In the construction and manufacturing industries, construction nails are not merely tools but the core elements that ensure strength, durability, and safety for every project. From traditional wooden houses in rural Vietnam to modern high-rise buildings in urban centers, construction nails serve as invisible yet indispensable “connectors.” At United Nail Products Co. Ltd, a leading supplier in Vietnam, we take pride in offering high-quality products such as coil nails, common nails, and plastic strip nails, catering to a wide range of needs—from large-scale projects to small-scale craftsmanship.

This article delves deeply into each type of nail, analyzing their characteristics, applications, advantages, and disadvantages, while providing valuable insights into nail selection, production processes, and trends in Vietnam’s construction nail market. Let’s explore in detail to better understand the critical role of construction nails in daily life and industry!

MỤC LỤC BÀI VIẾT

What Are Construction Nails? Their Role in Life and Industry

Construction nails are metal products designed to fasten and connect materials such as wood, metal, concrete, plastic, or even modern composite materials. Typically made from steel—a material renowned for its high strength and load-bearing capacity—nails can be coated with finishes like galvanization, electrostatic paint, or crafted from stainless steel to enhance corrosion resistance, depending on their intended use.

The Role of Construction Nails

- Material Connection: Nails secure components within a structure, from wooden frames and partitions to interior fittings.

- Enhanced Durability: A high-quality nail can withstand tensile forces, compression, and environmental impacts, ensuring long-lasting structures.

- Support for Mass Production: In industries like woodworking, packaging, or assembly, construction nails accelerate progress and boost efficiency.

In Vietnam—a country with a tropical monsoon climate characterized by high humidity, frequent rain, and constant weather changes—the demand for construction nails is particularly stringent. High moisture levels necessitate nails with superior rust resistance. This is precisely why United Nail Products Co. Ltd continually focuses on improving our products to suit local conditions.

Coil Nails – The Optimal Solution for Industrial Production

What Are Coil Nails?

Coil nails are specially designed for use with pneumatic nail guns. They are arranged in circular coils, connected by thin steel wire or specialized adhesive, forming a continuous strip. Each coil can contain anywhere from 150 to 350 nails—or even thousands for smaller sizes—depending on the dimensions and intended application.

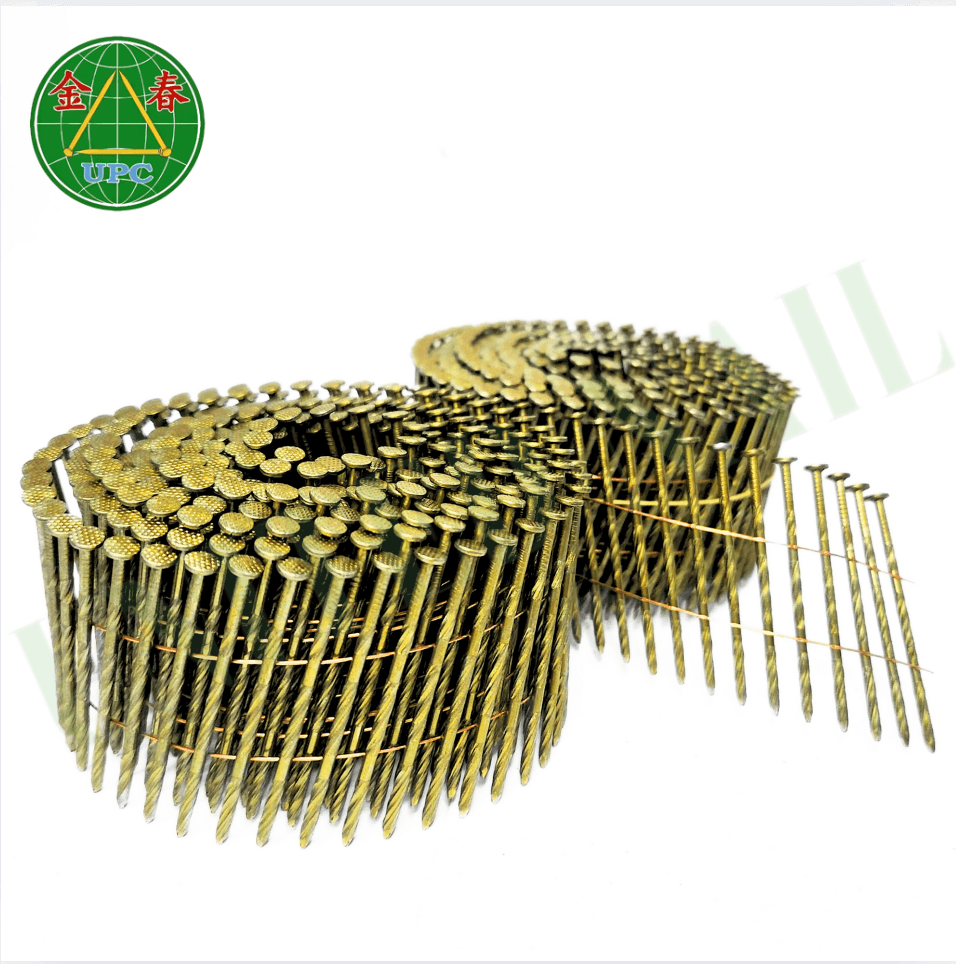

2.3mm x 45mm Coil Nails

Technical Specifications of Coil Nails

- Material: Galvanized carbon steel, stainless steel, or alloy steel.

- Size: Ranging from 25mm to 100mm, with shank diameters from 2.1mm to 3.3mm.

- Coating: Hot-dip galvanized, electro-galvanized, or rust-proof painted.

- Primary Applications: Manufacturing wooden pallets, export crates, prefabricated house frames, and projects requiring high-speed construction.

Production Process of Coil Nails

To produce high-quality coil nails, United Nail Products Co. Ltd employs modern production lines with the following steps:

- Steel Cutting: Steel wire is cut into segments based on desired sizes.

- Shaping: Nail heads are flattened, and tips are sharpened to enhance penetration.

- Galvanizing: Nails are dipped in hot zinc baths or processed via electro-galvanization.

- Coiling: Nails are joined with wire or adhesive and rolled into compact coils.

Advantages of Coil Nails

- High Construction Speed: Paired with a nail gun, a single coil can complete hundreds of fastenings in minutes, far surpassing manual methods.

- Precision: Coil nails are engineered for seamless compatibility with nail guns, minimizing jams or misfires.

- Economic Efficiency: Though initially more expensive than common nails, coil nails save significant labor and time costs, especially in large projects.

- Superior Durability: The galvanized coating protects against corrosion, making them ideal for Vietnam’s humid climate.

Disadvantages

- Coil nails require specialized nail guns, making them less suitable for small-scale tasks or projects without supporting equipment.

Real-World Applications of Coil Nails in Vietnam

Vietnam ranks among the world’s top exporters of wood and wood products. Businesses in woodworking hubs like Dong Nai, Binh Duong, and Quang Nam rely heavily on coil nails to produce pallets and crates for export to markets such as the US, EU, and Japan. In construction, coil nails are used to assemble wooden house frames, secure formwork, or reinforce temporary structures during building processes.

Specific Example

A customer from Binh Duong shared: “We used to spend an entire day hammering hundreds of pallets with common nails. Since switching to coil nails and nail guns, our productivity has increased fivefold, and the joints are even stronger. United Nail’s products are truly reliable!”

Common Nails – Simplicity Rooted in Tradition

What Are Common Nails?

Common nails are the most basic and time-honored type of construction nail, typically driven manually with a hammer. Featuring a simple design with a round shank, flat head, and pointed tip, they are a familiar sight in every Vietnamese household—from traditional carpenters in craft villages to small-scale construction sites.

2.06mm x 35mm Common Nail

Technical Specifications of Common Nails

- Material: Low-carbon steel, galvanized steel, or stainless steel.

- Size: Ranging from 20mm (small nails) to 150mm (large nails), with shank diameters from 1.5mm to 6mm.

- Surface: Smooth or twisted with grooves for enhanced grip in hardwoods.

- Applications: Crafting furniture, building houses, constructing fences, or performing simple repairs.

Production Process of Common Nails

- Raw Material: Steel wire is sourced from reputable suppliers, ensuring optimal hardness and flexibility.

- Cutting and Shaping: Automated machines cut the wire into uniform segments, then flatten the heads and sharpen the tips.

- Surface Treatment: Nails are galvanized or polished to improve aesthetics and rust resistance.

- Packaging: Common nails are packed in batches ranging from 1kg to 50kg for easy transport and use.

Advantages of Common Nails

- Ease of Use: No specialized tools are required—just a hammer suffices.

- Low Cost: These are the most affordable nails, ideal for budget-conscious projects.

- Versatility: Suitable for a wide range of tasks, from construction and repairs to artisanal crafts.

- Availability: Common nails are widely accessible at hardware stores across Vietnam.

Disadvantages

- Construction speed is slower, they are prone to rust if uncoated, and they may struggle with hardwoods or thick materials.

Real-World Applications of Common Nails in Vietnam

In traditional craft villages like Chang Son (Hanoi) or Phu Vinh (Binh Duong), common nails remain the go-to choice for crafting tables, chairs, cabinets, or intricate wooden artworks. In residential construction, they are used to build fences, secure formwork, or assemble basic wooden structures. Particularly in rural Vietnam, common nails are an essential household item.

Specific Example

A carpenter from Phu Vinh village said: “I use United Nail’s common nails to craft export-grade chairs. The galvanized finish ensures durability and prevents rust, maintaining product quality for international customers.”

Plastic Strip Nails – A Breakthrough in Construction Technology

What Are Plastic Strip Nails?

Plastic strip nails are arranged in straight strips, held together by a sturdy plastic band. Designed for use with specialized nail guns, they offer high-speed construction and excellent finish quality. After being driven, the plastic strip breaks away cleanly, leaving no residue on the material surface, making them ideal for projects requiring aesthetic precision.

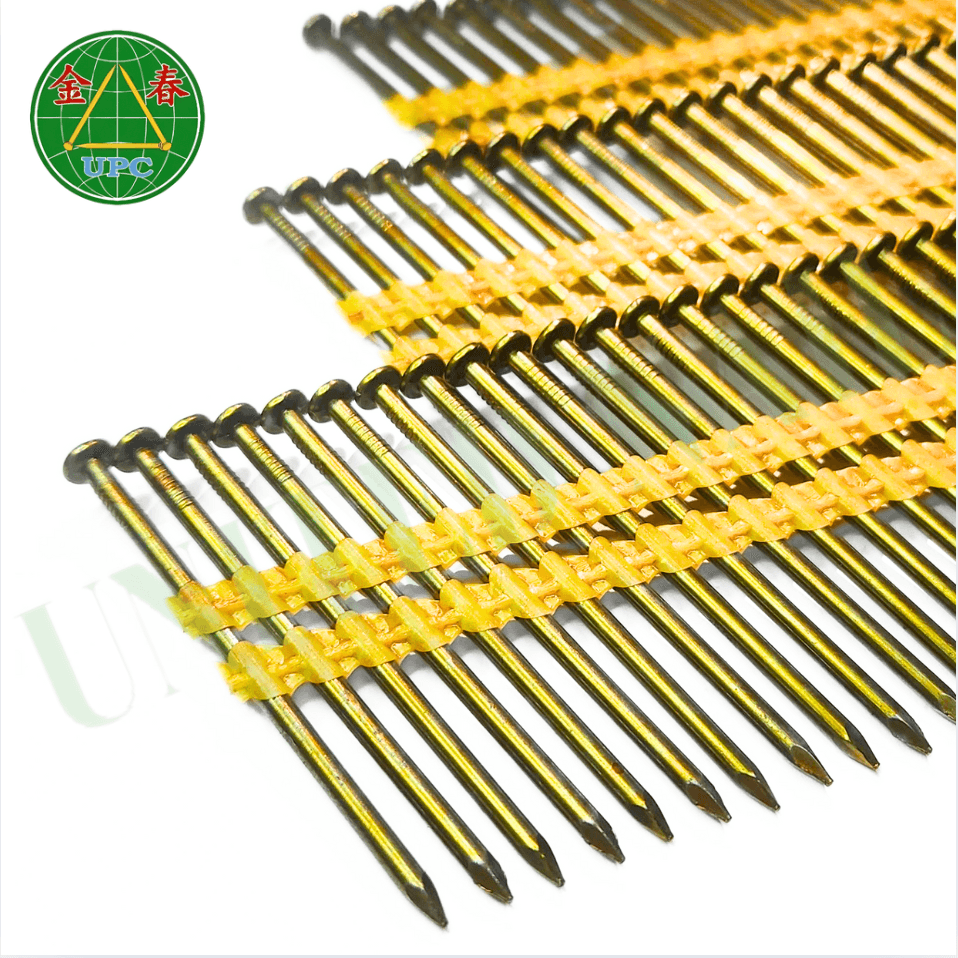

3.3mm x 76mm Plastic Strip Nails

Technical Specifications of Plastic Strip Nails

- Material: Galvanized steel or stainless steel, paired with high-quality ABS or composite plastic.

- Size: Typically 50mm to 100mm, with shank diameters from 2.8mm to 3.8mm.

- Quantity: Each strip holds 20 to 40 nails.

- Applications: Assembling steel house frames, securing floorboards, or producing premium furniture.

Production Process of Plastic Strip Nails

- Nail Production: Nails are cut, shaped, and galvanized similarly to other types.

- Plastic Strip Assembly: Nails are aligned in molds and bonded with molten plastic strips.

- Quality Inspection: Each strip is tested for durability and compatibility with nail guns.

- Packaging: Plastic strip nails are boxed in small units for convenient transport and storage.

Advantages of Plastic Strip Nails

- Aesthetic Finish: Leaves no plastic traces, perfect for projects requiring a clean surface.

- High Efficiency: Rapid firing speeds minimize construction time.

- Durability: Galvanized coating and quality plastic ensure rust resistance and strength.

- Ease of Use: The plastic strip prevents nails from scattering during loading, ensuring smooth operation.

Disadvantages

- Higher cost compared to common nails and the need for specialized equipment.

Real-World Applications of Plastic Strip Nails in Vietnam

In modern steel-framed house projects—a growing trend in Vietnam—plastic strip nails are used to fasten wooden panels or floorboards. In the premium furniture sector, they ensure seamless joints, meeting the stringent standards of European and American markets.

Specific Example

A contractor in Ho Chi Minh City noted: “We used United Nail’s plastic strip nails to assemble frames for a resort project in Phu Quoc. The speed was impressive, and the finish was flawless—our clients were thrilled.”

How to Choose the Right Construction Nails for Your Project

To select the appropriate nail type, consider these factors:

- Purpose: Coil nails for mass production, common nails for manual work, and plastic strip nails for modern construction.

- Material: Softwood, hardwood, metal, or concrete each requires a specific nail type.

- Environment: For outdoor or humid conditions, opt for galvanized or stainless steel nails.

- Budget: Common nails are cost-effective, while coil and plastic strip nails suit high-efficiency, large-scale projects.

United Nail Products Co. Ltd is always ready to assist you in choosing the best product for your needs!

Trends in Construction Nail Usage in Vietnam

- Technological Adoption: The rise of nail guns has boosted demand for coil nails and plastic strip nails.

- Wood Export Growth: High-quality nails, especially coil nails, are in demand to meet international export standards.

- Green Construction: Eco-friendly, recyclable nails are emerging as a new trend.

Why Choose United Nail Products Co. Ltd?

- Top Quality: Our products meet ISO standards, satisfying rigorous international requirements.

- Diverse Options: From traditional common nails to modern coil and plastic strip nails.

- Dedicated Service: Our technical support team and nationwide delivery ensure customer satisfaction.

- Sustainable Value: We commit to delivering durable, high-quality, cost-effective products.

Conclusion

Construction nails are more than just products—they are the “heart” of every project and production process. Coil nails offer speed and efficiency, common nails uphold traditional versatility, and plastic strip nails symbolize modern innovation. With United Nail Products Co. Ltd as your partner, you’ll always find the perfect solution for your needs. Contact us today to learn more about our high-quality nails and receive expert advice!

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production

Thank you for taking the time to read this article. We hope the information proves helpful to you.