United Nail Products Co., Ltd is a leading supplier of high-quality construction materials and industrial products in Vietnam. Our company is dedicated to providing innovative and reliable solutions to meet the demands of contractors, builders, and engineers in various construction projects. Over the years, we have built a reputation for delivering durable, cost-effective, and efficient products. Among our wide range of products, our Black Annealed Tie Wire 16GA 3.5 lbs, EG Smooth Coil Nails, and Common Nails have consistently been our top sellers, and for good reason. These products not only meet the stringent requirements of the construction industry but also offer superior performance, making them trusted choices for professionals in the field.

Let’s dive deeper into the features, applications, advantages, and potential drawbacks of these best-selling products offered by United Nail Products Co., Ltd.

MỤC LỤC BÀI VIẾT

Black Annealed Tie Wire 16GA 3.5 lbs

– is proud to be United Nail Products’ Best Selling High-Quality Construction Materials (The Backbone of Concrete Construction)

The Black Annealed Tie Wire 16GA 3.5 lbs by United Nail Products Co., Ltd is one of the essential products used in the construction industry. It is specifically designed for tying rebar, a fundamental task in reinforcing concrete structures. Made from high-quality carbon steel, the wire undergoes a specialized annealing process that improves its flexibility, making it easy to work with while ensuring maximum strength. This high level of flexibility is crucial for construction projects, as it allows workers to tie rebar securely and quickly, even in tight spaces.

The tie wire is compactly designed yet multifunctional, making it a reliable companion on construction sites.

Applications of Black Annealed Tie Wire

Black Annealed Tie Wire is used in a variety of applications across different sectors. Some of the most common uses include:

- Rebar Tying for Concrete Construction: The primary application of Black Annealed Tie Wire is in reinforcing concrete structures. It is used to tie steel reinforcement bars (rebar) together, ensuring the integrity and stability of the concrete.

- Steel Frame Installations: This tie wire is used to secure steel structures in large construction projects, such as high-rise buildings, bridges, and factories. The wire helps hold the steel frames in place during the construction process.

- Agricultural Uses: Beyond construction, Black Annealed Tie Wire is also widely used in agriculture, particularly for tying plants and vines in greenhouses or on farms.

- Architectural and Structural Supports: The wire is also used in securing various structural elements during the construction of buildings, roads, and other infrastructure projects.

Reinforcing concrete structures

Reinforcing concrete structures

Benefits of Black Annealed Tie Wire

- High Strength and Durability: The annealing process ensures that the wire is strong and resistant to breakage, even when used in demanding applications.

- Corrosion Resistance: Black Annealed Tie Wire is coated with a layer of protective material, which prevents rust and corrosion, even in harsh outdoor environments. This increases the lifespan of the wire and ensures that it performs well under various weather conditions.

- Ease of Use: Thanks to its flexibility and ease of manipulation, workers can tie rebar more efficiently and effectively, saving time and effort on the job site.

- Cost-Effective: Black Annealed Tie Wire offers excellent value for money, providing long-term performance without the need for frequent replacement.

Drawbacks of Black Annealed Tie Wire

- Limited Load Capacity: Although Black Annealed Tie Wire is highly durable and flexible, it may not be suitable for applications requiring very high tensile strength. For some heavy-duty tasks, stronger materials or thicker wires may be needed.

- Environmental Sensitivity: While it is corrosion-resistant, exposure to extremely harsh conditions, such as constant direct contact with highly acidic or alkaline environments, could lead to degradation over time.

- Manual Labor-Intensive: While the wire itself is easy to handle, it still requires significant manual labor to tie the rebar, which could slow down large projects or increase labor costs in some cases.

EG Smooth Coil Nails – Versatile and Reliable Fasteners

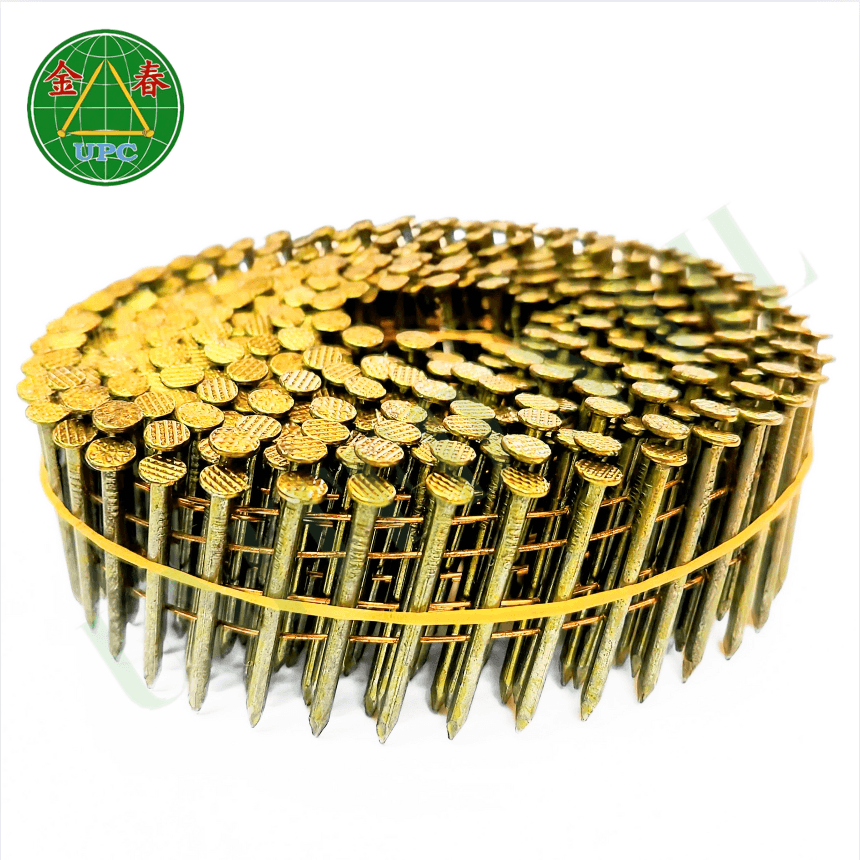

The EG Smooth Coil Nails from United Nail Products Co., Ltd are a preferred choice for various fastening applications in the construction and manufacturing industries. Unlike traditional straight nails, these nails come in a coil design, allowing for quick and efficient loading into automatic nail guns. This design not only saves time but also increases productivity, making it an ideal choice for large-scale projects.

The EG Smooth Coil Nails are made from high-quality steel and are coated with a layer of zinc through the electro-galvanization (EG) process, which provides excellent corrosion resistance. This feature makes them ideal for outdoor use, where exposure to the elements could otherwise lead to rust and degradation.

These nails come in a coil design, allowing for quick and efficient loading into automatic nail guns

Applications of EG Smooth Coil Nails

These nails are incredibly versatile and can be used in various applications across industries. Some common uses include:

- Wood Framing and Construction: EG Smooth Coil Nails are ideal for use in wood framing, including the assembly of wooden structures, roofing, and flooring. They can be used to fasten plywood, drywall, and other wood-based materials together.

- Steel Frame Construction: These nails are also effective in securing steel components in structural and industrial construction. They can be used in both residential and commercial projects, where strong, reliable fastening is needed.

- Door and Window Installation: The nails are perfect for securing door frames, window frames, and other structural components made of wood or steel. Their smooth surface prevents splitting and damage to the materials.

- Packaging Industry: EG Smooth Coil Nails are also used in the production of wooden pallets, crates, and packaging materials, where quick and reliable fastening is essential.

Benefits of EG Smooth Coil Nails

- Corrosion Resistance: The electro-galvanized coating ensures the nails remain free from rust and corrosion, even when exposed to moisture or outdoor environments.

- Increased Productivity: The coil design allows for fast loading into nail guns, improving efficiency and reducing the time needed for installation. This is particularly beneficial in large-scale construction projects where speed is critical.

- Durability and Strength: The nails are made from high-quality steel, ensuring they have high tensile strength and can withstand heavy-duty applications.

- Aesthetic Appeal: The smooth, shiny finish of the nails ensures that they look neat and professional when used in exposed areas of a construction project.

Drawbacks of EG Smooth Coil Nails

- Compatibility Issues with Some Nail Guns: While they work well with most automatic nail guns, some lower-end models may struggle with loading or driving the coil nails effectively. This could slow down work processes or require manual intervention.

- Cost Compared to Standard Nails: EG Smooth Coil Nails are generally more expensive than traditional nails, particularly for small-scale projects. However, the price difference is often justified by the time savings and enhanced performance for large construction tasks.

- Limited Use in Certain Materials: These nails may not be suitable for very hard materials like dense hardwood or thick metal, where specialized fasteners might be required.

Common Nails – A Staple in the Construction Industry

Common Nails from United Nail Products Co., Ltd are a basic yet indispensable tool in the construction industry. These nails are designed to be used for a wide range of applications, from basic construction tasks to more specialized jobs. They are commonly used in projects where strength and reliability are required, making them a trusted choice for both residential and commercial construction.

Made from high-quality steel, Common Nails are available in various sizes and lengths, making them suitable for different types of materials, including wood, metal, and plastic. The nails are designed to penetrate and hold materials together securely, ensuring that structures remain stable and durable.

Yellow Plated Nails 2.06×35| Common Nail

Applications of Common Nails

Common Nails are extremely versatile and are used in various construction, manufacturing, and household applications, such as:

- Basic Construction: Common Nails are used for general woodwork, including framing, sheathing, and finishing. They are essential in building wooden structures like houses, sheds, and fences.

- Furniture and Cabinet Making: These nails are used in the furniture industry for assembling wooden furniture, cabinets, and other wood-based products.

- Packaging and Shipping: In the packaging industry, Common Nails are used to fasten wooden crates, pallets, and other packaging materials, providing a secure and sturdy structure for transporting goods.

- DIY Projects: Common Nails are also popular among DIY enthusiasts for small home improvement projects, repairs, and woodworking tasks.

Benefits of Common Nails

- Strong and Reliable: Common Nails provide a strong bond between materials, ensuring that the structure holds up over time without the risk of loosening or breaking.

- Ease of Use: These nails are easy to handle and can be driven into most materials with minimal effort, making them a popular choice for both professional contractors and DIY enthusiasts.

- Cost-Effective: Common Nails are inexpensive and offer great value for money, making them an economical choice for a wide variety of construction tasks.

- Long-Lasting Performance: Made from durable steel, these nails are built to last and are ideal for both indoor and outdoor use, depending on the coating.

Drawbacks of Common Nails

- Prone to Rusting: If not coated or treated, Common Nails can be susceptible to rust, especially when exposed to moisture. This can impact the durability and strength of the connection over time.

- Potential for Splitting Wood: When driven into certain types of wood, especially softwood, Common Nails can cause the wood to split. Proper care and pilot holes may be needed to prevent this issue.

- Limited Use for Heavy-Duty Applications: For particularly heavy-duty projects or tasks requiring very high tensile strength, Common Nails may not be suitable, and specialized fasteners may be necessary.

Conclusion

United Nail Products Co., Ltd is proud to offer a diverse range of high-quality products that meet the needs of the construction industry. Our top three best-selling products — Black Annealed Tie Wire 16GA 3.5 lbs, EG Smooth Coil Nails, and Common Nails — are trusted by contractors, builders, and engineers for their exceptional performance, durability, and value. Whether you’re working on large-scale construction projects, home improvement tasks, or industrial manufacturing, these products are designed to help you complete your work efficiently and effectively.

However, it’s important to carefully consider the specific needs of your project and the environment in which these products will be used. Understanding both the benefits and limitations of each product will help ensure that you make the best choice for your construction requirements.

For high-quality construction materials, look no further than United Nail Products Co., Ltd. Contact us today to learn more about our products and how we can support your next project.

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production

Thank you for taking the time to read this article. We hope the information proves helpful to you.