When it comes to construction, furniture manufacturing, or general carpentry, small details make a big difference — and steel nails are one of those details. Though they seem simple, nails are responsible for holding structures together, ensuring stability, and maintaining long-term durability. Choosing poor-quality nails can lead to rust, weak joints, and costly rework.

Whether you’re a builder, wholesaler, or procurement officer sourcing from manufacturers, knowing how to identify high-quality steel nails before making a purchase is crucial. This guide breaks down everything you should look for — from raw materials to testing methods — so you can make informed buying decisions and protect your projects from hidden defects.

MỤC LỤC BÀI VIẾT

1. Start with the Steel Grade

The foundation of any steel nail’s quality lies in the type of steel wire used. Nails can be made from several grades of steel, each offering different strength, flexibility, and corrosion resistance.

Low Carbon Steel (e.g., SAE 1018, Q195, Q235):

Common for general-purpose nails, tie wire nails, and construction use. These nails are flexible and easy to drive but may require coating to resist rust.Medium Carbon Steel (e.g., 1045, 1050):

Offers greater hardness and holding power — suitable for framing or heavy-duty use.High Carbon Steel (e.g., 1070 and above):

Extremely strong but less ductile. Used for specialty nails where shear strength is critical.

If you are sourcing nails for export or large-scale projects, ask your supplier for a Material Test Certificate (MTC) showing the steel’s chemical composition and tensile strength. Reliable manufacturers will be able to provide this without hesitation.

2. Examine Surface Treatment and Coating

Corrosion is the biggest threat to steel nails, especially in humid or outdoor environments. High-quality nails always come with a protective coating. Here are the most common types:

Bright Finish (Uncoated) Steel Nails:

Suitable for indoor applications where moisture isn’t a concern. Shiny and smooth, but prone to rust over time.Electro-Galvanized (EG) Steel Nails:

Thin zinc coating applied via electroplating. Provides light corrosion resistance, ideal for furniture or interior decoration.Hot-Dip Galvanized (HDG) Steel Nails:

Thicker and more durable zinc layer applied through dipping in molten zinc. Excellent for roofing, fencing, and outdoor structures.Vinyl-Coated or Cement-Coated Steel Nails:

These coatings improve grip and holding power when driven into wood. Common in framing or coil nails.

When comparing samples, inspect the nail’s surface under good light. A quality coating should be even, smooth, and free of bubbles, flakes, or dark spots. Uneven or patchy coatings suggest poor galvanizing or contamination during production.

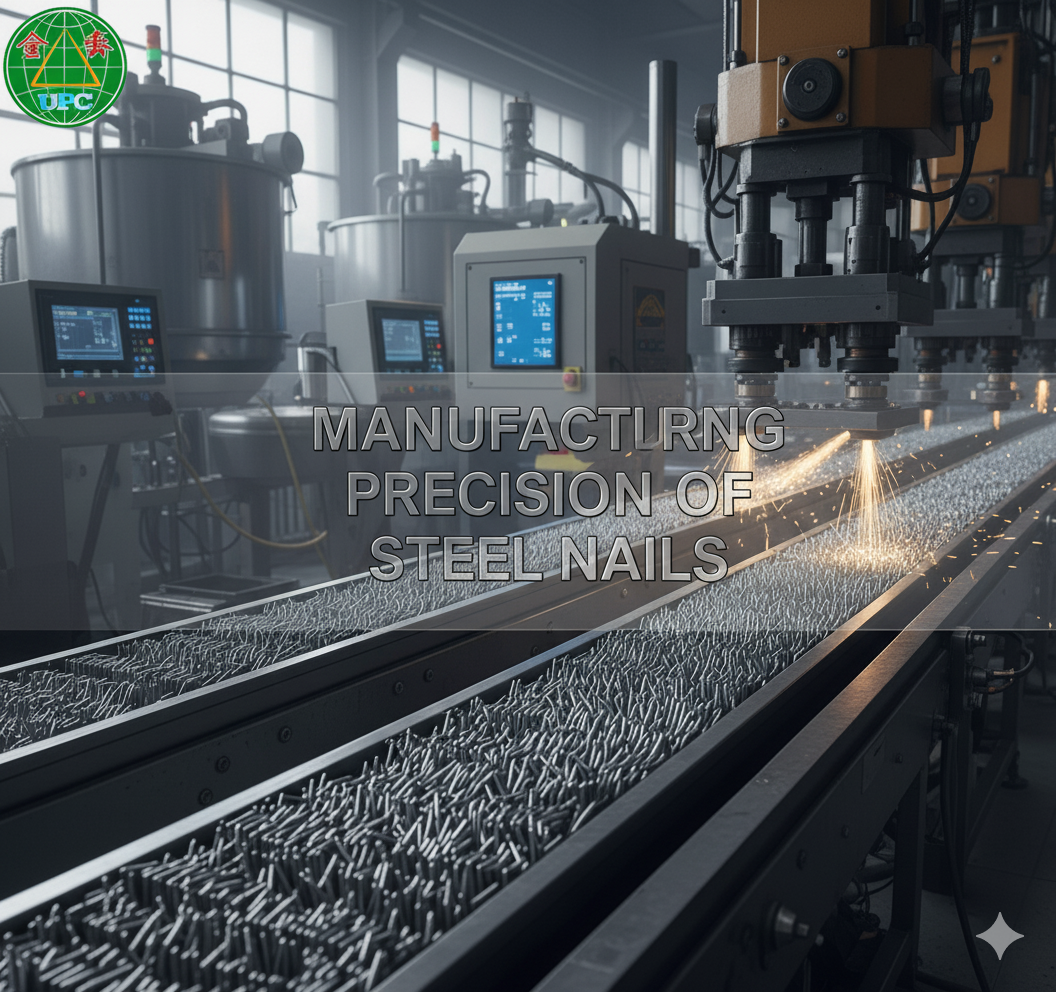

3. Check the Manufacturing Precision

High-quality steel nails are the result of precise manufacturing — every millimeter counts. Look closely at the head, shank, and tip:

a. Head

Should be flat, centered, and uniform in diameter.

Off-centered heads cause mis-hits, damaging wood or reducing driving efficiency.

For coil or strip nails, the collation should be tight and consistent — loose wires or uneven spacing are red flags.

b. Shank

Examine whether it’s straight and consistent in thickness.

For specialized types (ring shank, screw shank), the pattern should be cleanly formed without burrs or distortion.

Poorly drawn wire or worn dies can cause uneven diameters and breakage under pressure.

c. Point

A sharp, clean-cut point allows smooth penetration.

Blunt or uneven tips increase the chance of splitting wood or bending during nailing.

A simple visual inspection or comparison between brands can quickly reveal differences in manufacturing quality.

4. Assess Strength and Flexibility

Good steel nails must strike a balance between hardness and ductility. Too hard, and they become brittle; too soft, and they bend easily.

If possible, conduct a bend test:

Hold the nail with pliers and bend it to about 45–60 degrees. A high-quality nail should bend slightly without cracking or snapping. This indicates proper annealing and consistent carbon content.

For larger buyers, request mechanical test reports that show:

Tensile Strength (MPa)

Yield Strength

Elongation percentage

These figures give a clear picture of how the nails will perform under load and impact.

5. Evaluate Nail Packaging and Labeling

Packaging may seem minor, but it says a lot about the manufacturer’s attention to quality control. Look for:

Consistent labeling with product name, size, steel grade, coating type, and weight.

Moisture-resistant packing materials, especially for sea shipments.

Neat and uniform coils or cartons.

Export-grade packaging should protect the nails from humidity and rust during long transit times. When buying in bulk, always check whether the weight per carton matches the specification — inaccurate weights can indicate short counts or inconsistent production.

6. Verify Compliance and Standards

A reputable manufacturer will comply with international standards such as:

ASTM F1667 (U.S. Standard for Nails, Spikes, and Staples)

EN 10218 / EN 14592 (European Standards for Fasteners)

JIS B 2808 (Japanese Industrial Standard)

Ask for certifications or product datasheets that confirm the nails were tested against these benchmarks. This ensures uniformity and safety across batches.

If you are importing nails, also verify whether the supplier has ISO 9001:2015 certification, which demonstrates a structured quality management system.

7. Inspect Samples Before Bulk Purchase

Never skip the sampling stage. Before placing a large order, request product samples from at least two or three suppliers. Here’s how to evaluate them:

Visual inspection: check for uniform size, smooth coating, and clean finish.

Functional test: drive a few nails into a wooden board; note if any bend or split the wood.

Rust test: leave samples exposed to air or humidity for a few days and compare corrosion levels.

Keep a sample from each lot as a reference for future shipments, ensuring consistency over time.

8. Ask About the Manufacturing Process

Transparent suppliers are usually trustworthy. Don’t hesitate to ask how the nails are made and what quality control steps are in place. A reliable steel nails manufacturer should be able to explain:

Wire drawing and heat treatment process

Surface cleaning and galvanizing methods

Dimensional and hardness testing procedures

Final inspection criteria before packing

Factories that invest in automatic wire drawing machines, galvanizing lines, and nail collators typically produce more consistent results than small manual workshops.

9. Consider the Supplier’s Reputation

Beyond the product itself, the steel nails manufacturer’s reputation and service play a major role in ensuring long-term quality. When sourcing from platforms like Alibaba or Global Sources:

Check the steel nails supplier’s years of experience, certifications, and verified business status.

Review customer feedback and trade history.

Evaluate how quickly they respond to inquiries and how clearly they answer technical questions.

A professional supplier values long-term cooperation and won’t compromise quality just to offer the lowest price.

10. Balance Price with Value

Cheap nails often come at a hidden cost — weak bonding, rust, and rework expenses. While pricing is important, remember that a small difference per kilogram can translate into major differences in performance and lifespan.

Compare unit price alongside specification details (steel grade, coating, tensile strength). The best deal is not the lowest price, but the one that guarantees consistent, reliable performance in real-world conditions.

Conclusion: Quality Nails Build Quality Projects

Steel nails may be small, but their role in construction is enormous. Every bend, every point, and every zinc layer contributes to the safety and durability of what you build. Before buying, always look beyond appearance and price — verify materials, inspect coatings, and understand the manufacturing process.

In short:

Check steel grade and mechanical strength.

Inspect surface coating and precision.

Verify standards, samples, and supplier reputation.

Doing so ensures that your nails — and the structures they support — will stand the test of time.

Contact information

UNITED NAIL PRODUCTS CO., LTD

Address: 16A8, Tra Noc Industrial Zone 1, Tra Noc Ward, Binh Thuy District, Can Tho City, VietNam

Phone: (+84) 986 831838; (+84) 292 242165

Email: sales5@unitednail.com

Thank you for reading this article, hope the information is useful to you.