In Vietnam’s dynamic industrial hubs, where factories fuel global trade with everything from furniture to agricultural exports, the demand for reliable fasteners is soaring. At United Nail Products Co. Ltd, our Industrial Wire Nails, crafted from high-quality carbon steel sourced from trusted Vietnamese partners, are transforming industries. These precision-engineered nails secure wooden crates, reinforce furniture, and stabilize construction projects, all while promoting sustainability. Far beyond traditional fasteners, Industrial Wire Nails reduce waste, enhance durability, and meet the rigorous standards of markets like Japan, Canada, Thailand, and beyond. This article explores how these nails are empowering businesses to build stronger products and a greener future.

MỤC LỤC BÀI VIẾT

Why Industrial Wire Nails Are Critical for Diverse Industries

Global trade relies on robust materials to package and transport goods securely. From wooden crates protecting electronics to furniture enduring daily use, the quality of fasteners directly impacts efficiency and sustainability. Industry reports estimate that over 1.5 billion wooden crates and containers are used annually, with millions failing due to poor fastening. In construction and furniture manufacturing, low-quality nails contribute to structural weaknesses, leading to costly repairs and waste. Studies suggest that up to 35% of crate and furniture failures stem from inadequate fasteners, driving up costs and environmental impact.

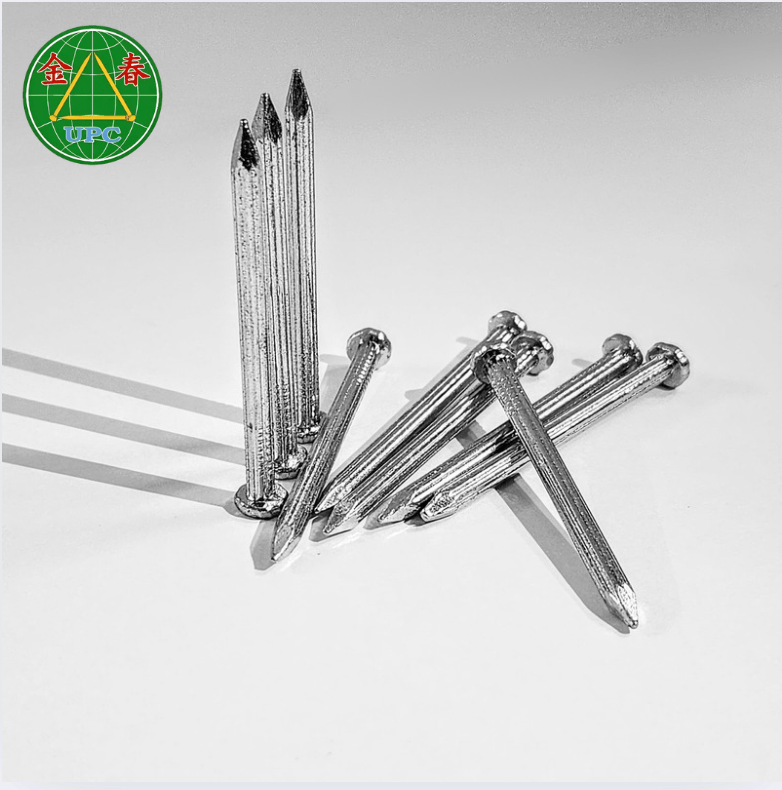

Industrial Wire Nails

United Nail’s Industrial Wire Nails address these challenges with precision and strength. Designed to minimize material waste and enhance product longevity, they support eco-friendly practices across industries. These nails meet the demands of export markets like Japan, Canada, Thailand, the United States, Italy, and Australia, enabling businesses to deliver durable, sustainable products. By choosing Industrial Wire Nails, manufacturers invest in reliability and environmental responsibility.

The Power of Industrial Wire Nails: Key Features for Versatile Applications

Our Industrial Wire Nails are engineered for performance and sustainability, making them ideal for diverse applications. Here’s why they stand out:

- Precision Craftsmanship: Manufactured with tight tolerances, Industrial Wire Nails ensure accurate placement in automated systems, reducing misfires and material damage by up to 26%, conserving resources.

- Automation Efficiency: Compatible with high-speed pneumatic nail guns, these nails streamline production, cutting energy use and labor costs by up to 22% compared to manual methods.

- Export-Ready Durability: Compliant with international standards like ISPM 15 for wooden packaging, Industrial Wire Nails withstand rough handling and diverse climates, from Japan’s humidity to Canada’s cold winters.

- Corrosion Resistance: Coated with advanced galvanized or stainless-steel layers, our nails resist rust, ensuring longevity in humid markets like Thailand and coastal regions.

- Versatile Design: Available in lengths from 1.25 to 3.5 inches and shank types (smooth, ring, or screw), Industrial Wire Nails suit applications like wooden crates, furniture frames, construction bracing, and industrial fencing.

These features make Industrial Wire Nails a versatile solution, driving efficiency and sustainability across global industries.

A Story of Ambition: Minh’s Journey with Industrial Wire Nails

Minh, a factory manager in Hai Phong, Vietnam, oversees a production line crafting wooden crates and furniture for a textile and home decor exporter. His company aimed to secure a contract with a Japanese retailer demanding eco-friendly packaging and durable products, but outdated nails were a bottleneck. Low-quality fasteners caused crate failures during shipping and weakened furniture joints, leading to 28% material waste monthly. The inefficiencies delayed deliveries, and the environmental toll clashed with the company’s sustainability goals. Minh faced the challenge of meeting Japan’s stringent standards while reducing waste.

When Minh’s team adopted United Nail’s Industrial Wire Nails, the results were transformative. Using automated pneumatic nail guns, they doubled crate production to 500 units daily and reduced wood waste by 26%. The nails’ precision strengthened furniture frames, and their durability ensured crates survived long sea voyages to Tokyo. Minh’s factory earned a sustainability certification, securing the Japanese contract and gaining recognition from importers in Canada and Thailand. His story inspires manufacturers, proving Industrial Wire Nails can elevate quality and sustainability in global trade.

Best Practices for Maximizing Industrial Wire Nails in Manufacturing

To unlock the full potential of Industrial Wire Nails, manufacturers can follow these best practices:

- Invest in Advanced Tools: Use high-performance pneumatic nail guns designed for Industrial Wire Nails to ensure seamless operation. Regular maintenance, like cleaning and lubricating, prevents jams and extends tool life.

- Select Optimal Nail Specifications: Choose nail lengths (e.g., 1.5–3 inches) and shank types based on material and application. Ring-shank nails offer extra grip for softwood crates, while screw-shank nails excel in hardwood furniture.

- Train for Efficiency and Safety: Educate workers on nail gun techniques, such as consistent pressure and angle, to maximize accuracy and minimize waste. Safety training reduces workplace accidents.

- Source Sustainable Materials: Pair Industrial Wire Nails with FSC-certified wood for crates and furniture to enhance eco-credentials, appealing to markets like Japan and Europe.

- Implement Quality Control: Regularly inspect crates, furniture, and structures during production and post-shipping to ensure nail strength. Use inspection data to optimize processes.

These steps ensure Industrial Wire Nails deliver maximum efficiency and sustainability across applications.

The Global Impact of Industrial Wire Nails in Trade and Sustainability

The global demand for sustainable manufacturing is reshaping industries, and Industrial Wire Nails are leading the way. By reducing waste and energy use, our nails help businesses lower their carbon footprint, aligning with the United Nations’ Sustainable Development Goals. In Japan, where strict regulations govern packaging, Industrial Wire Nails ensure compliance for wooden crates. In Canada, furniture manufacturers rely on our nails for durable joints that withstand harsh winters. In Thailand, construction firms use them for robust bracing, while in Italy and Australia, exporters leverage them for eco-friendly packaging. Vietnam’s reputation as a sustainable manufacturing hub grows with our nails.

United Nail’s commitment to sustainability extends beyond products. Our Vietnamese facilities use energy-efficient processes, and we partner with suppliers prioritizing sustainable sourcing. We invest in research to develop advanced coatings, ensuring Industrial Wire Nails remain at the forefront of green innovation. By choosing our nails, businesses join a global movement to protect the planet.

Case Studies: Real-World Success with Industrial Wire Nails

The versatility of Industrial Wire Nails shines across industries. A Vietnamese electronics exporter shipping to Canada used our nails for wooden crates, reducing crate failures by 20% and saving thousands in damaged goods. In Italy, a furniture manufacturer adopted Industrial Wire Nails, cutting wood waste by 24% and earning eco-certifications. In Thailand, a construction firm used our nails for industrial fencing, increasing structural durability by 30% and securing contracts in Australia. These cases highlight how Industrial Wire Nails drive cost savings, efficiency, and sustainability.

In Vietnam, small businesses also thrive. A family-owned workshop in Ho Chi Minh City switched to Industrial Wire Nails for crate and furniture production, boosting output by 33% and securing deals with European clients. These success stories show how Industrial Wire Nails empower businesses of all sizes to excel in global markets while prioritizing sustainability.

Partner with United Nail for Industrial Wire Nails and a Sustainable Future

At United Nail Products Co. Ltd, we believe small components spark big change. Our Industrial Wire Nails, crafted from high-quality carbon steel sourced from trusted Vietnamese partners, empower manufacturers to create durable crates, furniture, and structures ready for global trade. From Minh’s factory in Hai Phong to exporters in Japan and Canada, our nails are building a sustainable future. Whether you’re shipping electronics to Toronto or crafting furniture for Rome, United Nail is your partner in precision and sustainability.

Contact us today to request a quote, order samples, or explore how Industrial Wire Nails can transform your operations. Together, let’s craft a future where every product carries the promise of a healthier planet.

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production

Thank you for taking the time to read this article. We hope the information proves helpful to you.