When it comes to construction, woodwork, or even home improvement, coil nails (also known as coil nails) are essential for anyone using nail guns. They offer convenience, efficiency, and speed, especially when dealing with large-scale projects. However, using coil nails effectively requires understanding their different types, the tools needed, and the best practices to ensure a successful project. Below are five crucial tips to keep in mind when using coil nails, helping you achieve optimal results while maintaining safety and efficiency.

MỤC LỤC BÀI VIẾT

Understanding Different Types of Coil Nails

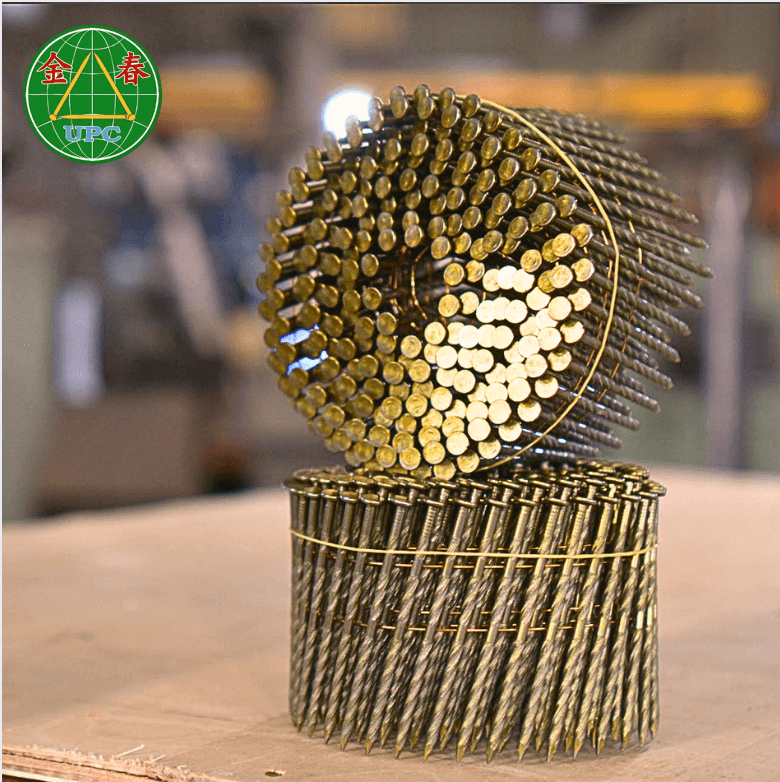

There is a variety of coil nails available, each designed for specific tasks and materials. Using the right type of roll nail for your project is key to ensuring durability and effectiveness. Some of the most common types include:

- Smooth coil nails: These nails are the most basic type, designed for general-purpose tasks. They are smooth and slide easily into materials, but they don’t offer as much holding power as other types.

- Ring coil nails: These nails have small rings along the shank that provide extra grip, making them ideal for applications where holding power is critical, such as decking or siding.

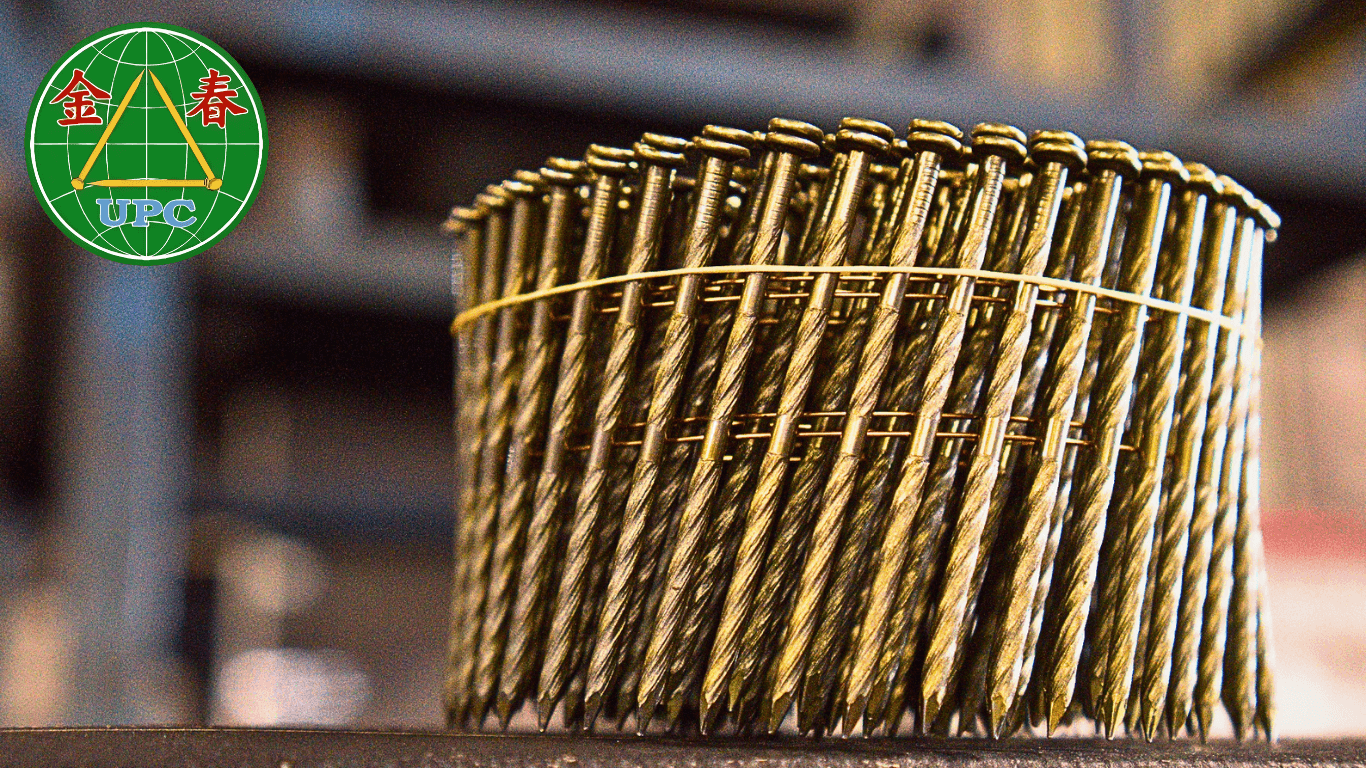

- Screw coil nails: These nails twist as they are driven into materials, offering maximum holding power and preventing materials from loosening over time.

Using the correct type of coil nail for your project will save you time, reduce material waste, and ensure a longer-lasting construction.

Tip 1: Choose the Right Nail Length and Diameter

One of the most important considerations when using coil nails is selecting the appropriate nail length and diameter. The length of the nail needs to be proportional to the thickness of the materials you’re fastening, while the diameter determines the holding power of the nail.

- For thin materials such as plywood or softwood, shorter and thinner coil nails will suffice.

- For thicker or denser materials like hardwood or treated lumber, opt for longer and thicker nails.

Using nails that are too short can lead to structural instability, while nails that are too long can cause splitting or damage to the material. In many cases, the general rule of thumb is to use a nail that is three times longer than the thickness of the material being fastened to ensure a strong and secure hold.

Tip 2: Use the Correct Nail Tool /Nail Guns

To fully leverage the benefits of coil nails, you need to use the correct type of nail tool. Coil nailers are designed specifically to handle coil nails, feeding them into the gun’s chamber and driving them with precision. Here are some important factors to consider when choosing a nail gun for your coil nails:

- Coil Nail Tool Size: Ensure the nail tool you choose is compatible with the size of the coil nails you are using. This includes both the nail diameter and length, as different nail tool are designed to handle different sizes of nails.

- Operating Pressure: Pneumatic nail tools are the most common type of nailer used with coil nails, and they require an air compressor. Make sure that the air pressure provided by your compressor matches the specifications required for the nails and material you’re working with.

- Depth Adjustment: A good coil nailer will allow you to adjust the depth at which the nails are driven. This is crucial for ensuring that nails are not overdriven or underdriven, both of which can cause problems such as weak fastening or material damage.

Investing in a high-quality nail gun that is designed for use with coil nails will make your work faster, more efficient, and more precise, helping you achieve professional results.

Tip 3: Store Coil Nails Properly to Avoid Corrosion

Coil nails are often used in exterior applications such as fencing, siding, and roofing, where exposure to the elements is common. One major concern with coil nails, particularly those made of steel, is the potential for rust and corrosion. Proper storage is essential to maintaining the quality of your nails and ensuring they remain effective over time.

Here are a few tips to store your coil nails properly:

- Keep Nails Dry: Moisture is the number one enemy of coil nails. Store them in a dry place to prevent rust. If possible, keep them in their original packaging until you’re ready to use them.

- Seal Packaging: Once the original packaging is opened, it’s important to seal the nails in an airtight container. This will help prevent exposure to humidity and prolong the life of the nails.

- Use galvanized or stainless steel nails for exterior projects: For outdoor applications, consider using galvanized or stainless steel coil nails. Galvanized nails are coated with zinc, which offers protection against rust, while stainless steel nails are naturally resistant to corrosion.

Taking care of your coil nails and ensuring they are stored properly will help you avoid unnecessary issues like rust, which can weaken the nails and compromise the structural integrity of your project.

Tip 4: Match the Coil Nail Material to the Application

When working with coil nails, it’s important to choose the right material based on the environmental conditions and the materials you are fastening. Different projects require different types of nails, and using the correct material can make a significant difference in durability and performance.

- Steel Coil Nails: Steel is the most common material used for coil nails due to its strength and versatility. Steel nails are ideal for general construction tasks, but they can be prone to rust if not protected.

- Galvanized Coil Nails: For projects exposed to moisture, galvanized nails are a great choice. These nails are coated with a layer of zinc that helps prevent rust and corrosion, making them suitable for outdoor applications like decking, fencing, and roofing.

- Stainless Steel Coil Nails: Stainless steel nails offer the best corrosion resistance, making them ideal for harsh environments such as coastal areas or places with high humidity. Although they are more expensive, stainless steel nails provide long-term durability and are worth the investment for critical exterior applications.

Choosing the right material for your coil nails will not only ensure the strength of your project but will also help protect against the elements, extending the lifespan of your work.

Tip 5: Regular Maintenance of Your Nail Tool

Properly maintaining your nail gun is essential for ensuring that your coil nails are driven correctly and efficiently. A poorly maintained nail gun can lead to misfires, jams, and even damage to the materials you are working with. Regular maintenance ensures smooth operation and prolongs the life of both your nail gun and your coil nails.

Here are a few tips for maintaining your nail tool:

- Clean Regularly: After each project, clean the nail gun to remove any dust, debris, or residue that may have accumulated. This will help prevent jams and ensure smooth operation.

- Lubricate Moving Parts: Pneumatic nail guns require regular lubrication to ensure that the moving parts function properly. Lubricating the tool according to the manufacturer’s instructions will help prevent friction and wear on the internal components.

- Check Air Pressure: Ensure that your air compressor is providing the correct pressure for your nail gun. Too much or too little pressure can lead to nails being driven too deeply or not deeply enough, both of which can cause issues.

By maintaining your nail gun, you will ensure that every coil nail is driven accurately and securely, leading to better results and less downtime due to equipment failure.

The Importance of Following Safety Procedures

Safety is a critical factor when using roll nails and nail guns. Failing to follow safety guidelines can result in serious injuries. Some important safety practices to follow include:

- Always wear safety glasses to protect your eyes from flying debris or misfired nails.

- Wear hearing protection, especially when using pneumatic nail guns for extended periods.

- Keep your hands away from the nail point and only fire when the gun is in the correct position on the material.

- Never point the nail gun at yourself or others, even when it’s not in use.

By following these safety tips, you can prevent accidents and ensure a safer working environment for you and your team.

Unnited Nail – Your Trusted Supplier for Higt-Quality Roll Nails

For all your coil nail needs, United Nail is a trusted and reliable supplier. We provide high-quality coil nails that meet the demanding standards of today’s construction industry. Whether you are looking for smooth shank, ring shank, or screw shank coil nails, we offer a variety of options in galvanized, stainless steel, and plain steel finishes to suit your specific project needs.

Our coil nails are manufactured to the highest standards, ensuring strength, durability, and corrosion resistance. With a commitment to quality, United Nail is your go-to source for all types of coil nails designed for professional-grade performance in any application.

For more information on our product offerings or to place an order, contact us today and experience the difference that high-quality coil nails can make in your next project.

UNITED NAIL PRODUCTS CO., LTD

Specializing in manufacturing high quality industrial nails and tie wire

Address: 16A8, Tra Noc Industrial Zone 1, Tra Noc Ward, Binh Thuy District, Can Tho City, VietNam

Phone: (+84) 986831838

Email: sales5@unitednail.com