MỤC LỤC BÀI VIẾT

Choose Galvanized Wire and Steel Nails Based on Project Characteristics and Usage Needs

When embarking on any construction or renovation project, selecting the right materials is crucial for both durability and safety. Among the top considerations are galvanized wire and steel nails, two essential materials used across various industries. However, choosing the correct type of wire and steel nails for your specific project can greatly influence the outcome and longevity of your construction work. Here’s a guide to understanding these materials, their features, and how to make an informed decision.

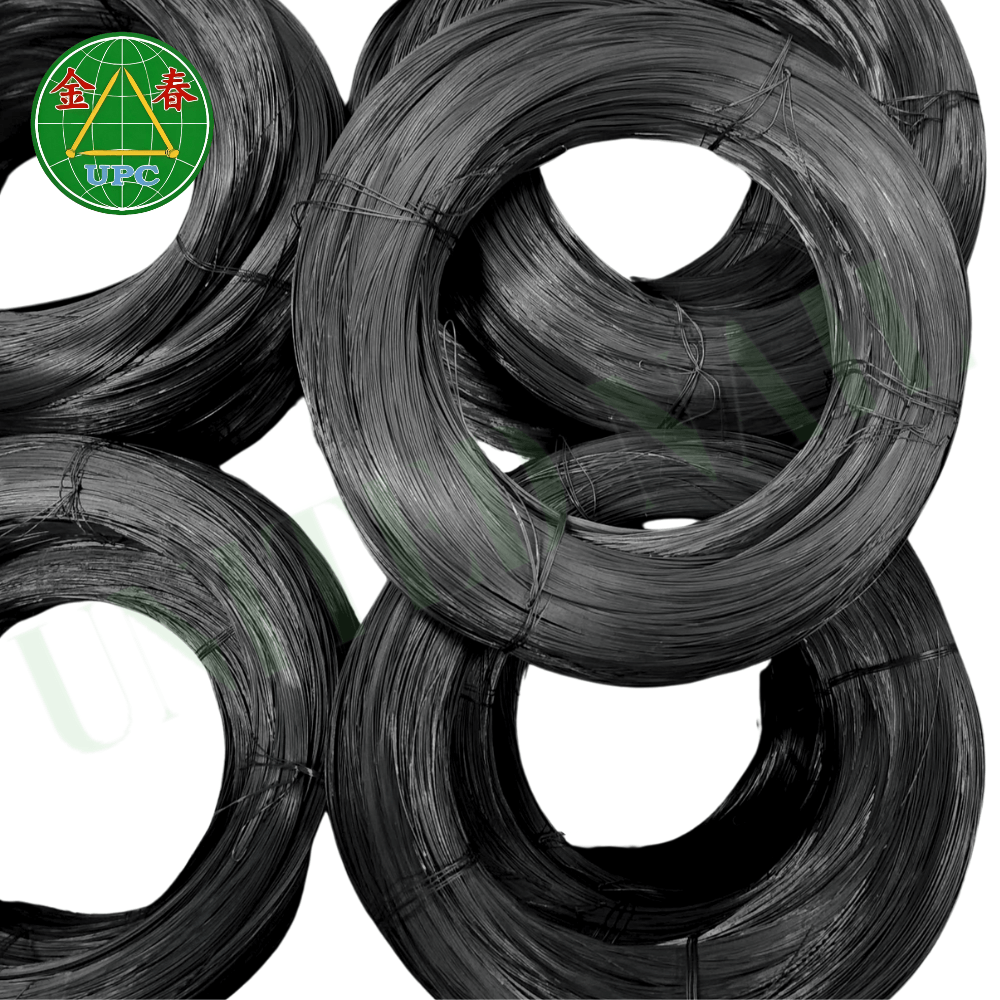

Understanding Tie Wire: Durability and Versatility

In agricultural projects, for example, tie wire is often used for fencing, while in industrial settings, it can be applied in cable reinforcements. Its flexibility allows it to be adapted to various shapes and structures, making it a versatile option across many fields.

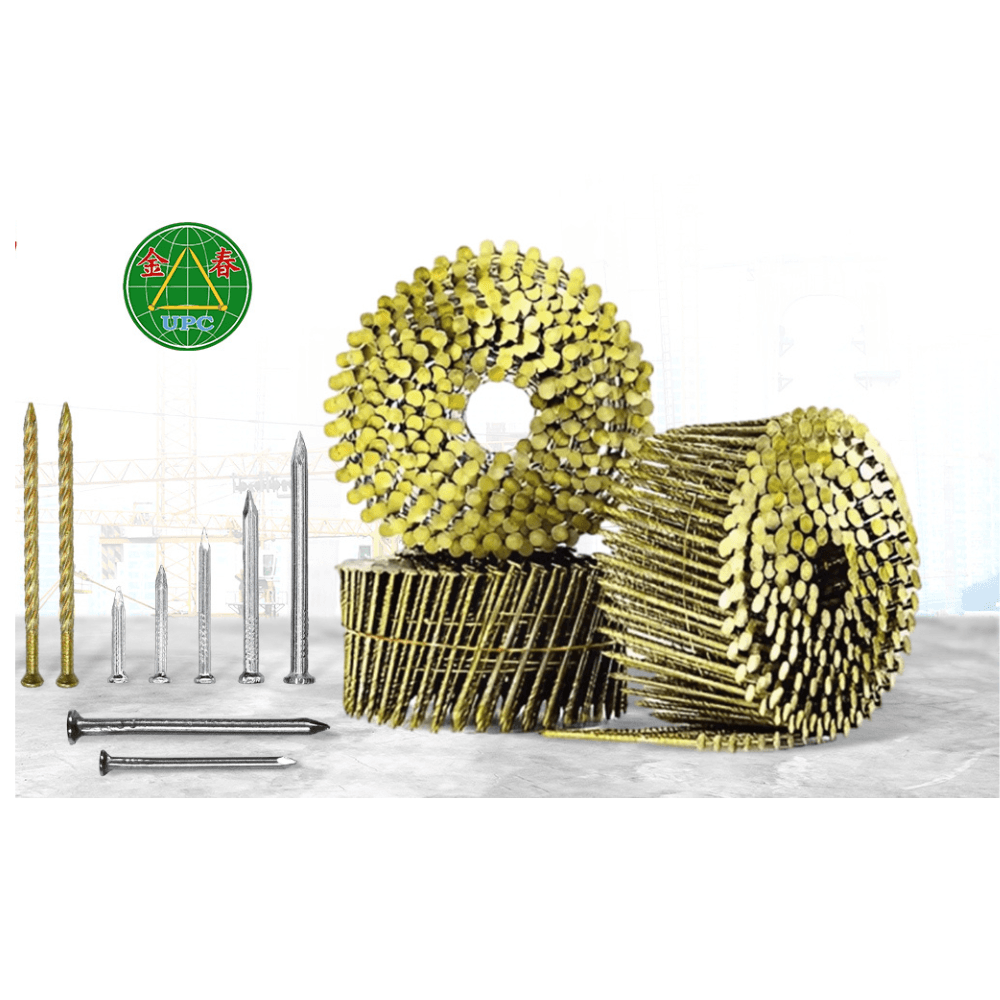

Types of Steel Nails: Tailoring to Your Construction Needs

Steel nails are widely used in both large-scale construction and DIY projects. The different types of nails available – such as framing nails, finishing nails, and roofing nails – offer specific benefits depending on the nature of your project. Selecting the correct steel nail involves evaluating the type of material you’re working with and the amount of load or pressure it will need to endure.

For instance, roofing nails need to have larger heads to secure shingles properly, while framing nails, which bear a lot of structural weight, should be longer and thicker to provide solid support. By choosing the right type of nail, you can ensure the strength and safety of your structure.

Why Tie Wire Is Ideal for Outdoor Projects

When dealing with outdoor installations, such as garden trellises, wire fencing, or protective cages, tie wire proves to be an excellent choice. The zinc coating not only extends the lifespan of the wire but also minimizes maintenance efforts. In environments where moisture is present, like in gardens or along coastal areas, the anti-corrosive properties of tie wire become invaluable.

For construction involving long-term exposure to the elements, always opt for a higher-grade galvanization to ensure the best protection against rust and wear.

Choosing Steel Nails for Specific Applications

Different types of projects require varying strengths and styles of nails. For heavy-duty construction, such as building wooden frameworks or installing hardwood floors, steel nails provide the necessary durability. In applications like drywall installation, finishing nails made from steel offer a sleek, unobtrusive hold without damaging the surface.

The selection of steel nails must consider factors like the required load-bearing capacity and the material you’re fastening. A common mistake is underestimating the importance of using appropriate nail lengths and types for different jobs, which can lead to structural weaknesses.

The Environmental Impact: Why Tie Wire and Steel Nails Are Sustainable

Both tie wire and steel nails are recyclable, making them more environmentally friendly than other materials. In an era where sustainability is key, choosing materials that can be reused or recycled aligns with green building practices. Steel, in particular, retains its properties even after recycling, which ensures that reusing it does not compromise the quality or strength of future projects.

The Cost Factor: Balancing Budget with Quality

While both tie wire and steel nails are affordable options for most projects, it’s important to balance cost with quality. Cheaper alternatives may seem tempting but can result in poor durability and additional costs for repairs or replacements in the long run. It’s always better to invest in high-quality materials that provide longevity and safety, especially for projects requiring long-term structural integrity.

Conclusion: How to Make the Right Choice

Selecting the right tie wire and steel nails depends on the specific demands of your project. Understanding the characteristics of these materials and matching them with your construction requirements is key to achieving a durable and reliable outcome. Whether you’re working on a large industrial project or a small-scale home renovation, the choices you make tie wire and steel nails will significantly impact the longevity and safety of your work.

By taking the time to assess the conditions in which these materials will be used – from exposure to the elements to the weight-bearing needs – you can make informed decisions that lead to superior results.

UNITED NAIL PRODUCTS CO., LTD

Address: 16A8, Tra Noc Industrial Zone 1, Tra Noc Ward, Binh Thuy District, Can Tho City, Viet Nam

Phone: (+84) 986 831838; (+84) 292 242165

• Facebook: Đinh Kim Xuân

Thank you for reading this article, hope the information is useful to you.