MỤC LỤC BÀI VIẾT

Maximizing Performance with Plastic Strip Nails in Your Nail Gun

Plastic strip nails have become increasingly popular in the construction and woodworking industries due to their versatility, efficiency, and compatibility with a wide range of nail guns. These nails are designed to be used in high-speed nail guns, making them an essential tool for both professional builders and DIY enthusiasts. In this article, we will explore how to maximize performance with plastic nails in your nail gun, covering everything from their benefits to proper usage, maintenance tips, and application areas.

Understanding

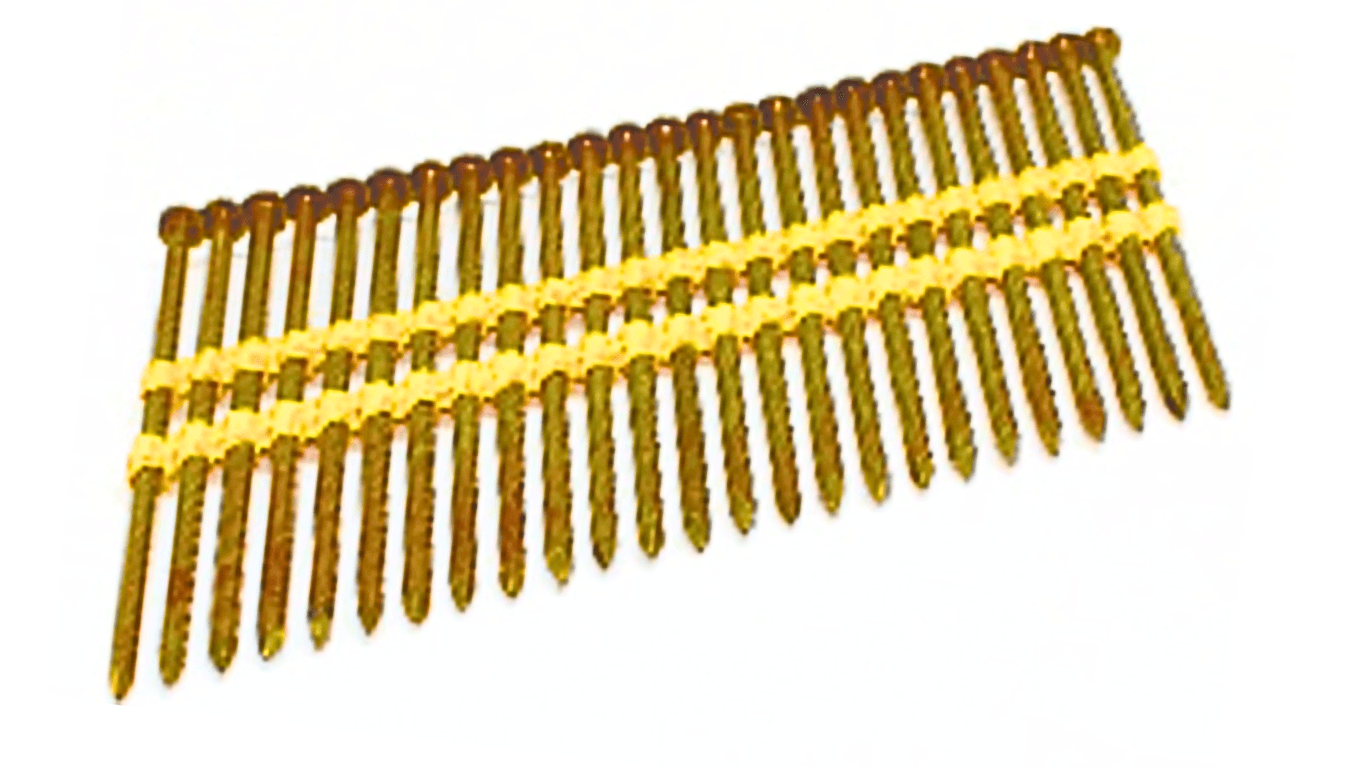

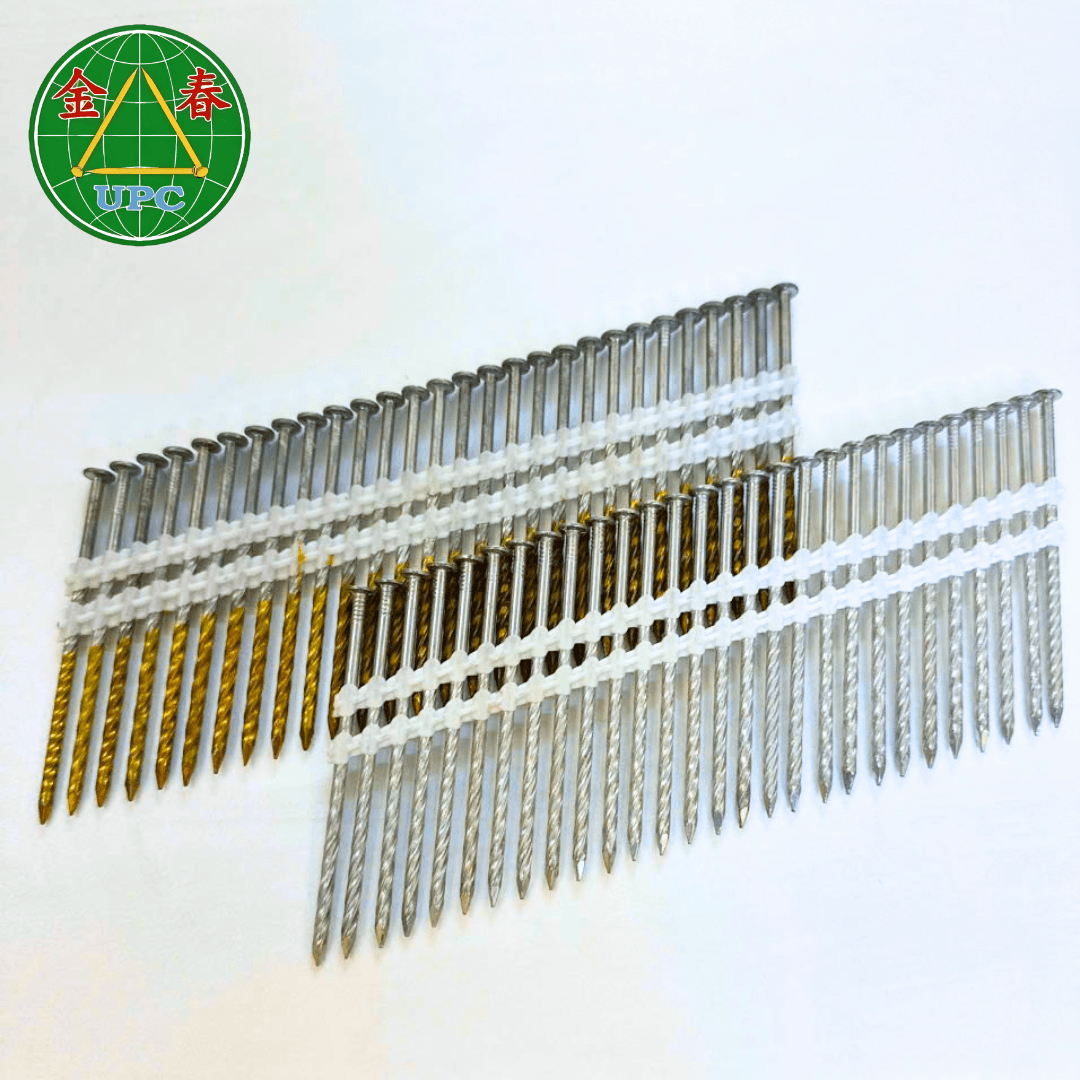

Plastic strip nails are a type of fastener that is held together by a plastic strip which acts as a collation method. This design ensures that the nails are evenly spaced, allowing for smooth feeding into nail guns during application. The plastic strip also disintegrates upon impact, reducing the chances of jamming and ensuring clean and efficient nail placement.

These nails are typically made from steel, although they can also be coated for added durability. The plastic strip offers a high degree of flexibility and strength, making them suitable for heavy-duty construction work, including framing, roofing, and flooring projects. Their ability to work seamlessly with pneumatic or cordless nail guns makes them ideal for large-scale jobs where speed and precision are crucial.

Benefits of Plastic Nails

When it comes to construction projects that require fast and secure fastening, plastic strip nails offer numerous advantages over other types of nails. Below are some key benefits:

1. Faster Application

One of the most significant advantages of using plastic strip nails is the speed of application. Since the nails are collated in strips, they are fed smoothly and rapidly into the nail gun, allowing for quick and efficient work. This is particularly beneficial in large projects, such as framing or decking, where thousands of nails may be required. The faster the application, the more time you save, making your overall workflow more efficient.

2. Reduced Jamming

Plastic strip nails are specifically designed to minimize jamming in nail guns. The plastic strip that holds the nails together is engineered to break away cleanly upon impact, preventing any fragments from getting stuck in the tool. This reduces the risk of downtime caused by jammed nails, allowing you to maintain uninterrupted workflow.

3. Lightweight and Flexible

The plastic method makes these nails lighter than other types of collated nails, such as wire-collated or paper-collated nails. This feature is particularly advantageous when working in tight spaces or when using the nail gun for extended periods. The flexibility of the plastic strip also ensures that the nails can be easily maneuvered into position, especially in applications that require precision.

4. Enhanced Durability

Many plastic strip nails are made from high-quality steel, often coated with corrosion-resistant materials such as zinc. This enhances the durability of the nails, ensuring they can withstand harsh environmental conditions, including moisture and exposure to outdoor elements. Whether you’re working on a roofing project or building a wooden deck, the added durability of these ensures long-lasting results.

5. Versatility

Come in various sizes, gauges, and finishes, making them versatile for a wide range of applications. They can be used for framing, sheathing, subflooring, decking, siding, and more. Their compatibility with different types of nail guns also adds to their versatility, making them a go-to choice for both professional contractors and hobbyists.

How to Maximize Performance with Plastic strip nails

To get the most out of your plastic nails, it’s essential to use them correctly and ensure that your nail gun is properly maintained. Below are some tips to help you maximize performance when using plastic strip nails in your nail gun:

1. Choose the Right Size and Type of Nails

Selecting the appropriate size and type of plastic strip nails is crucial for maximizing performance. Depending on the specific project you’re working on, you may need nails of different lengths and gauges. For example, shorter nails are ideal for thin materials such as plywood or paneling, while longer nails are necessary for thicker materials like framing lumber.

Additionally, consider the coating or finish of the nails. If you’re working on an outdoor project, opt for galvanized or stainless steel plastic collated nails to prevent corrosion and ensure longevity.

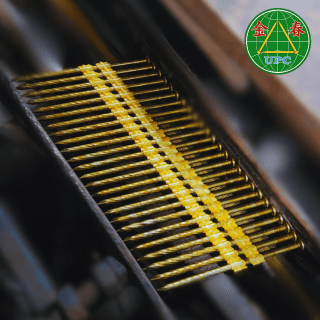

2. Use a Compatible Nail Gun

Not all nail guns are compatible with every type of plastic collated nail. Before starting your project, make sure that your nail gun is designed to work with the size and type of plastic strip nails you plan to use. Most manufacturers provide specifications on nail compatibility, so it’s essential to review these details to avoid any issues.

Using the wrong type of nail gun or incorrectly sized nails can result in poor performance, frequent jams, or even damage to your tool. Therefore, always double-check compatibility to ensure smooth and efficient operation.

3. Maintain Your Nail Gun Regularly

Regular maintenance of your nail gun is key to maximizing the performance of nails. Over time, debris, dust, and leftover fragments from nails can accumulate inside the tool, causing jams and reducing efficiency. To prevent this, clean your nail gun after each use by removing any debris and applying lubrication to moving parts.

Check for signs of wear on critical components such as the firing pin, feed mechanism, and air filter (for pneumatic nail guns). Keeping your nail gun in good condition not only ensures better performance with plastic collated nails but also extends the lifespan of your tool.

4. Adjust Air Pressure for Pneumatic Nail Guns

For those using pneumatic nail guns, adjusting the air pressure is essential for proper nail application. Different materials require varying levels of air pressure to drive the nails correctly. For instance, hardwood may require higher pressure than softwood to ensure that the nails penetrate deeply without splitting the wood.

Be mindful of the recommended pressure levels for both your nail gun and the plastic collated nails you’re using. Applying too much or too little pressure can result in overdriving or underdriving the nails, affecting the quality of your work.

Applications

Plastic strip nails are versatile and can be used in various construction and woodworking applications. Below are some common areas where these nails excel:

1. Framing

Framing is one of the most common applications for this product. Whether building a house, shed, or deck, these nails provide the strength and durability needed to create a solid framework. Their ability to be driven quickly and securely makes them ideal for large-scale framing projects where speed is essential.

2. Roofing

In roofing applications, it is commonly used to secure shingles or roof panels. Their corrosion-resistant coatings make them suitable for outdoor use, ensuring that the nails won’t rust or degrade over time, even when exposed to moisture and weather conditions.

3. Subflooring

Plastic strip nails are also commonly used in subflooring projects, where securing plywood or other materials to joists is necessary. The strength and durability of these nails ensure that the subfloor remains sturdy and stable, even under heavy loads.

4. Decking

For outdoor decking projects, nails offer an efficient way to fasten deck boards to the frame. Their corrosion-resistant properties make them an excellent choice for outdoor environments, ensuring the longevity of the deck.

5. Siding

In siding installations, plastic strip nails provide a secure and fast way to attach siding panels to the exterior of a building. The plastic strip ensures smooth feeding into the nail gun, allowing for quick and precise siding installation.

Contact Information

UNITED NAIL PRODUCTS CO., LTD

Specializing in high-quality nails and small coil wire production!

Thank you for reading this article, hope the information is useful to you.