In Vietnam’s vibrant countryside and bustling construction sites, where rice fields meet skyscrapers, the need for reliable, versatile materials is undeniable. From securing rebar in towering buildings to fencing lush farmlands, Annealed Binding Wire from United Nail Products Co. Ltd, crafted from high-quality carbon steel sourced from trusted Vietnamese partners, is transforming industries. This soft, durable wire offers unmatched flexibility and strength, making it a cornerstone for construction and agriculture worldwide. By reducing waste and enhancing efficiency, Annealed Binding Wire aligns with the global push for sustainability, empowering businesses in Japan, Canada, Thailand, and beyond. This article explores how this humble wire is revolutionizing trade and building a greener future.

MỤC LỤC BÀI VIẾT

Why Annealed Binding Wire Is Essential for Construction and Agriculture

Global construction and agriculture industries drive economic growth, but their environmental impact is a pressing challenge. Construction consumes billions of tons of steel annually, with rebar binding alone accounting for significant material use.

In agriculture, millions of hectares rely on fencing and trellising to protect crops and livestock,

…yet inefficient materials lead to frequent replacements and waste.

Industry data estimates that over 30% of fencing materials fail within five years due to corrosion or poor flexibility, while construction binding errors contribute to 25% of structural delays. These inefficiencies inflate costs and harm the environment.

United Nail’s Annealed Binding Wire addresses these issues with precision and sustainability. Its soft, pliable nature ensures easy handling, while its strength secures critical applications. Compliant with international standards like ASTM and ISO, this wire meets the demands of markets like Japan, Canada, Thailand, the United States, Italy, and Australia. By choosing Annealed Binding Wire, businesses reduce waste, enhance durability, and invest in eco-friendly practices that strengthen global trade.

1mm Steel Wire

The Strength of Annealed Binding Wire: Key Features for Diverse Applications

Our Annealed Binding Wire is engineered for versatility and performance, making it ideal for construction and agriculture. Here’s why it excels:

- Superior Flexibility: Heat-treated for optimal softness, Annealed Binding Wire bends effortlessly, enabling quick binding of rebar or intricate fencing patterns, reducing labor time by up to 20%.

- High Tensile Strength: With a tensile strength of 350–450 MPa, this wire withstands heavy loads in construction and resists snapping in agricultural applications.

- Corrosion Resistance: Available with galvanized or PVC coatings, our wire resists rust, ensuring longevity in humid climates like Thailand or coastal Australia.

Black Annealed Tie Wire – Small Coils 12G ( 2.68mm )

- Customizable Specifications: Offered in diameters from 1 mm to 3.7 mm and various spool sizes, Annealed Binding Wire suits tasks from delicate crop trellising to robust rebar binding.

- Eco-Friendly Production: Manufactured using energy-efficient processes, our wire minimizes environmental impact, aligning with sustainable practices in markets like USA and Canada.

These features make Annealed Binding Wire a vital tool for businesses seeking efficiency, durability, and sustainability in global markets.

A Story of Resilience: Ha’s Journey with Annealed Binding Wire

Hà, a rice farmer in Vietnam’s Mekong Delta, faced a recurring challenge: wild animals damaging her crops. Her traditional bamboo fences broke easily, and low-quality wire rusted within months, costing her 25% of her yield annually. With a goal to supply rice to a Thai exporter by 2025, Hà needed a durable, cost-effective solution to protect her fields. The environmental toll of frequent replacements also clashed with her commitment to sustainable farming. She sought a way to secure her livelihood while meeting export standards.

When Hà adopted United Nail’s Annealed Binding Wire, the transformation was profound. Its flexibility allowed her to craft sturdy fences quickly, while its galvanized coating withstood the Delta’s humidity. She reduced fence replacements by 80%, saving costs and boosting her yield by 20%. The wire’s strength also supported trellises for climbing vegetables, diversifying her crops. Hà’s farm earned a sustainability certification, securing the Thai contract and attracting interest from Canadian importers. Her story inspires farmers and contractors, showing how Annealed Binding Wire can drive success and sustainability.

Best Practices for Maximizing Annealed Binding Wire in Applications

To fully leverage Annealed Binding Wire, businesses can follow these best practices:

- Choose the Right Specifications: Select wire diameter (e.g., 1.2 mm for fencing, 1.6 mm for rebar) based on application. Galvanized wire suits humid environments, while PVC-coated wire enhances grip for trellising.

- Invest in Efficient Tools: Use wire cutters and tying tools designed for Annealed Binding Wire to ensure clean cuts and secure knots, reducing material waste by up to 15%.

- Train for Precision: Educate workers on binding techniques, such as double-loop ties for rebar or tensioned knots for fencing, to maximize strength and minimize errors.

- Prioritize Sustainable Sourcing: Pair Annealed Binding Wire with eco-friendly materials like recycled steel or FSC-certified wood for trellises, appealing to markets like Japan and Europe.

- Implement Quality Control: Regularly inspect bindings and fences for tension and corrosion, using data to optimize wire usage and extend lifespan.

These steps ensure Annealed Binding Wire delivers maximum efficiency and sustainability across construction and agriculture.

The Global Impact of Annealed Binding Wire in Trade and Sustainability

The global push for sustainable practices is transforming industries, and Annealed Binding Wire is at the forefront. By reducing material waste and energy use, our wire helps businesses lower their carbon footprint, aligning with the United Nations’ Sustainable Development Goals.

In Japan, where strict standards govern construction, Annealed Binding Wire ensures secure rebar binding for earthquake-resistant buildings.

In Canada, farmers use it for durable livestock fencing, reducing replacements

In Thailand, agricultural exporters rely on our wire for crop trellises, while in Italy and Australia, contractors leverage it for eco-friendly projects. Vietnam’s reputation as a sustainable manufacturing hub grows with our wire.

United Nail’s sustainability commitment extends beyond products. Our Vietnamese facilities employ energy-efficient processes, and we partner with suppliers prioritizing sustainable sourcing. We invest in research to develop advanced coatings, ensuring Annealed Binding Wire remains a leader in green innovation. By choosing our wire, businesses join a global movement to protect the planet.

Case Studies: Real-World Success with Annealed Binding Wire

The versatility of Annealed Binding Wire shines across borders. A Vietnamese construction firm building a bridge in Hanoi used our wire for rebar binding, reducing binding errors by 22% and speeding up project timelines. In Italy, a vineyard owner adopted Annealed Binding Wire for grape trellises, cutting maintenance costs by 25% and earning eco-certifications. In Thailand, a shrimp farm used our wire for fencing, increasing durability by 30% and securing contracts with Australian importers. These cases highlight how Annealed Binding Wire drives cost savings, efficiency, and sustainability.

In Vietnam, small businesses also benefit. A family-owned farm in Dong Nai switched to Annealed Binding Wire for fencing and trellising, boosting crop protection by 35% and securing deals with Canadian clients. These success stories demonstrate how Annealed Binding Wire empowers businesses of all sizes to thrive in global markets while prioritizing sustainability.

Expanding Applications: Annealed Binding Wire Beyond the Basics

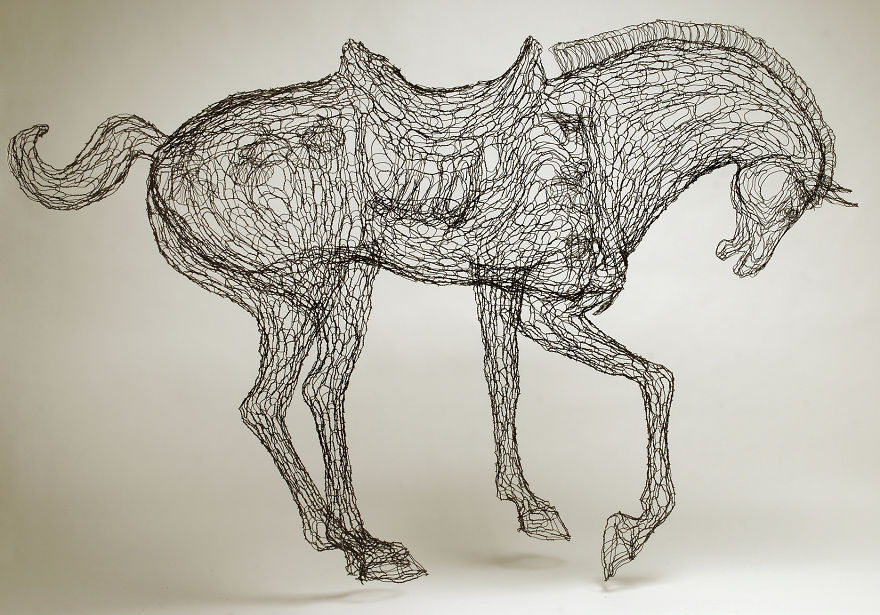

Beyond construction and agriculture, Annealed Binding Wire finds innovative uses. In logistics, it secures wooden crates for electronics exports, ensuring stability during long sea voyages to the U.S. In artisanal crafts, Vietnamese workshops use it for decorative wire sculptures, blending tradition with modern trade. In renewable energy projects, contractors in Australia use our wire to stabilize solar panel frames, supporting clean energy goals. These diverse applications showcase the wire’s adaptability, making it a valuable asset for industries worldwide.

Tang Horse artwork from Bored Panda

The wire’s eco-friendly profile further enhances its appeal. Its recyclability reduces landfill waste, and its energy-efficient production aligns with circular economy principles. In markets like Japan and Canada, where sustainability is a priority, Annealed Binding Wire helps businesses meet regulatory requirements while maintaining cost-effectiveness. As industries evolve, our wire remains a trusted solution for emerging challenges.

Partner with United Nail for Annealed Binding Wire and a Sustainable Future

At United Nail Products Co. Ltd, we believe small materials drive big change. Our Annealed Binding Wire, crafted from high-quality carbon steel sourced from trusted Vietnamese partners, empowers farmers, contractors, and exporters to build stronger, greener futures. From Hà’s farm in the Mekong Delta to construction sites in Japan and vineyards in Italy, our wire is shaping sustainable industries. Whether you’re fencing fields in Thailand or binding rebar in Canada, United Nail is your partner in precision and sustainability.

Contact us today to request a quote, order samples, or explore how Annealed Binding Wire can transform your operations. Together, let’s secure a future where every project carries the promise of a healthier planet.

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production

Thank you for taking the time to read this article. We hope the information proves helpful to you.