In the bustling industrial heart of Vietnam, where factories pulse with the rhythm of global trade, a quiet revolution is reshaping the logistics industry. Pallets, the backbone of shipping, carry everything from electronics to fresh produce across oceans, but their environmental cost is steep. At United Nail Products Co. Ltd, our eco-friendly pallet nails specifically, Coil nails are transforming this landscape. These fasteners are not just tools for assembling wooden crates; they are champions of sustainability, reducing waste, boosting efficiency, and aligning with the global push for greener supply chains. This article explores how our Coil nails are redefining pallet manufacturing, empowering businesses to meet international demands while building a legacy of environmental responsibility.

MỤC LỤC BÀI VIẾT

Why Eco-Friendly Pallet Nails Are Critical for Sustainable Logistics

The logistics sector is a cornerstone of global commerce, moving billions of goods annually. Yet, it faces a significant challenge: its environmental footprint. Wooden pallets, essential for transporting goods, are often discarded after a single use, contributing to deforestation and landfill overflow. Industry data suggests that over 2 billion pallets are used worldwide each year, with millions ending up as waste. Inefficient fastening methods worsen the problem, low-quality nails cause pallets to fail during shipping, leading to damaged goods and increased scrap. Over-nailing, a common practice with substandard fasteners, consumes excess materials and energy, further straining resources.

Pallets made from poor quality wood are also one of the main reasons why pallets are easily damaged.

United Nail’s Coil nails, designed as eco-friendly pallet nails, address these issues head-on. Engineered for precision and durability, they minimize waste, enhance pallet strength, and support recyclable designs. By choosing our Coil nails, manufacturers can reduce their environmental impact while ensuring pallets meet the rigorous standards of international markets, from Vietnam’s busy ports to destinations like the United States, Japan, Australia, and Thailand. These nails are a small but powerful step toward a more sustainable logistics industry.

The Strength of Eco-Friendly Pallet Nails: Why Coil Nails Excel

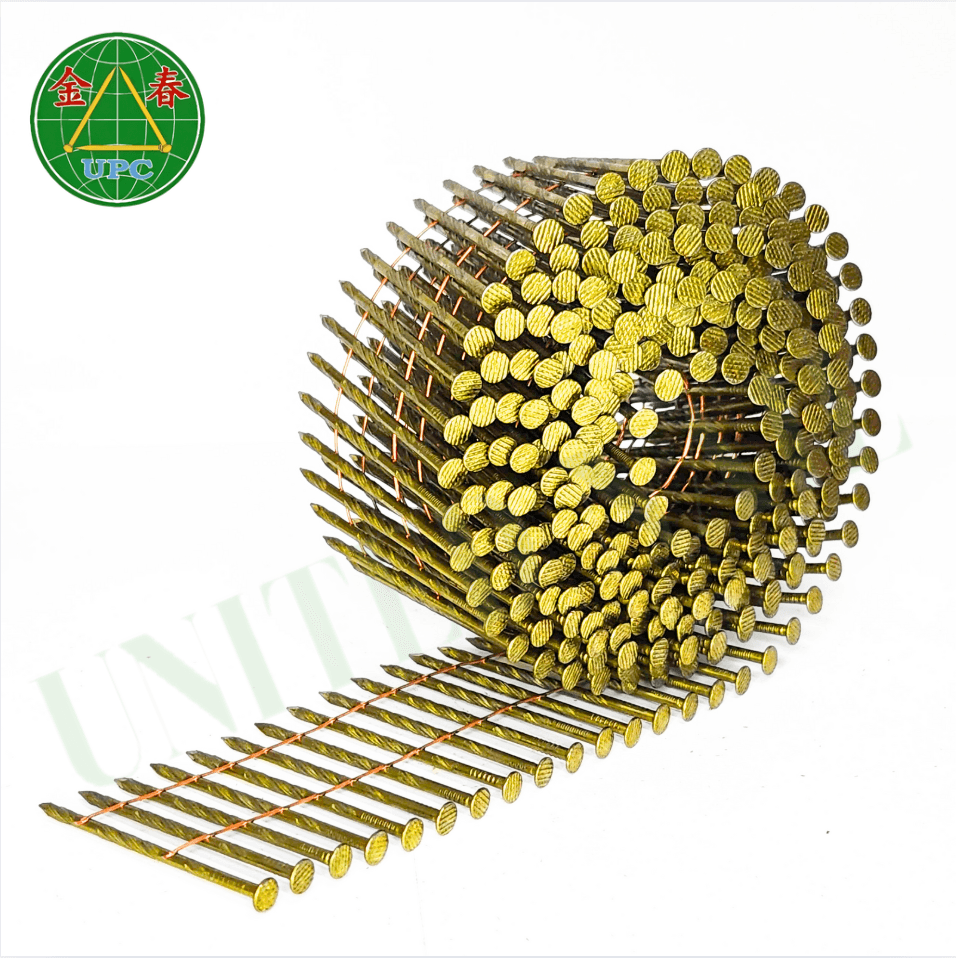

Our Coil nails are crafted with sustainability and performance at the core, making them the preferred choice for pallet manufacturing. Here’s what sets them apart as eco-friendly pallet nails:

- Precision to Reduce Waste: Delivered in tightly wound coils, our nails ensure accurate placement with pneumatic nail guns, minimizing misfires and wood damage. Factories using our nails report up to 25% less scrap, preserving valuable timber resources.

- Automation for Efficiency: Compatible with high-speed automated systems, Coil nails streamline pallet assembly, cutting energy use and labor costs by up to 20% compared to traditional manual nailing methods.

- Export-Ready Durability: Built to comply with ISPM 15 standards for heat-treated pallets, our nails ensure pallets withstand rough handling, long sea voyages, and diverse climates without compromising environmental goals.

- Corrosion Resistance: Featuring advanced galvanized or stainless-steel coatings, our nails resist rust, extending pallet lifespan and reducing the need for frequent replacements.

2.1mmx32mm Coil Nails

- Versatile Design: Available in lengths from 1.5 to 3 inches and various shank types (smooth, ring, or screw), our nails suit a range of wood types and pallet configurations, from lightweight crates to heavy-duty export pallets.

United Nail is proud to offer a wide variety of dimension nails to cater to the diverse needs of the nail gun market.

These features make our Coil nails a cornerstone of eco-friendly logistics, enabling businesses to produce pallets that are both robust and planet-friendly.

A Story of Green Transformation: Hanh’s Mission

Hanh, a factory supervisor in Binh Duong, Vietnam, manages a production line crafting pallets for a major exporter of organic tea. Her company recently committed to achieving carbon-neutral operations by 2030, a bold goal that put pressure on every aspect of production. However, outdated fastening methods were a major hurdle. Workers relied on manual nails, which led to frequent misfires, damaged wood, and excessive waste—nearly 30% of their timber was scrapped monthly. The inefficiency slowed output, and the environmental toll clashed with the company’s sustainability pledge. Hanh felt the weight of balancing export deadlines with her team’s green ambitions.

Everything changed when Hanh’s team adopted United Nail’s Coil nails, engineered as eco-friendly pallet nails. Equipped with pneumatic nail guns, the team doubled their output, assembling 500 pallets daily with 25% less wood waste. The nails’ precision eliminated errors, and their durability ensured pallets endured long journeys to Japan and Europe without failing. Hanh’s factory earned a sustainability certification, and her success inspired other manufacturers in the region. These eco-friendly pallet nails didn’t just build pallets—they built a vision of a greener future, proving that small innovations can drive industry-wide change.

Maximizing Eco-Friendly Pallet Nails: Best Practices for Manufacturers

To unlock the full potential of eco-friendly pallet nails, manufacturers can adopt these best practices:

- Invest in High-Quality Tools: Use pneumatic nail guns designed for Coil nails to ensure smooth operation and prevent jams. Regular maintenance, such as cleaning and lubricating the guns, sustains performance and extends tool lifespan.

- Choose the Right Nail Specifications: Select nail lengths (e.g., 1.5–2.5 inches) and shank types based on wood thickness and pallet type. For example, ring-shank nails offer extra grip for softwoods, while screw-shank nails excel in hardwoods.

- Train for Precision and Safety: Educate workers on proper nail gun techniques, including maintaining consistent pressure and angle, to maximize accuracy and minimize material loss. Safety training is also critical to prevent accidents.

- Source Sustainable Materials: Pair Coil nails with certified sustainable timber, such as FSC-certified wood, to enhance your pallets’ eco-credentials and appeal to environmentally conscious clients in markets like Europe and Australia.

FSC Certificate contributes to protecting the environment and natural ecosystems.

The strict operating principles of this NGO not only protect natural forest timber resources but also protect water resources and the atmosphere.

5. Implement Quality Control: Regularly inspect pallets during production and after shipping to ensure nails maintain strength. Use data from inspections to refine processes, optimize nail usage, and further reduce waste.

By following these steps, manufacturers can maximize the efficiency and sustainability benefits of eco-friendly pallet nails, creating pallets that are both high-performing and environmentally responsible.

The Global Reach of Eco-Friendly Pallet Nails

The global shift toward sustainability is transforming industries, and eco-friendly pallet nails are leading the charge in logistics. By reducing waste and energy use, our Coil nails help manufacturers lower their carbon footprint, aligning with initiatives like the United Nations’ Sustainable Development Goals. In Japan, where strict environmental regulations govern imports, our nails enable exporters to meet compliance standards while maintaining efficiency. In Australia, they support the growing demand for recyclable pallets in agriculture and retail. In Thailand, local manufacturers use our nails to compete in global markets, leveraging Vietnam’s strategic position as a manufacturing hub.

United Nail’s commitment to sustainability goes beyond our products. Our manufacturing facilities in Vietnam use energy-efficient processes, and we partner with suppliers who prioritize sustainable sourcing. We also invest in research to develop even more eco-friendly coatings and designs, ensuring our nails remain at the forefront of green innovation. By choosing our eco-friendly pallet nails, businesses are not just investing in quality, they’re joining a global movement to protect the planet for future generations.

Real-World Impact: Case Studies of Eco-Friendly Pallet Nails

The impact of eco-friendly pallet nails extends across industries and borders. Consider a fruit exporter in Vietnam shipping mangoes to Canada. By using United Nail’s Coil nails, the exporter reduced pallet failures by 15%, saving thousands of dollars in damaged goods. In Italy, a furniture manufacturer adopted our nails for crate production, cutting wood waste by 20% and earning praise from eco-conscious consumers. These success stories highlight the tangible benefits of eco-friendly pallet nails, from cost savings to enhanced brand reputation.

In Vietnam, small and medium-sized enterprises are also reaping the rewards. A family-owned factory in Ho Chi Minh City switched to our Coil nails and saw a 30% increase in production speed, allowing them to secure contracts with Australian importers. These examples demonstrate how eco-friendly pallet nails are leveling the playing field, enabling businesses of all sizes to compete globally while prioritizing sustainability.

Partner with United Nail for a Greener Tomorrow

At United Nail Products Co. Ltd, we believe that sustainability starts with small, purposeful choices. Our Coil nails, crafted as eco-friendly pallet nails, empower manufacturers to build pallets that are strong, sustainable, and ready for the global stage. From Hanh’s factory in Binh Duong to exporters worldwide, our nails are driving a greener logistics industry. Whether you’re shipping tea to Tokyo, mangoes to Toronto, or electronics to Sydney, United Nail is your partner in building a sustainable future.

Contact us today to request a quote, order samples, or learn how our eco-friendly pallet nails can transform your operations. Together, let’s create a world where every pallet carries the promise of a healthier planet.

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production

Thank you for taking the time to read this article. We hope the information proves helpful to you.