Steel nails are indispensable in the construction industry, serving as fundamental fasteners that ensure the structural integrity and safety of buildings. From residential homes to large-scale industrial projects, the proper selection and application of steel nails are crucial for achieving durable and reliable constructions. This comprehensive guide delves into the essential aspects of using steel nails effectively, covering selection criteria, quality assessment, application techniques, common pitfalls, storage practices, and technological advancements.

MỤC LỤC BÀI VIẾT

Choose the right steel nail

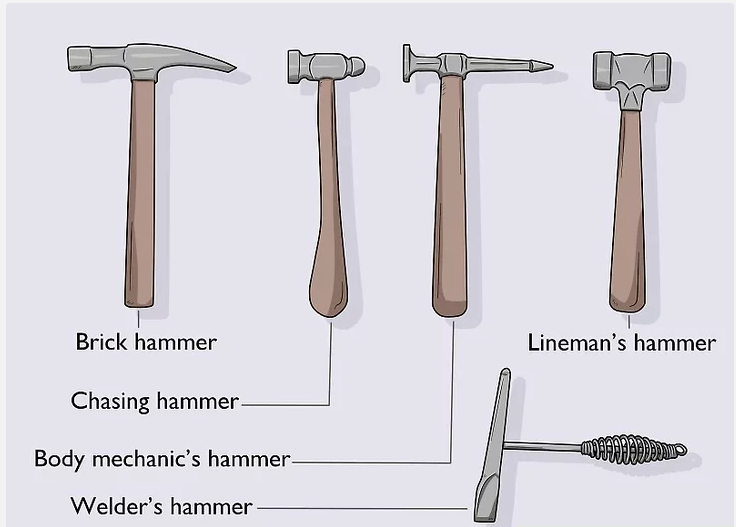

Choosing the right type of steel nail is paramount to the success of any construction project. The selection process should consider several factors:

Material and Coating: Steel nails come in various materials and coatings, each suited for specific applications.

Galvanized Steel Nails: Coated with a layer of zinc, these nails offer enhanced corrosion resistance, making them ideal for outdoor and high-humidity environments.

Stainless Steel Nails: Known for their superior strength and resistance to rust, stainless steel nails are suitable for harsh chemical environments and marine applications.

Electro-Galvanized Nails: These nails undergo an electrolytic process to apply a thin zinc coating, providing moderate corrosion resistance for indoor applications.

United Nail Products specializes in providing OEM and ODM services, so we can meet all customers' requirements on size and specifications.

Size and Length: The size of the nail should be appropriate for the material being fastened. A general guideline is that the nail length should be at least three times the thickness of the material. For instance, a 3-inch nail is suitable for fastening a 1-inch thick board.

Head Type: The nail head should be chosen based on the finish required. Flat heads are common for structural applications, while countersunk heads are preferred for finishing work to allow the nail to sit flush with the surface.

Shank Type: Nails with ringed or spiral shanks provide increased holding power, making them suitable for applications subjected to vibrations.

Assessing Nails Quality

The quality of steel nails directly impacts the safety and longevity of a structure. To ensure high-quality nails:

Material Composition: Opt for nails made from high-carbon steel or stainless steel, as these materials offer superior strength and resistance to bending or breaking.

Surface Finish: Examine the nails for any signs of rust, pitting, or surface defects. High-quality nails should have a smooth, uniform surface free from imperfections.

Certification and Standards: Ensure that the nails comply with relevant industry standards and certifications, such as ASTM or ISO, to guarantee their performance and reliability.

United Nail Products has achieved the ISO 9001:2015 Certification, demonstrating our commitment to meeting international quality standards.

Proper Nailing Techniques

Employing correct nailing techniques enhances the effectiveness of steel nails and prevents damage to materials:

Pre-Drilling: For hardwoods or materials prone to splitting, pre-drill pilot holes slightly smaller than the nail diameter to facilitate easier insertion and reduce the risk of splitting.

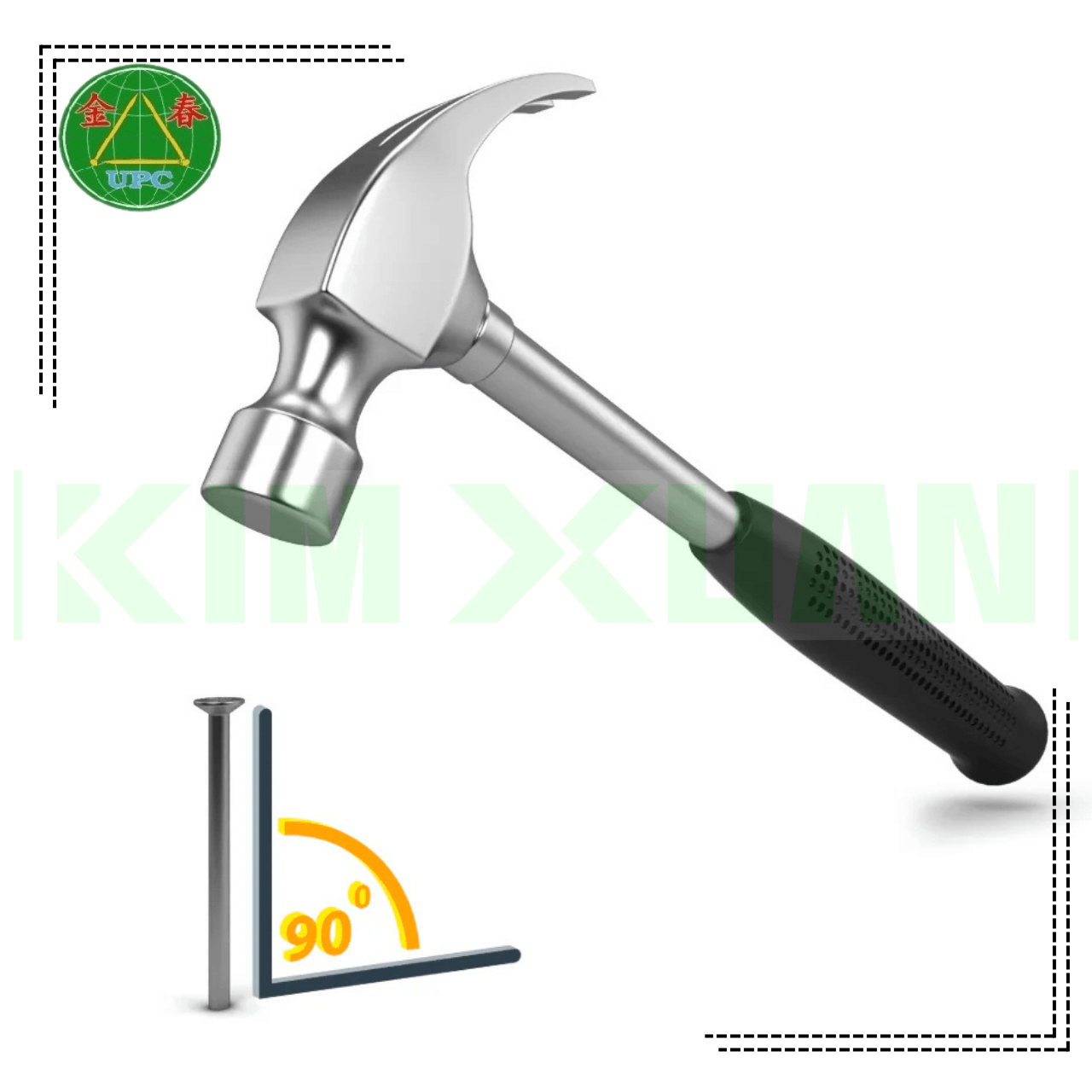

Nail Placement: Position nails at a 90-degree angle to the surface to ensure maximum holding strength. For edge placements, maintain a distance of at least 1.5 inches from the edge to prevent material splitting.

Hammering Technique: Use a hammer with a comfortable grip and appropriate weight for the task. Strike the nail squarely to drive it in straight and avoid bending.

Nail Guns: When using pneumatic or electric nail guns, ensure they are compatible with the selected nails and are set to the correct depth to prevent overdriving or underdriving the nails.

Common Mistakes to Avoid

To achieve optimal results and maintain structural integrity, avoid the following common errors:

Overdriving Nails: Driving nails too deep can weaken the material and reduce holding power. Ensure nails are driven just below the surface.

Incorrect Nail Length: Using nails that are too short may not provide adequate holding strength, while nails that are too long can cause material damage.

Improper Nail Spacing: Inconsistent spacing can lead to uneven load distribution and potential structural weaknesses.

Using Corroded Nails: Corroded nails can compromise the integrity of the structure and should be discarded.

Storing and Handling Steel Nails

Proper storage and handling of steel nails are essential to maintain their quality and prevent damage:

Storage Conditions: Store nails in a dry, cool environment to prevent rust and corrosion. Avoid areas with high humidity or exposure to chemicals.

![]()

Organization: Keep nails organized by size and type in labeled containers to facilitate easy access and prevent mix-ups.

Handling Practices: Handle nails carefully to avoid bending or damaging them. When transporting, use appropriate containers to prevent movement and potential damage.

Integrating Nails with Other Fastening Methods

In some applications, combining steel nails with other fastening methods can enhance performance:

Screws: Use screws in conjunction with nails for applications requiring higher holding power or where removal and repositioning may be necessary.

Adhesives: In certain scenarios, applying construction adhesives alongside nails can provide additional bonding strength, particularly in non-structural applications.

Anchors: For heavy-duty applications, consider using anchors in conjunction with nails to distribute loads more evenly and enhance stability.

Technological Advancements in Nail Manufacturing

Advancements in manufacturing technology have significantly improved the performance, consistency, and durability of steel nails used in construction. Some notable innovations include:

Automated Production Lines: Modern nail factories employ automated systems for wire feeding, cutting, heading, and point shaping. This ensures each nail meets exacting size and quality specifications, reducing variability between batches.

Advanced Surface Treatments: New galvanization and coating technologies—such as hot-dip galvanizing, electroplating, epoxy coatings, and ceramic finishes—offer superior rust resistance and bonding characteristics, especially critical in high-humidity and coastal environments.

Heat Treatment Processes: Heat-treated nails undergo controlled heating and cooling cycles to improve their hardness and flexibility, ensuring better performance under load and minimizing risks of snapping or bending.

Quality Control & Inspection Systems: High-speed imaging and AI-powered defect detection systems allow manufacturers to remove substandard products before they reach the end user.

Eco-Friendly Production: Environmentally conscious producers are now minimizing waste and reducing harmful chemical usage during production, aligning with green building certifications such as LEED or WELL standards.

Evaluating On-Site Nail Performance

After nails have been applied in a construction project, it’s essential to evaluate their performance both during and after installation:

Structural Integrity Checks: Regularly assess whether the fastened materials remain securely attached over time. Pay attention to any signs of nail loosening, surface cracking, or movement under load.

Load Testing: For critical applications (e.g., load-bearing walls, framing), perform field tests to verify that nailed joints can withstand expected loads and stresses.

Corrosion Monitoring: In humid or coastal environments, inspect exposed nails for signs of early corrosion. Use corrosion-resistant nails for long-term protection in such cases.

Thermal Movement Observations: In regions with large temperature variations, materials may expand or contract. Ensure nails allow for some flexibility or are combined with other fastening solutions to avoid splitting or failure.

Jobsite Management for Efficient Nail Usage

Efficient usage of nails also depends on good construction site management practices:

Material Forecasting and Inventory Management: Ensure that the correct types and quantities of nails are ordered based on project requirements. Maintain organized records of usage to avoid shortages or overstocking.

Tool Maintenance: Regularly check that hammers, nail guns, and other fastening tools are in proper working condition. A poorly calibrated nail gun can lead to underdriven or misfired nails, compromising quality.

Training and Supervision: Make sure workers are trained in proper nailing techniques, safety precautions, and efficient usage practices. Assign experienced supervisors to oversee fastening stages of construction.

Waste Reduction Strategies: Encourage efficient use of nails by discouraging unnecessary or excessive nailing. Reuse unused or unbent nails whenever possible, and dispose of damaged nails responsibly.

Knowledge Sharing and Continuous Improvement

As construction techniques and materials evolve, it’s essential for professionals to continuously update their knowledge and practices:

On-Site Debriefings: At the end of major tasks, hold brief team discussions to reflect on what worked well and what could be improved in nail usage and related procedures.

Documentation of Best Practices: Maintain a written record (or digital log) of nail types, techniques, and supplier feedback that yielded the best results. This helps with standardizing future projects.

Workshops and Supplier Consultations: Collaborate with nail manufacturers or construction consultants to conduct workshops or training sessions for your teams.

Technology Trials: Be open to testing new nail products or technologies in pilot areas before full-scale adoption. Record the performance and share findings with the team.

Conclusion

Steel nails are deceptively simple yet indispensable components in any construction project. Their correct selection, application, and maintenance directly affect the integrity, longevity, and overall success of a build. By following the practical tips and industry insights outlined above—ranging from choosing the right type of nail and applying proper techniques to embracing technological innovations, you can significantly enhance both the efficiency and safety of your construction process.

Whether you’re a site engineer, contractor, architect, or builder, remember that attention to detail in something as small as a nail can make a big difference in the final outcome. Proper nail usage reduces rework, prevents structural failures, improves appearance, and helps meet both safety standards and client expectations.

If you have further questions, need technical guidance, or want to explore high-quality steel nail solutions, don’t hesitate to contact United Nail Products Co., Ltd. Our team is here to support your construction success with reliable products and professional advice.

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production

Thank you for taking the time to read this article. We hope the information proves helpful to you.