including:

Bright, galvanized, or stainless steel for different corrosion protection levels

Smooth, ring, or screw shanks for varying holding power

Lengths from 2” to 3-½” (50mm to 90mm) to suit framing, decking, or fencing applications

This wide range of options makes plastic strip nails one of the most adaptable solutions for both residential and industrial projects.

6. Safety Advantages

Every professional knows that tool safety goes hand in hand with efficiency. Plastic strip nails contribute to safer work environments in several ways:

Reduced ricochet risk: Unlike wire collation, there are no leftover metal pieces that can rebound after firing.

Improved visibility: The absence of paper debris means operators have a clearer view of the nailing surface.

Stable feeding: Fewer jams or double-fires reduce the chance of accidents caused by sudden tool recoil.

By minimizing the risk of tool malfunction and jobsite debris, plastic collated nails make nail gun operation smoother and safer.

7. Economic Benefits: Cost vs. Performance

While the price per nail may be slightly higher than that of wire collated nails, the overall cost efficiency of plastic strip nails often ends up being superior. Here’s why:

Less downtime: Fewer jams mean more continuous work time.

Lower maintenance costs: Less cleaning and fewer part replacements.

Reduced material waste: Plastic strips don’t corrode or break as easily in storage.

Faster operation: Quick loading and smooth firing improve overall productivity.

For contractors managing tight deadlines, these savings in time and maintenance can easily outweigh the small difference in material cost.

8. Environmental Considerations

One criticism of plastic collated nails has been their contribution to plastic waste. However, modern manufacturers are actively addressing this concern. New developments include:

Recyclable plastic strips, often made from polypropylene (PP) or polyethylene (PE).

Biodegradable polymers that break down naturally over time without leaving toxic residues.

Cleaner production methods that minimize energy consumption during molding and collation.

Many suppliers now offer eco-friendly options designed to meet the growing demand for sustainable construction materials, without sacrificing the performance and reliability professionals expect.

9. Tips for Selecting High-Quality Plastic Strip Nails

To get the best results, it’s essential to choose plastic strip nails that match both your tool specifications and job requirements. Here are a few guidelines:

Match the collation angle to your nailer (check the tool’s manual).

Verify nail head type — full round or clipped — based on project and code requirements.

Check coating and material: use galvanized or stainless steel for outdoor projects.

Inspect packaging: look for even collation, clean plastic bonding, and intact strips.

Buy from verified suppliers who can provide test reports and quality certifications.

Investing in consistent, high-quality nails helps prevent tool wear, ensures structural integrity, and keeps job performance predictable.

10. Future Outlook

As jobsite technology evolves, so does the hardware that supports it. The rise of automated nailing systems and robotic fastening in industrial production is pushing demand for nails that offer perfect alignment and reliable feeding. Plastic strip nails are uniquely positioned to meet these demands thanks to their dimensional precision and mechanical consistency.

In the coming years, we can expect even more innovation—such as low-fragmentation collations for cleaner workspaces and smart packaging that reduces plastic usage while improving storage efficiency.

Conclusion

From framing houses to assembling pallets, plastic strip nails have proven themselves as a cleaner, more reliable, and more efficient choice for professionals worldwide. Their combination of moisture resistance, smooth feeding, and consistent drive makes them ideal for today’s demanding construction environments.

As manufacturers continue to refine plastic materials and develop eco-friendly alternatives, plastic strip nails are likely to remain the standard of reliability in nail gun technology—helping builders work faster, safer, and cleaner on every project.

Contact information

UNITED NAIL PRODUCTS CO., LTD

Address: 16A8, Tra Noc Industrial Zone 1, Tra Noc Ward, Binh Thuy District, Can Tho City, VietNam

Phone: (+84) 986 831838; (+84) 292 242165

Email: sales5@unitednail.com

Thank you for reading this article, hope the information is useful to you.