The Journey to Create High-Quality Plastic Strip Nail Products at United Nail

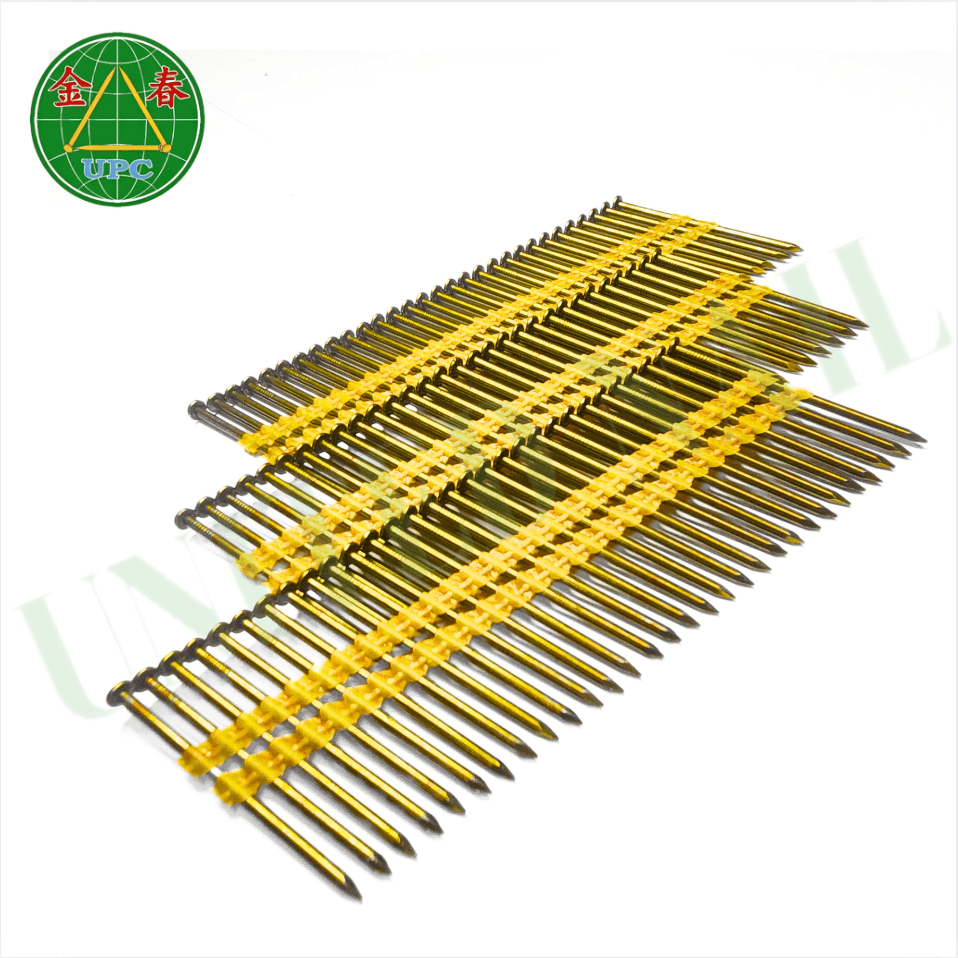

In the construction and manufacturing industries, Plastic Strip Nails are indispensable components that streamline work processes and increase productivity. These nails, bound together by durable plastic strips, are designed for use in nail guns and are preferred for their consistent performance and efficiency. As a leader in the production of plastic strip nails, United Nail has made significant strides in developing high-quality products that meet the demanding needs of global markets.

This article will explore the comprehensive journey that United Nail undertakes to create its industry-leading plastic strip nails. From sourcing raw materials to adhering to rigorous quality standards, each step in the production process reflects United Nail’s commitment to excellence, innovation, and sustainability.

MỤC LỤC BÀI VIẾT

Understanding the Demand for Plastic Strip Nails

Before diving into the intricate production process, it’s essential to understand the growing demand for plastic strip nails. These nails are highly popular in construction because they enable faster, more efficient work. Unlike traditional loose nails, plastic strip nails are arranged in a convenient strip format, allowing builders to drive them in rapid succession using a nail gun. This not only speeds up the work but also ensures consistent nail placement, reducing the chance of mistakes or misalignment.

The United Nail Approach to Quality Manufacturing

United Nail has been a recognized leader in the nail manufacturing industry for over a decade. We success is largely attributed to their strict quality control measures and dedication to continuous improvement. At the core of United Nail’s production philosophy is the belief that high-quality products start with high-quality materials and precision engineering.

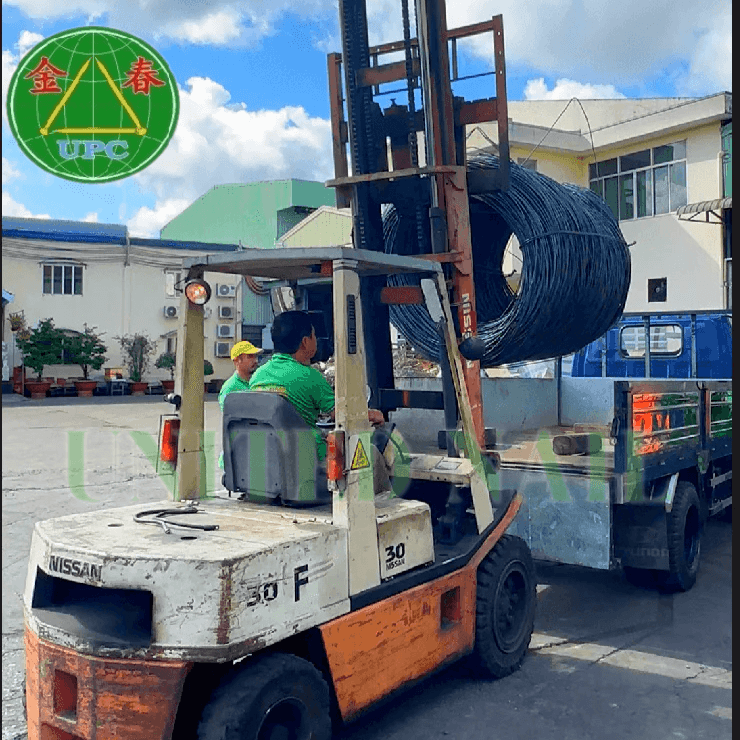

1. Sourcing the Best Raw Materials

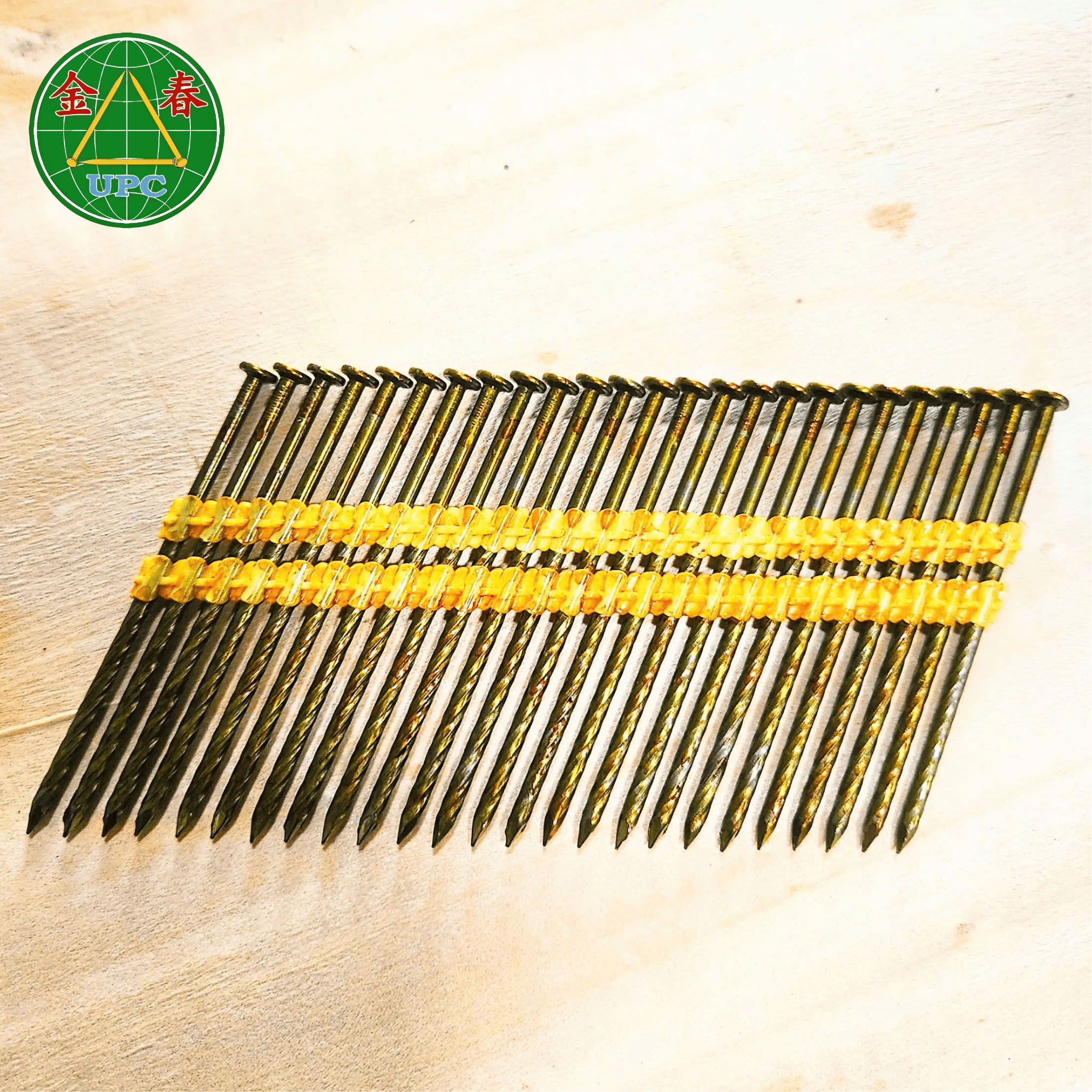

One of the first steps in creating top-tier plastic strip nails is selecting the appropriate raw materials. United Nail sources its materials from reputable suppliers who adhere to the highest industry standards. The steel used in the production of the nails is carefully chosen for its strength and resistance to corrosion, ensuring long-lasting performance. Meanwhile, the plastic used in the strips is specifically designed to be durable, heat-resistant, and flexible enough to withstand the impact of nail guns without breaking.

The selection of raw materials is crucial because the quality of the plastic strip nails ultimately depends on the strength and durability of both the steel nails and the plastic strips that hold them together. United Nail goes above and beyond to ensure that only the finest materials are used, resulting in a product that customers can trust.

2. Advanced Production Technology

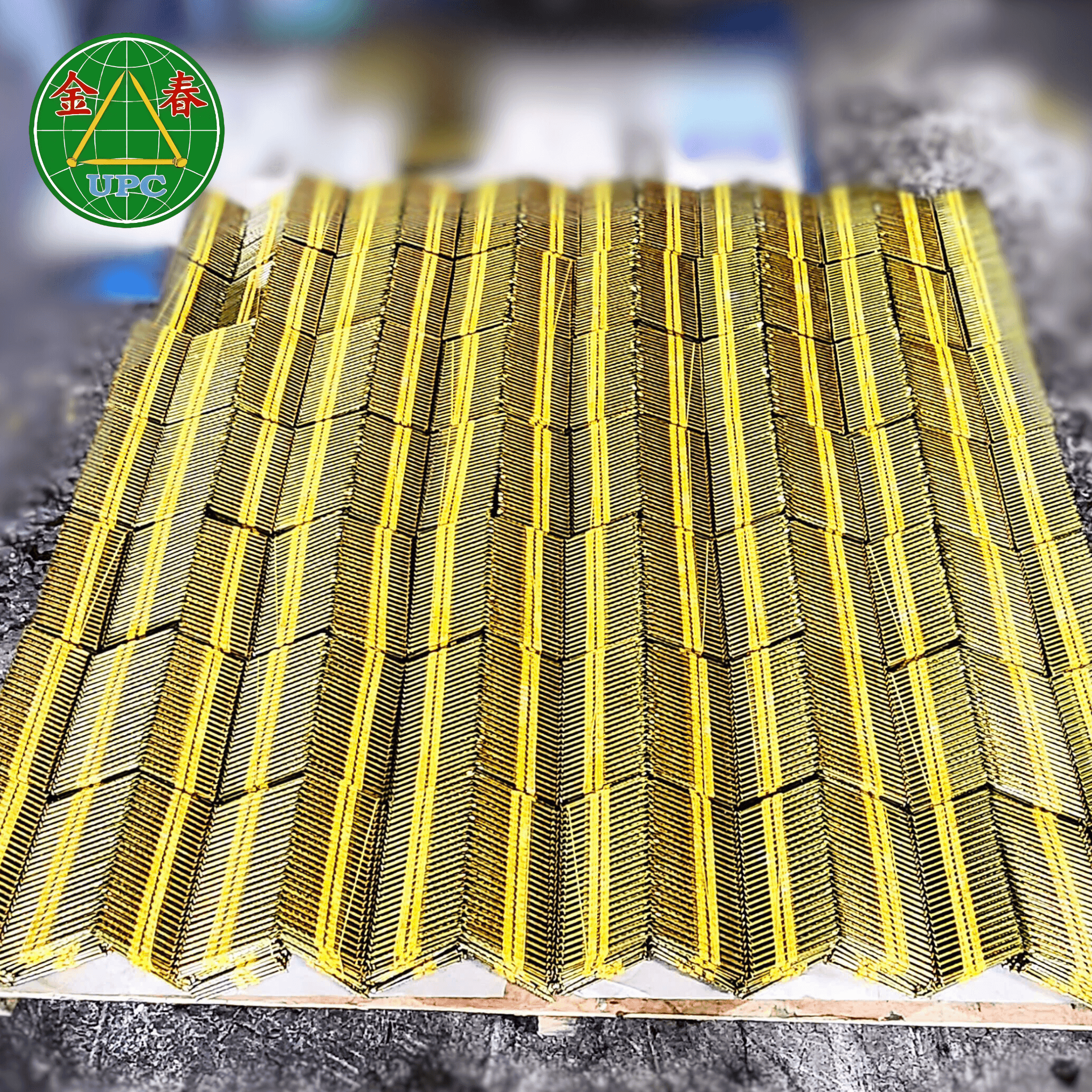

To produce high-quality plastic strip nails, United Nail employs state-of-the-art machinery and automation technology. Their manufacturing process is highly efficient, allowing them to produce large quantities of nails while maintaining strict quality control. Automation also reduces the risk of human error, ensuring that each plastic strip nail meets the company’s rigorous standards.

The production process begins by cutting steel wire into precise lengths and forming them into nails. These nails are then heat-treated to increase their strength and durability. Finally, the nails are assembled into strips using a durable plastic that holds them securely in place. The plastic strips are engineered to work seamlessly with a variety of nail guns, making them ideal for a wide range of applications in construction and manufacturing.

3. Strict Quality Control Procedures

See more genuine Plastic Strip Nails products via the link: https://unitednail.vn/en/danh-muc/others/

4. Innovation and Continuous Improvement

Sustainability in the Production of Plastic Strip Nails

In today’s world, sustainability is more important than ever. United Nail understands this and has made significant efforts to reduce the environmental impact of their production processes. One way they do this is by using recyclable materials in the plastic strips that hold their nails together. By opting for environmentally friendly plastics, United Nail not only reduces waste but also helps lower their carbon footprint.

Additionally, the company is committed to reducing energy consumption in their factories. They have implemented energy-efficient practices, such as using renewable energy sources and optimizing their machinery to reduce power usage during production. This not only helps protect the environment but also lowers production costs, allowing United Nail to offer competitively priced products to their customers.

Expanding into International Markets

United Nail’s journey to becoming a leading global supplier of plastic strip nails is marked by its expansion into international markets. The company has established a strong presence in regions like North America, Europe, and Asia, where their products are highly regarded for their quality and reliability. By working closely with distributors and clients across the globe, United Nail continues to grow its customer base and meet the diverse needs of construction professionals worldwide.

As they expand into new markets, United Nail maintains the same high standards that have made them successful. Their commitment to providing consistent quality, coupled with their ability to scale production, allows them to meet the demands of even the largest construction projects.

The Future of Plastic Strip Nails at United Nail

Looking ahead, United Nail is focused on continuing its legacy of excellence in the production of plastic strip nails. The company is dedicated to advancing its research and development efforts, finding new ways to improve the durability, efficiency, and sustainability of their products. They are also exploring new opportunities for collaboration with international partners, aiming to expand their reach even further into the global market.

Conclusion

The journey to create high-quality plastic strip nails at United Nail is a testament to the company’s dedication to innovation, sustainability, and customer satisfaction. From the careful selection of raw materials to the implementation of cutting-edge technology, every step of the production process reflects United Nail’s commitment to excellence. As the demand for plastic strip nails continues to grow, United Nail is well-positioned to lead the industry into the future, providing reliable and durable products to customers around the world.

UNITED NAIL PRODUCTS CO., LTD

Specializing in manufacturing high quality industrial nails and tie wire

Address: 16A8, Tra Noc Industrial Zone 1, Tra Noc Ward, Binh Thuy District, Can Tho City, VietNam

Phone: (+84) 986831838

Email: sales5@unitednail.com