MỤC LỤC BÀI VIẾT

Introduction – Why 2 inch Coil Nails Became the Global Standard for Roofing & Construction

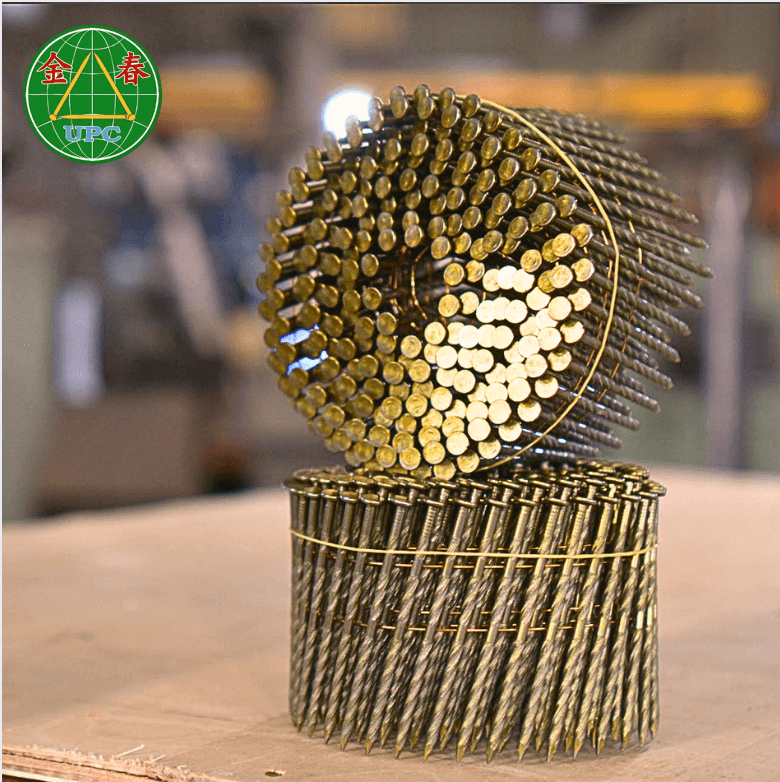

When construction crews from Florida to the Philippines choose fastening materials for roofing, framing, siding, or pallet manufacturing, one specification shows up more consistently than anything else: 2 inch Coil Nails. Whether smooth shank, screw shank, or ring shank, and whether paired with a checkered head or flat head, the 2 inch coil format has quietly become the industry benchmark for speed, reliability, and structural performance.

But the real advantage comes not simply from the nail length. It’s the combination of 9000 (300 nailsx30 boxes) nails per boxes, compatible shank types, optimized head designs, and the seamless integration with modern pneumatic coil nailers that make this configuration the “best choice” for contractors worldwide.

Imagine a roofing crew standing on a 600 m² warehouse at noon, the sun beating at 38°C, with thunderclouds forming at the horizon. In situations like this, efficiency isn’t a luxury—it’s survival. The ability to fire 5–7 nails per second for uninterrupted installation can decide whether a roof withstands high winds or gets compromised before the next storm season.

➡️ And this is exactly where 2 inch Coil Nails dominate the game.

They combine:

Speed: 300 nails per coil → reduces reload cycles dramatically

Versatility: available in screw, smooth, and ring shank

Strength: steel body with optimized tensile load

Precision: checkered or flat head depending on application requirements

Tool compatibility: fits most CN55–CN70 pneumatic coil nailers

Across manufacturing plants, logistics centers, shipping yards, agriculture storage, and housing projects, these nails solve a problem that crews everywhere understand: how to fasten materials quickly, safely, and permanently—even under extreme environmental conditions.

🌩️ Whether anchoring roofing sheets against tropical storms or assembling industrial pallets for 40-foot containers, the stability delivered by 2 inch Coil Nails is proven across hundreds of real-world scenarios.

What Exactly Makes 2 inch Coil Nails Special? — A Deep Dive Into the 9000pcs Set

To appreciate why contractors increasingly choose 2 inch Coil Nails, we must look beyond the surface. At first glance, a coil nail is a simple piece of steel wire shaped, cut, coiled, and collated. But modern coil nails are far from basic. Each nail goes through precision processes involving metallurgy, tension calibration, shank profiling, and automated collation techniques.

Let’s break down the four configurations available in this 9000pcs set:

🎯 A. Smooth Shank – The Speed King

The smooth shank version is engineered for:

Maximum firing speed

Minimal jamming

Clean penetration

With friction kept low, smooth shank 2 inch Coil Nails glide effortlessly through roofing sheets, plywood, OSB panels, and thin metal surfaces.

🔧 Ideal for:

Large-area roofing

Fence assembly

Multi-layer sheet installations

Subfloor underlayment

The smooth design also reduces wear on the pneumatic nailer’s driver blade, extending the lifespan of the tool.

🎯 B. Screw Shank – The Anti-Uplift Champion

Screw shank nails twist into material just like a screw, creating a mechanical lock that resists forces trying to pull the material apart.

This makes them perfect for:

High-wind regions

Materials prone to expansion/contraction

Wooden structures exposed to vibration

A 2 inch screw shank coil nail can deliver 30–50% more withdrawal resistance compared to a smooth shank version.

🎯 C. Ring Shank – The Grip Master

Ring shank nails feature ridges around the shank, creating a friction lock that prevents loosening.

Perfect for:

Pallet manufacturing

Crate assembly

Sheathing panels

Framing jobs where movement is expected

Each ridge increases surface contact, making the nail incredibly reliable for long-term applications.

🎯 D. Checkered Head vs. Flat Head – Choosing the Right Type

Depending on job requirements, crews can choose:

Checkered Head → improved holding power, reduces slippage when struck

Coil nails with checkered head

Flat Head → ideal for smooth surface finishes, reduces marking

Coil nails with flat head

In demanding tasks such as roofing or siding, head geometry is often overlooked—but it directly influences structural performance.

Why Roofing Contractors Prefer 2 inch Coil Nails for Metal Sheet, Asphalt Shingle & Tile Roofing

Roofing is a unique field in construction because mistakes are not just inconvenient—they are catastrophic. Water leakage, wind uplift, corrosion, and structural weakness can cost tens of millions of VND in damage per project.

Here’s why 2 inch Coil Nails are the default choice on job sites:

⏩ 1. Optimized Length for Penetration & Holding Strength

The 2 inch (≈50mm) length hits the sweet spot:

Long enough to secure roofing sheets to wooden or steel frames

Short enough to avoid punching through or cracking materials

This creates an ideal fastener-to-substrate ratio for:

Metal roofing

Asphalt shingles

Composite tiles

Fiber cement sheets

⏩ 2. Compatible with CN55–CN70 Pneumatic Coil Nailers

A roofing crew typically fires 10,000–20,000 nails per day. Using a coil compatible with most standard nailers:

Speeds up workflow

Reduces tool switching

Minimizes downtime

A single coil can contain 200–350 nails depending on wire gauge and collation angle.

⏩ 3. Weather-Resistant for Coastal & Humid Regions

With optional:

Electro-galvanized

Hot-dip galvanized

Stainless-coated

Vinyl-coated

2 inch Coil Nails withstand:

Salt spray

High humidity

Tropical UV exposure

Heavy rainfall

⛈️ In regions like Da Nang, Miami, Cebu, and Queensland, these nails are essential for resisting 100–150 km/h winds.

Industrial Applications of 2 inch Coil Nails — From Roofing to Pallet Factories

Although many people associate 2 inch Coil Nails primarily with roofing, real-world usage spans across dozens of industries. This versatility is one of the main reasons why global buyers prefer this nail size over many others. The 2-inch format works extremely well for medium-thickness materials, structural fastening, and repetitive high-volume production lines.

Let’s explore where these 9000pcs coil nail sets deliver the most value.

🏗️ A. Construction & Framing

In general construction work, workers need fasteners that won’t loosen when the building expands, contracts, or vibrates over time. The 2 inch length is strong enough to secure:

OSB, plywood, MDF panels

Wall sheathing

Interior framing

Subfloor layers

Temporary structures and scaffolding planks

The smooth, screw, and ring shank options allow builders to choose different holding strengths depending on vibration levels and load requirements.

Ring shank = permanent grip

Screw shank = best resistance for dynamic loads

Smooth shank = speed and efficiency

Homes built using these nails show better structural tightness, which directly contributes to energy efficiency and noise reduction.

🏭 B. Pallets, Crates & Industrial Packaging

Pallet manufacturing is one of the largest consumers of coil nails globally. A typical pallet factory produces 1,000–5,000 pallets per day, requiring consistent and reliable fasteners. The 2 inch Coil Nail fits perfectly into most pallet nailing patterns.

These nails excel in this sector because:

Ring shank provides high withdrawal resistance

2 inch length fits most 2-way and 4-way pallet designs

Steel durability prevents nail breakage during forklift lifting

Coils enable non-stop nailing—perfect for automated lines

Large exporters of seafood, agriculture, and electronics (such as in Vietnam, Thailand, and Mexico) rely heavily on pallets fastened with 2 inch coil nails to survive long international shipping journeys inside containers.

🚢 C. Marine, Coastal & Outdoor Projects

Salt spray, moisture, and strong winds make coastal construction highly demanding. Builders prefer nails that are:

Rust-resistant

Shock-resistant

Able to anchor materials exposed to storms and waves

With optional hot-dip galvanized or stainless coating, 2 inch Coil Nails last significantly longer in coastal climates compared to traditional loose nails.

Applications include:

Boat sheds

Coastal homes

Beach piers

Seaside warehouses

Saltwater-treated wood structures

This explains why tropical regions with frequent typhoons choose 2 inch coil nails as standard fastening materials.

🚚 D. Logistics, Warehouses & Manufacturing Plants

Large distribution centers often build structures that need rapid assembly and disassembly, such as:

Shelving systems

Modular partitions

Wooden packaging

Loading docks

Crates for machinery export

In these environments, speed is essential. Pneumatic nailers using 2 inch coil nails allow workers to finish projects 40–60% faster than using traditional hammering.

🎪 E. Furniture, DIY & Craft Production

Even small-scale workshops benefit from these nails because:

They produce cleaner surfaces

They reduce wood splitting

They provide consistent penetration

Crafters making wooden displays, frames, or light furniture often prefer smooth shank 2 inch nails for aesthetic reasons.

Technical Manufacturing Process — How Premium 2 inch Coil Nails Are Made

To meet international standards, every 2 inch Coil Nail must undergo a precise multi-step manufacturing process. The difference between cheap nails and premium-grade nails lies in the uniformity of the wire, the tensile strength calibration, the shank design, and the final coating.

Below is a breakdown of the full production workflow:

🔩 Step 1 — Raw Steel Wire Drawing

The steel wire (usually Q195 or Q235 carbon steel) is drawn through several dies to reduce diameter to the required gauge:

13–14 gauge for standard nails

15 gauge for light-duty applications

Uniform wire diameter ensures that nails feed smoothly inside pneumatic tools.

⚙️ Step 2 — Nail Forming & Shaping

Each nail is automatically cut and shaped:

The head is flattened or checkered

The shank is rolled (smooth/screw/ring)

The point is beveled for reduced penetration force

Precision forming is crucial for preventing misfires.

🔁 Step 3 — Coil Collation

Nails are arranged at a fixed angle (usually 15 degrees) and then welded together using high-speed copper welding.

A standard coil contains:

200–350 nails depending on gauge

Coils per box: 15–20

Boxes per set: enough to reach 9000pcs

The coil shape allows smooth feeding into CN55, CN57, CN70 nailers.

🛡️ Step 4 — Protective Coating

Coating options include:

Electro-galvanized (EG) for general use

Hot-dip galvanized (HDG) for outdoor, coastal areas

Vinyl coating to reduce friction

Stainless-style coating for corrosion resistance

The coating ensures the nails can survive moisture, rainwater, and chemicals common in industrial environments.

🧪 Step 5 — Heat Treatment for Tensile Strength

Premium coil nails undergo heat treatment to increase:

Shear strength

Bend resistance

Impact durability

A well-treated nail can bend to 25–28 degrees before cracking.

📦 Step 6 — Packaging: 9000pcs Bulk Set

Finally, the coils are packed into moisture-proof boxes:

Strong enough for export

Easy to stack in warehouses

Labeled for shank type, head type, gauge, and coating

Quality packaging prevents rusting during sea freight and long-term storage.

Coil Nails 2″ x 0.099 (2.5x50mm)

Performance Comparison — Why 2 inch Coil Nails Outperform Loose Nails & Stick Nails

To understand why global contractors are shifting to 2 inch Coil Nails, we need to examine the performance differences compared to traditional loose nails and stick nails. Although many contractors assume all nails behave similarly, small changes in shank geometry, head shape, diameter, and feeding style can dramatically affect the strength, durability, and safety of the final structure.

Below is a detailed comparison:

🔥 A. Speed of Installation

Loose Nails

1 worker can hammer around 400–600 nails per hour.

High fatigue → slower progress after 2–3 hours.

Frequent bending and misalignment.

Loose nails

Stick Nails

1,000–1,400 nails per hour using rapid-fire tools.

Must frequently reload strips → downtime.

2 inch Coil Nails

2,500–3,000 nails per hour.

Coils contain up to 350 nails → almost continuous firing.

Zero bending, zero slipping.

Speed Winner: 2 inch Coil Nails — 2–5× faster.

🛡️ B. Holding Power & Withdrawal Resistance

Smooth shank: strong general hold, best for speed.

Screw shank: best resistance to vibration, tension, impact.

Ring shank: highest withdrawal resistance—perfect for pallets, roofing, and structural wood.

Tests show:

| Nail Type | Avg Withdrawal Force |

|---|---|

| Loose Nails (smooth) | 650–800 N |

| Stick Nails (mixed) | 900–1,100 N |

| 2 inch Coil Nails (ring) | 1,300–1,600 N |

Holding Power Winner: Ring Shank 2 inch Coil Nails

🌧️ C. Corrosion Resistance

Most coil nails are available in EG, HDG, or stainless variants.

Cheap loose nails often rust in 1–2 months outdoors.

Tests after 720–1,000 hours salt spray exposure show:

Loose nails → heavy red rust

Stick nails → moderate rust

HDG 2 inch Coil Nails → minimal or no rust

This makes them ideal for:

Coastal regions

Construction near rivers, lakes

Outdoor frames and fences

Marine docks

Waterproof packaging crates

🧰 D. Tool Compatibility & Reliability

Loose nails depend entirely on the operator’s hammering consistency.

Stick nails often jam when:

Strips break

Nails misalign

Glue melts under heat

2 inch Coil Nails, however:

Feed smoothly

Are designed for high-speed pneumatic coil nailers

Maintain perfect alignment

Reduce misfires to nearly zero

Professional contractors widely report less than 1% jam rate, even in long shifts.

📌 E. Safety

Loose nails →

✔ frequent ricochet

✔ high rate of finger and hand injuries

✔ bending causes unpredictable trajectories

Stick nails →

✔ glue fragments can detach

✔ strips may break under pressure

2 inch Coil Nails →

✔ enclosed coil keeps nails contained

✔ firing angle is stable

✔ no flying debris

✔ minimal operator fatigue

2 inch Coil Nails are by far the safest option for high-volume projects.

Conclusion of Comparison

When evaluating speed, strength, consistency, rust resistance, and safety, 2 inch Coil Nails are superior on every major technical metric, confirming why they dominate professional construction, pallet manufacturing, and roofing markets worldwide.

How to Choose the Right 2 inch Coil Nails — Shank Type, Head Type, Gauge & Coating

Choosing the right nail is crucial for durability, safety, and performance. Many beginners simply buy “2 inch nails,” but professionals know that small variations affect the entire project.

Below is the complete buyer’s guide.

A. Choose by Shank Type

1. Smooth Shank

Best for fast production

Easiest penetration

Ideal for framing, general carpentry, furniture

2. Screw Shank

Twisted spiral design

Medium-to-high holding power

Great for hardwood, pallets, vibration-heavy areas

3. Ring Shank

Highest withdrawal resistance

Suitable for roofing, pallet decks, crates, sheathing

Prevents nails from backing out over time

B. Choose by Head Type

Checkered Head

Textured pattern

Prevents slippage during firing

Best for roofing or angled surfaces

Flat Head

Larger contact area

Creates a flush and stable seal

Ideal for sheathing and plywood

C. Choose by Gauge (Diameter)

Common diameters for 2 inch Coil Nails:

0.083” (15 gauge) — light-duty

0.090” (14 gauge) — standard

0.099” (13 gauge) — heavy-duty

Thicker = stronger hold.

Roofing → 0.090

Palettes → 0.099

Furniture → 0.083

D. Choose by Coating

1. Electro-Galvanized (EG)

Indoor use

Light corrosion protection

2. Hot-Dip Galvanized (HDG)

Thick zinc layer

Best for outdoor & coastal regions

3. Vinyl Coated

Reduced friction

Smoother penetration

Higher holding power once glue activates

4. Stainless STYLE

Ultimate corrosion resistance

Marine, wet, or chemical environments

E. Choose by Angle & Collation

Most 2 inch coil nails are:

15-degree angle

Wire-welded collation

Compatible with:

CN55

CN57

CN70

Max, Hitachi/Metabo, Bostitch, Senco coil nailers

F. Match Nails to Wood Type

| Wood Type | Recommended Shank |

|---|---|

| Softwood plywood | Smooth |

| Hardwood | Screw |

| Wet lumber | Ring |

| Treated lumber | HDG screw/ring |

G. Environmental Considerations

If the structure will face:

Rain → choose HDG

Saltwater → choose stainless style

Heat & humidity → choose vinyl coating

High vibration → choose screw or ring

Packaging, Storage & Safety Guidelines

Even premium nails fail early if stored incorrectly. To maximize lifespan, follow these guidelines:

A. Packaging Standards

Most 2 inch Coil Nails 9000pcs sets include:

Waterproof carton

Inner plastic liner

Silica gel packs

Clear labeling for shank/head/gauge/coating

This ensures zero rust during shipping and container storage.

B. Storage Conditions

Keep humidity below 60%

Avoid direct sunlight

Stack on pallets, not on concrete floors

Keep away from acid or chemical areas

Use within 24 months for best performance

If rust appears lightly, it can be removed by:

Steel brush

Light oil wipe

High-pressure air cleaning

C. Nail Gun Safety

Wear eye protection

Maintain 90–120 PSI

Lubricate tool every 5,000 shots

Check coil direction

Replace worn drivers immediately

Why Global Buyers Trust Vietnamese Manufacturers for 2 inch Coil Nails

Vietnam has become one of the world’s major coil nail production hubs thanks to:

Advanced Japanese & Korean machinery

Skilled labor

Competitive costs

Strong QC processes

Consistent export reliability

Factories in Bình Dương, Đồng Nai, and Bắc Ninh collectively export:

20,000+ tons of coil nails annually

To USA, Canada, Mexico, Korea, Japan, EU

Vietnamese coil nails are known for:

High zinc coating quality

Smooth weld lines

Low jam rate

Perfect shank uniformity

Conclusion — Why 2 inch Coil Nails Are the Best Choice for Contractors & Industrial Buyers

Let’s recap why 2 inch Coil Nails 9000pcs Screw/Smooth/Ring Shank Set is the best choice:

✔ Faster installation — 2–5× speed increase

✔ Stronger holding power — up to 1,600 N

✔ Better durability — HDG & stainless coatings

✔ Safer — no ricochet, no bending

✔ More consistent — perfect for pneumatic guns

✔ Versatile — roofing, pallets, framing, furniture

✔ Cost-effective — fewer reloads, less breakage

For professional builders, pallet factories, and industrial users, 2 inch Coil Nails are not just a convenient fastener—they are a high-performance solution that enhances productivity, safety, and structural integrity for every project.

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production

Thank you for taking the time to read this article. We hope the information proves helpful to you.